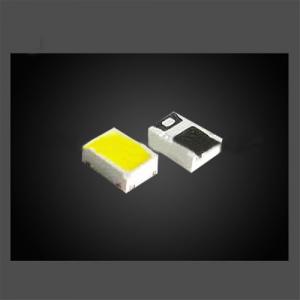

High Lumen 60-65Lm White SMD LED 5730 For LED Bulb

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1 Pc pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications for 5730 smd led white color

| Model | Power | color | intensity | voltage | current | view angle | CCT |

| SL-WZ5730-EM | 0.5w | white | 60-65lm | 2.8-3.5v | 150mA | 120deg | 5500-6000k |

| SL-IZ5730-EM | 0.5w | warm white | 55-60lm | 2.8-3.5v | 150mA | 120deg | 2850-3150k |

(Electro-Optical Characteristics(Ta=25°C)

Parameter | Test condition | Symbol | Value |

Forward voltage | If=150mA | Vf | 2.8-3.5v |

Luminous Flux | If=150mA | Φ | 60-65lm |

Viewing angle at 50% Iv | If=150mA | 2θ 1/2 | 120 Deg |

Reverse current | Vr=5v | Ir | 10µA |

Ra | If=150mA | Ra | 70/80/90 |

Absolute maximum ratings (Ta=25°C)

Parameter | Symbol | Value |

Power dissipation | Pd | 700mW |

Forward current | If | 200mA |

Reverse voltage | Vr | 5V |

Operation temperature range | Top | -35~+85°C |

Storage temperature range | Tstg | -40~+100°C |

Pulse forward current | Ifp | 250mA |

Electrostatic discharge | ESD | 2000(HBV)V |

Soldering temperature | Tsld | 260°C for 10 seconds |

Junction temperature | Tj | 105°C |

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By Sea | 30-40 business days |

1. 3-5 business days for Sample Orders; 7-15 business days for Bulk Orders for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q: Indoor full color LED display module and LED what is the difference between a full color?

- The classification of the LED display according to the installation environment: indoor LED display screen, semi outdoor LED display, outdoor LED display; according to color: color LED screen, dual color LED display screen, LED display screen, the color LED display screen; according to the functional area can be divided into graphic screen, screen, screen, screen, digital dot matrix digital hybrid screen.

- Q: What should I notice when I want to solder 1206 LED patch type luminous tube on fine copper wire?,

- It is best to use a hot-air gun heat transfer high air volume adjustable low moment welding, the specific heat jump to the appropriate place to see what you use what kind of welding wire, welding wire of different because of the different melting point impurities also some differences. The air volume is too high, easy to blow the original

- Q: LED light SMD LED package in what form, trouble you under the guidance of...

- The LED chip has bumps and is welded to the PCB board using FLIP CHIP to packaging technology.LED is English light emitting diode (light emitting diode) abbreviation, its basic structure is a electroluminescent semiconductor chip light emitting materials, with silver glue or glue curing to the bracket, connecting a chip and a circuit board and then with silver or gold, then sealed with epoxy resin around, to protect the internal core role finally, the installation shell, so the seismic performance of LED lamp is good. Field of application involves mobile phones, desk lamps, household appliances and other daily household electrical appliances and machinery production.

- Q: What, in what way do I shunt the LED?

- The voltage problem is determined by the size of your POWER SUPPLY, according to Ohm's Law: the series voltage is accumulated and the shunt voltage is the same.

- Q: Is the forward voltage drop of the patch LED too large or too small?

- The pressure drop in the normal range is generally better. The smaller the pressure drop, the lower the power dissipation. The more you save the electricity bill.But not to say that the smaller the better, not in the normal range of low pressure drop products may be defective.In addition, the uniformity of the LED pressure drop is also important.

- Q: Patch LED market conditions

- Chinese suppliers also offer mature, but less profitable two-color and trichromatic products, which are mostly used in backlighting, appliances, consumer products, consumer electronics and display. Despite low market demand, vendors continue to offer sideview SMD LED, including 335 (4008), 020 (3806) and 215 (2810)

- Q: What are the storage requirements of SMT patch LED (LED)?

- Keep in storage- the original sealing bag packing in the condition of the <40 C and <90% RH degrees for 12 months, more than the storage period will bake.Please check the leak before opening the packing bagIn opening the sealed bag, should be placed in SMD LED and C 60%RH. < < 30 degrees under the conditions in the above conditions, SMD LED must be in the open package using reflow within 24 hours. If placed more than 24 hours, you need to bake- baked, SMD LED in C + 80 degrees 5 degrees C and <=10%RH relative humidity in the oven for 24 hours? remove the pouch before baking, and do not open the oven door frequently

- Q: What is the difference in performance between the LED plug-in and the LED patch?

- No difference, because the core of the two is the same, are diode PN junction, but no packaging, the production process is a little different

- Q: The quality of the LED patch module

- Chip size. The larger the size of the same chip, the higher the general brightness, the stronger the bearing capacity, the higher the stability performance, of course, the price is relatively high. The size of the module chips now includes: 9MIL, 10MIL, 12MIL, 14MIL, 23MIL, and so on.

- Q: Such as title, please have welding patch LED lamp experience expert guidance, do not search from the Internet to the theoretical knowledge, thank you!

- When soldering, the temperature is best to be lower, and the average welding temperature is about 360. That's enough, because the melting temperature of the tin wire is about 220 degrees, so if it is allowed, the temperature can be reduced as low as possible.

Send your message to us

High Lumen 60-65Lm White SMD LED 5730 For LED Bulb

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1 Pc pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords