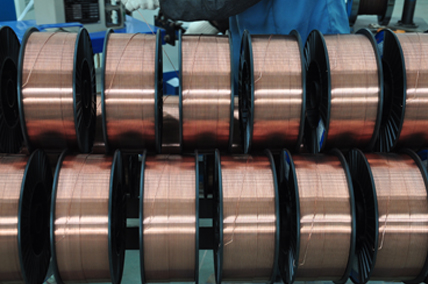

High grade solder wire

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Welding wire product introduction:

Main varieties of carbon steel wire, stainless steel wire, aluminum and aluminum alloy wire, alloy steel welding wire, submerged arc welding wire, etc., specifications for Ф 0.8 ~ 1.6 mm.

1. Carbon steel, low alloy steel solid core gas shielded welding wire:

Representatives of YS - MG49-1, YS - MG70S - 2, YS - MG70S - 3, YS - MG70S - 4, YS - MG70S - 6, YS - MG70S - 7, YS - MG70S - G (MG50 - Ti), YS - MG70S - G (MG50 - Ni), YS - MG70S - G (MG50 - HTC), YS - MG80S - G (MG55 - TiB), YS - MG80S - G (MG55 - MoTi), YS - MG80S - G (MG55 - CrNi);

2. The weathering steel gas shielded welding wire, on behalf of the brand YS - MG44 - G (H08MnSiCuCrNiI), YS - MG44 - G (H08MnSiCuCrNi Ⅱ);

3. Stainless steel gas shielded welding wire, on behalf of the brand YS - MG308, YS - MG308H, YS - MG308L, YS - MG308LSi, YS - MG309, YS - MG309Mo, YS - MG309L, YS - MG309LMo, YS - MG309LSi, YS - MG310, YS - MG316, YS - MG316L, YS - MG316LSi, YS - MG317, YS - MG317L, YS - MG318, YS - MG321, YS - MG347;

4. The submerged arc welding wire:

On behalf of the brand YSSA - H08A, H08E, YSSA H08

MnA, YSSA - H10Mn2, YS - YJ500 - P, YS - YJ501, YS - YJ501Ni, YS - YJ502, YS - YJ502Ni, YS - YR302, YS - YR307M, YS - YR312M, YS - YR317 - P, YS - YR309M, YS - YR402, etc.

he class of rolling

Most of the welding wire belong to such, including low carbon steel wire, alloy structural steel wires, alloy structural steel welding wire, stainless steel wire and non-ferrous metal wire and so on.

Common welding wire:

56 ~ 58 HRC SKD11 > 0.5 ~ 3.2 mm weld cold working steel, metal stamping die, die cutting, cutting tools, forming mold, workpiece hardfaced with high hardness, wear resistance and high toughness of the argon welding, heat preheating before welding repair, otherwise easy to generate crack phenomenon.

63 - degree blade edge wire > 0.5 ~ 3.2 mm HRC 63 ~ 55, is mainly used in welding knife mold, high hot hardness modulus, hot forging die, hot stamping die, screw die, good wear resistance hardfacing and high speed steel, blade repair.

SKD61 > 0.5 ~ 3.2 mm HRC 40 ~ 43 welding, aluminum die casting, zinc supplementation with good heat resistance and crack resistance, heat punching die of copper, aluminum, copper hot forging die, aluminum die-casting die, good heat resistance, abrasion resistance, resistance to cracking. Tortoise shell crack shape are common general hot pressing molding, mostly caused by thermal stress, also has caused by surface oxidation or die casting material corrosion, heat treatment to improve its hardness appropriate life, hardness too low or too high does not apply.

70 n > 0.1 ~ 4.0 mm wire characteristics and purposes: high hardness of steel joint, zinc aluminum die-casting die cracking, weld reconstruction, pig iron/cast iron weld repairs. Can be directly welding all kinds of cast iron/cast iron materials, can also be used as a mold cracking of weld, using cast iron welding, low electricity will exile, as far as possible with the short arc welding, steel parts of preheating, heating and slow cooling after welding.

60 e > 0.5 ~ 4.0 mm features and use: the special welding joint of high strength steel, hard facing of production base, cracking of the weld. High strength wire, nickel chromium alloy composition, high professional used to prevent rupture of the underlying welding, filling with render, strong tension, and steel can be repaired after welding cracking phenomenon. Tensile strength: 760 N/mm&sup 2; Ting rate: 26%

8407 - H13 > 0.5 ~ 3.2 mm HRC 43 ~ 46 zinc, aluminum, tin and other non-ferrous alloy and copper alloy die-casting mould, can be used as a hot forging or stamping die. With high toughness, good wear resistance and thermal corrosion prevention, resistance to high temperature to soften, anti high temperature fatigue sex good, can weld hot punch, reamer, rolling knives, cutting knives, scissors... Do heat treatment, such as to prevent the decarburization, produced by hot tool steel after welding high hardness is prone to rupture.

- the blowout backing welding wire > 0.5 ~ 2.4 mm joint of HB - 300 high hardness steel, hard facing of production base, cracking of the weld. High strength wire, nickel chromium alloy composition is high, is used to prevent rupture of the underlying, backing welding, filling, strong tension, and can repair the crack of steel welded reconstruction.

718 > 0.5 ~ 3.2 mm HRC 28 ~ 30 large household appliances, toys, communication, electronics, sports equipment and other plastic die steel products. Plastic injection mould, heat-resisting mold, corrosion resistance, good machinability, engraved, excellent surface gloss, after grinding the long service life. After preheating temperature of 250 ~ 300 ℃ heat temperature of 400 ~ 500 ℃, for multilayer welding time, welding repair by backward method, is not easy to produce the defects such as poor convergence and.

738 > 0.5 ~ 3.2 mm 32 ~ 35 HRC translucent and needs to have surface gloss of plastic die steel products, large mold, product of complicated shape and high precision plastic mold steel. Plastic injection mold, heat resistant mold, mold, erosion corrosion resistance is good, can have excellent processability, free cutting and polishing and electrolytic corrosion, toughness and wear resistance. After preheating temperature of 250 ~ 300 ℃ heat temperature of 400 ~ 500 ℃, for multilayer welding time, welding repair by backward method, is not easy to produce fusion and defects such as bad.

P20Ni > 0.5 ~ 3.2 mm HRC 30 ~ 34 plastic injection mold, heat-resistant die casting (copper). With low welding crack sensitivity of the alloy composition design, nickel by about 1%, suitable for PA, POM, PS, PE, PP, ABS plastic, good polishing sex, no porosity, crack, after welding of grinding has good finish, after vacuum degassing, after forging, hard to HRC 33 degrees, cross section of uniform hardness distribution, die life of more than 300000. After the preheating temperature of 250 ~ 300 ℃ heat temperature of 400 ~ 500 ℃, for multi-layer welding stoppage, backward method is used to weld repairs, less is produced Defects such as bad and raw fusion.

NAK80 > 0.5 ~ 3.2 mm HRC 38 to 42 plastic injection mold, mirror steel. Discharge efficiency is very high, high hardness, mirrors, good workability, excellent welding performance, after grinding, smooth as a mirror, as the world's progress, the best mold steel, easy cutting elements, easy machining, high toughness and wear no deformation characteristics, suitable for all kinds of transparent plastic die steel products. After preheating temperature of 300 ~ 400 ℃ heat temperature of 450 ~ 550 ℃, for multilayer welding time, welding repair by backward method, is not easy to produce fusion and defects such as bad.

S136 > 0.5 ~ 1.6 mm HB - 400 plastic injection mould, corrosion resistance, good permeability. High purity, high mirror, polishing, rust prevention acid resistance, heat treatment deformation, less suitable for PVC, PP, EP, PC and PMMA plastics, corrosion resistance and easy processing module and fixture, super mirror surface corrosion resisting precision mould, such as rubber mold, camera parts, lens, case, etc.

Huangpai HB200 iron steel > 0.5 ~ 2.4 mm mould, shoes mould, mild steel welding, sculpture engraved, S45C, S55C steel repair, etc. Quality is fine, soft, easy to machining, there would be no air hole, after the preheating temperature of 200 ~ 250 ℃ heat temperature of 350 ~ 450 ℃.

BeCu (beryllium copper) > 0.5 ~ 2.4 mm HB300 high thermal conductivity of copper alloy mold material, main elements for beryllium, it is suitable for plastic injection molding mould insert, the mold core, die casting, punch, hot runner system, cooling thermal conductive mouth, the whole of the blow molding mold cavity, wear plate, etc. Tungsten copper materials are used in resistance welding, electric spark, electronic packaging, and precision machinery equipment, etc.

- Q: What are the different types of steel wire rod surface cleaning processes?

- Various industries commonly utilize different types of processes to clean the surface of steel wire rods. These processes aim to eliminate contaminants like rust, scale, dirt, and oil, ensuring that the wire rod is clean and ready for further use or processing. The most frequently employed steel wire rod surface cleaning processes are as follows: 1. Pickling: In this process, the wire rod is submerged in an acid solution, typically hydrochloric acid, to eradicate surface impurities. The acid reacts with the contaminants, dissolving them and leaving the wire rod clean. 2. Shot blasting: Shot blasting involves propelling abrasive particles, such as steel shots or grits, onto the wire rod's surface at high velocity. This abrasive action removes rust, scale, and other impurities, resulting in a clean and textured finish. 3. Wire brushing: Wire brushing is a mechanical process that utilizes wire brushes to scrub the wire rod's surface. This process effectively removes loose rust, dirt, and other contaminants. 4. Chemical cleaning: Chemical cleaning entails the application of specific chemical agents to the wire rod's surface. These agents react with the contaminants, breaking them down and facilitating their removal. 5. Ultrasonic cleaning: Ultrasonic cleaning employs high-frequency sound waves to generate microscopic bubbles in a cleaning solution. These bubbles implode on the wire rod's surface, creating a scrubbing action that eliminates contaminants. 6. Electrochemical cleaning: Electrochemical cleaning, also known as electrocleaning, employs an electric current to eliminate surface impurities from the wire rod. The wire rod is immersed in an electrolyte solution, and the electric current causes the contaminants to dissolve. Each of these steel wire rod surface cleaning processes possesses its own advantages and limitations. The selection of a process depends on factors such as the type and severity of contamination, the desired level of cleanliness, and the specific requirements of the application.

- Q: How is steel wire rod used in the manufacturing of wire for elevator counterweights?

- Steel wire rod is an essential component in the manufacturing of wire for elevator counterweights. The process begins with high-quality steel wire rods, which are typically made from carbon or alloy steel. These rods are subjected to a series of manufacturing processes to transform them into wire that meets the specific requirements for elevator counterweights. Firstly, the steel wire rods are cleaned and descaled to remove any impurities or surface contaminants. This ensures that the wire produced is of the highest quality and has excellent corrosion resistance. Next, the rods go through the process of drawing, where they are pulled through a series of dies to reduce their diameter and increase their length. This process imparts the desired tensile strength and flexibility to the wire. After the drawing process, the wire is usually annealed to relieve any internal stresses and enhance its ductility. This involves heating the wire to a specific temperature and then slowly cooling it. Annealing not only improves the mechanical properties of the wire but also enhances its resistance to fatigue and wear. Once the wire has been drawn and annealed, it undergoes surface treatment processes such as coating or galvanizing. Coating the wire with a protective layer, such as zinc or epoxy, helps to prevent corrosion and extend its lifespan. Galvanizing involves dipping the wire into a bath of molten zinc to create a protective zinc coating, which provides excellent corrosion resistance. Finally, the coated or galvanized wire is further processed to achieve the desired shape and size for elevator counterweights. It can be cut into specific lengths or wound onto spools for easier handling during the manufacturing process. The wire is then used to form the internal structure of elevator counterweights, which are crucial for balancing the elevator car and ensuring its smooth operation. In summary, steel wire rods play a vital role in the manufacturing of wire for elevator counterweights. They are subjected to various processes, including cleaning, drawing, annealing, and surface treatment, to produce high-quality wire with the necessary strength, flexibility, and corrosion resistance. This wire is then used to construct the internal structure of elevator counterweights, ensuring the safe and efficient operation of elevators.

- Q: How does the tensile strength of steel wire rod vary with different grades?

- The tensile strength of steel wire rod can vary significantly with different grades. The grade of steel refers to its composition and the specific properties it possesses. Generally, higher grade steel wire rods have higher tensile strength. Different grades of steel wire rod contain varying amounts of carbon, manganese, silicon, and other elements. The composition of the steel influences its strength, hardness, and other mechanical properties. Steel wire rods with higher carbon content, for example, tend to have higher tensile strength. Additionally, the manufacturing process used to produce steel wire rod can also affect its tensile strength. The steel can be subjected to various heat treatment processes such as quenching and tempering, which can further enhance its strength. In summary, the tensile strength of steel wire rod varies with different grades due to differences in composition and manufacturing processes. Higher grade steel wire rods generally have higher tensile strength, allowing them to withstand greater forces and pressures.

- Q: What are the advantages of using galvanized steel wire rod?

- Galvanized steel wire rod offers numerous benefits. Firstly, its zinc coating ensures a high level of corrosion resistance, making it ideal for outdoor use in moist and harsh weather conditions. Secondly, this type of wire rod is exceptionally durable, thanks to the added layer of protection provided by the zinc coating. Consequently, it can withstand heavy loads without breaking or deforming. Its durability makes it perfect for demanding applications such as construction and fencing. Furthermore, galvanized steel wire rod is highly versatile, easily adaptable to different applications. It can be bent, twisted, and cut to meet various industry needs, including agriculture, automotive, and manufacturing. This versatility allows for the creation of products like fences, wire mesh, and springs. Additionally, galvanized steel wire rod proves to be cost-effective in the long run. Although the initial galvanization process may require a higher investment than other steel types, its corrosion resistance and durability minimize maintenance requirements and extend its lifespan. Consequently, the need for frequent replacements is reduced. Lastly, galvanized steel wire rod is environmentally friendly. The non-toxic and recyclable nature of the zinc coating used in the galvanizing process ensures that the wire rod can be easily recycled at the end of its lifespan, thereby reducing waste and minimizing its environmental impact. In conclusion, the advantages of galvanized steel wire rod encompass its high corrosion resistance, durability, versatility, cost-effectiveness, and environmental friendliness. These qualities make it the preferred choice for a wide range of applications in various industries.

- Q: What are the main factors influencing the choice of steel wire rod order payment refund options?

- The main factors influencing the choice of steel wire rod order payment refund options can vary depending on various factors. However, some common factors that play a significant role in this decision-making process include: 1. Supplier Reputation: The reputation and trustworthiness of the supplier is a crucial factor. Buyers tend to choose payment refund options that provide them with a sense of security in case of any issues or disputes with the supplier. 2. Order Volume and Value: The size and value of the steel wire rod order can impact the choice of payment refund options. Larger orders with higher values may require more secure refund options to mitigate potential financial risks. 3. Payment Terms and Conditions: The payment terms and conditions set by the supplier can influence the choice of refund options. Some suppliers may offer specific refund options based on their preferred payment methods, such as bank transfers, letters of credit, or escrow services. 4. Buyer's Financial Capability: The financial capability of the buyer can also determine the choice of refund options. Buyers with limited financial resources may opt for payment refund options that offer flexibility and minimize risks, such as installment payments or delayed payment terms. 5. Delivery and Quality Assurance: The reliability and quality assurance provided by the supplier can impact the choice of refund options. Buyers may prefer refund options that allow them to inspect the steel wire rod upon delivery and ensure compliance with the agreed specifications before making full payment. 6. Market Conditions and Competition: Market conditions and competition among suppliers can influence the choice of refund options. Buyers may consider refund options that are more favorable or competitive in the market, such as cash discounts or rebates. 7. Legal and Regulatory Considerations: Legal and regulatory requirements in the buyer's jurisdiction can also affect the choice of refund options. Buyers may opt for refund options that comply with local regulations and provide legal protection in case of any disputes or non-compliance. It is important for buyers to carefully evaluate these factors and assess their specific needs and preferences before deciding on the most suitable payment refund options for their steel wire rod orders.

- Q: What are the common methods used to protect steel wire rod from corrosion?

- There are several common methods used to protect steel wire rods from corrosion. These methods include: 1. Galvanization: Galvanization is a process in which a layer of zinc is applied to the surface of the steel wire rod. This layer acts as a sacrificial anode, meaning it will corrode instead of the steel when exposed to moisture or other corrosive elements. 2. Coating: Coating the steel wire rod with a protective layer is another effective method to prevent corrosion. Various types of coatings can be used, such as epoxy, polyethylene, or polyurethane. These coatings create a barrier between the steel and the surrounding environment, preventing moisture or corrosive substances from coming into direct contact with the metal. 3. Cathodic Protection: Cathodic protection is a technique that involves applying a direct electrical current to the steel wire rod. This current creates a protective electrochemical reaction, preventing the steel from corroding. This method is commonly used in environments where the steel is exposed to highly corrosive conditions, such as in marine or underground applications. 4. Proper Handling and Storage: Ensuring that steel wire rods are handled and stored correctly is crucial in preventing corrosion. This includes keeping the rods in a dry and well-ventilated area, away from moisture or corrosive substances. Additionally, using proper lifting and transportation methods can prevent damage to the rods' protective coatings or galvanized layer, which could lead to corrosion. 5. Regular Inspection and Maintenance: Regularly inspecting the steel wire rods for signs of corrosion and performing necessary maintenance can help prevent further deterioration. This may include removing any rust or damaged coatings, applying touch-up coatings, or re-galvanizing the rods if necessary. It is important to note that the choice of corrosion protection method will depend on various factors, such as the specific application, environmental conditions, and budget constraints. Consulting with corrosion experts or engineers can help determine the most suitable method for protecting steel wire rods from corrosion.

- Q: Can decarburization occur in low carbon and low alloy wire rods? Why?

- Therefore, low carbon alloy steel may also be decarburization, the normal production process and good surface quality, there will be no high carbon steel such as all decarburization layer, but local is also possible!

- Q: What are the different types of steel wire rod surface cleaning methods for wire galvanizing?

- Wire galvanizing requires the use of various steel wire rod surface cleaning methods to eliminate impurities and contaminants. These methods are specifically designed to prepare the wire rod for the galvanizing process. One commonly used technique is acid pickling, which involves immersing the wire rod in a bath containing hydrochloric acid or sulfuric acid. The acid effectively dissolves mill scale, rust, and other contaminants, leaving the wire rod clean and ready for galvanizing. Another method, mechanical descaling, employs mechanical means such as abrasive brushes or shot blasting to physically eliminate surface impurities. This method is ideal for wire rods with heavy scale or stubborn contaminants that cannot be easily removed through acid pickling alone. Additionally, there is the electrolytic cleaning method, which utilizes an electric current to eliminate surface impurities. The wire rod is submerged in an electrolyte solution, and the electric current causes the impurities to migrate away from the wire rod towards the opposite electrode. This method is typically employed for wire rods with a thin layer of oxide or other surface contaminants. Lastly, mechanical cleaning involves using mechanical means like wire brushing or sanding to scrub the wire rod's surface and eliminate any impurities. This method is suitable for wire rods with light scale or surface contaminants that can be easily removed through mechanical means. Ultimately, the selection of a cleaning method depends on the specific requirements and condition of the wire rod. Each method has its own advantages and disadvantages in terms of effectiveness, cost, and environmental impact.

- Q: What are the different surface defects that can affect the fatigue strength of steel wire rod?

- Some of the different surface defects that can affect the fatigue strength of steel wire rod include scratches, pits, cracks, and decarburization. These defects can act as stress concentrators, leading to an increased likelihood of fatigue failure.

- Q: How is steel wire rod used in the manufacturing of wire mesh fencing?

- Steel wire rod is used in the manufacturing of wire mesh fencing as it serves as the primary raw material. The wire rod is first drawn into the desired thickness and then woven or welded to create the wire mesh. The strong and durable nature of steel wire rod ensures that the resulting wire mesh fencing is capable of withstanding external forces and providing security and containment in various applications.

Send your message to us

High grade solder wire

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords