high efficiency jaw crusher used for mineral PE 600*750

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Jaw stone crusher machine:

1.ISO9001:2000

2.Price:negotiable

3.Capacity:5-800T/H

4.Payment terms:L/C or T/T

Jaw stone crusher machine:

1.ISO9001:2000

2.Price:negotiable

3.Capacity:5-800T/H

4.Payment terms:L/C or T/T

Jaw Crusher Description

The jaw crusher we offers are ideal for primary and secondary crushing. Jaw Crusher is one of the main types of primary crushers in a mine or ore crushing process plant and also is one of the most widely used crushing equipments in mining industry.We are famous jaw crusher manufacturers in China, and sold crusher machines to all over the world. This series of jaw crusher can reach the crushing ratio of 4-6 and the shape of final product is even. Because it is primary crusher, Jaw crusher is designed for long life service with minimum maintenance for hard, tough, abrasive material and overload high capacity

Jaw Crusher Working Principle

Primary jaw crusher is typically of the square opening design, and secondary jaw crusher is of the rectangular opening design. Jaw Crusher reduces large size rocks or ore by placing the rock into compression. A fixed jaw board, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary plate. The space at the bottom of the "V" aligned jaw plates decide the crusher product size gap, or the size of the crushed product from the jaw crusher. The rock remains in the jaw until it is small enough to pass through the gap at the bottom of the jaws.

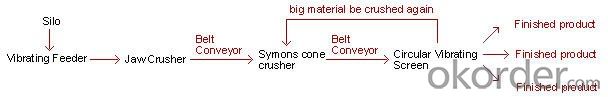

Brief introduction to stone crushing & screening plant

we manufactures various equipments for whole set of stone production line, and provide complete technical support for customers. The whole production line consists of Vibrating Feeder, Jaw Crusher, Impact Crusher, vibrating screen, Belt Conveyor, electric control cabinet and etc.

We design different production lines ranging 50 t/h to 500 t/h by combining different models of equipments.It is widely used for crushing hard limestone, granite, basalt, gravel, metallurgic slag, etc or artificial sand making for hydroelectric power, building material, high way, city construction, etc. Different models of equipments are combined to meet different customers' demands according to different craft requirements.

Process of stone crushing & screening plant

1. Big rocks are transported to the working site of stone production plant from quarry.

2. The rocks are transferred to primary crusher by vibrating feeder. Once there is a hopper prior to the vibrating feeder, the rocks are stored in the hopper firstly.

3. The crushed materials are transferred to Impact Crusher by Belt Conveyor for secondary crushing.

4. The materials are transferred to the vibrating screen, and screened into different sizes.

5. Those aggregate with suitable size will be transferred to the final product pile; while those with unsuitable size will be transferred to the Impact Crusher for re-crushing.

This forms a closed circuit manifold cycles. The sizes of final products will be graded and separated according to customers' requirements and application, and the deduster will be attached for the sake of environment protection.

Main advantages of stone crushing & screening plant

1. Customerized design

The production line is designed according to customer's requirement on the output size, types of output and capacity, as well as other factors such as material property, site conditions and purpose.

2. High efficiency and low cost

The arrangement of the machines in the production line can work efficiently and act for the maximum effect, which can ensure the efficiency and increase the output in unit time so that to lower the average cost of finished product (per ton).

3. Standard component

It is much convenien for replacement and maintenance of the machines. Shorten the shutdown time resulted from those maintenance.

4. Optimized production flow

The optimized production flow can ensure the capacity of the whole production line, the density of piling up and the shape of finished product, to satisfy the various purpose of product.

- Q: Is it possible between two people driving to make it there within a 24 hour period?

- Giant Hot Head LC Jet Vac Legendary 3 pack Legendary bouncer Granite Crusher (target exclusive) are also available right now. limited supply but can be found. legendary stealth elf is available in the UK and should be in the US soon. I dont know about wave 3 and who is in it.

- Q: If we are driving and we hit alot of speed bumps in a row it's instant erection. There's no hiding it. What could be the cause of such an odd reaction?

- No, it wasn't truly. The Treaty of Tripoli says the authorities wasn't, and the first 2 presidents agreed with it. most of the most influential of the Founding Fathers were Deists whose conception is that God created the universe in such way that it may perform on its own and takes no further area in it. some, exceedingly Thomas Jefferson, went from Deism to atheism, as his writings tutor. there are countless proofs that the authorities wasn't in accordance with Christianity. i'm a Christian, and that i comprehend the Bible says to, Render unto Caesar what's Caesar's, so that is acceptable to well known that the country wasn't in accordance with Christian values. Lies accomplish not something for every person. they in common words discredit the liars.

- Q: Are you *patiently* working with others as God would have us be, when answering questions, or are you more the crusher type?

- I used to be quite patient and I should be, but ever since I joined here, you get a lot of people who fail in many aspects. Knowledge being number 1. So when they argue with you over time, you lose the patience and become the crusher type.

- Q: None of my power locks work nor do the interior lights come on. I have checked the bulbs and they are fine. I have gone through the fuses under the dash and in the engine compartment and all are fine. I have not checked the relays under the dash yet as I do not know how to test them. When the buttons are tried on the locks, the is no sound to indicate any effort on the part of the solenoid. I can manually lock them but the buttons are really stiff and hard to move. Any thoughts would be greatly appreciated.ThanksScott

- If you go at them at an angle you will increase the likelihood of losing the back on the camber, or on a lower bike like a cruiser grounding the footpegs. If you go at it fast enough to bottom the bike on it, you are going too fast. Personally, with no worries of bottoming out, I give it a little shot of throttle as I go up which helps extend the forks, so it lands the other side with full travel, this will smooth out the hump.

- Q: Is a single jaw crusher easy to use?

- The single jaw jaw crusher is the exclusive patented product of Yiwu black and white Mining Machinery Co., Ltd., which has the unique functions of energy saving, consumption reduction and production increase:1, single jaw crusher eliminates the congenital defects of traditional jaw crusher mechanical structure exists "stress state", it will change to the "reinforcement effect", the mechanical structure of the jaw crusher models is more scientific and reasonable.2, to achieve the "two broken" and "a machine three machine broken, can be directly 500mm the following bulk materials broken into 5mm disposable as sand or powder, for the jaw crusher this" coarse broken "models to achieve" fine "(sand) function open the door.

- Q: THE CAN CRUSHER IS ON TOP AND ONCE CRUSHED THE CAN FALLS INTO THE TRASH CONTAINER

- They're pretty expensive. You may want to just get a separate crusher to use with your existing trash cans.

- Q: I want to buy a stone crusher , but I am hesitating between the symons cone crusher and portable crusher, who can tell me what should I do ?

- And which models have you been considering to choose from?

- Q: Hydraulic cone crusher and spring cone crusher which good?

- Hydraulic cone crusher is suitable for medium and medium hardness materials for medium and fine crushing operations. Especially in the product grain shape strict requirements, high yield requirements, high degree of automation of the broken production line is the preferred use.

- Q: I've attempted to knock the lid against the counter top. no dice. i also ran it under warm water and i hit it with a knife to break the seal. also no dice. any other suggestions?

- No saran wrap would not do the same thing because it is a different material and subject to tearing. The point of a dental dam? To protect you from contracting an STD when you engage in oral sex. Why protect yourself? Because no matter how good the sex is, it is not worth dying for!

- Q: Do any of yall know how to access sites in school?

- it is going to purely be used to place out a fireplace, and not for something. fireplace blankets are designed to smother flames and restrict oxygen, utilising a fireplace blanket on a toddler ought to reason suffocation.

Send your message to us

high efficiency jaw crusher used for mineral PE 600*750

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches