High Corrosion Resistance Magnesite Brick for Cement Kilns

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Magnesite Brick

CMAX magnesite brick is made of various grades of magnesia and is a kind of alkali resistance refractory brick.

Image of Magnesite Brick

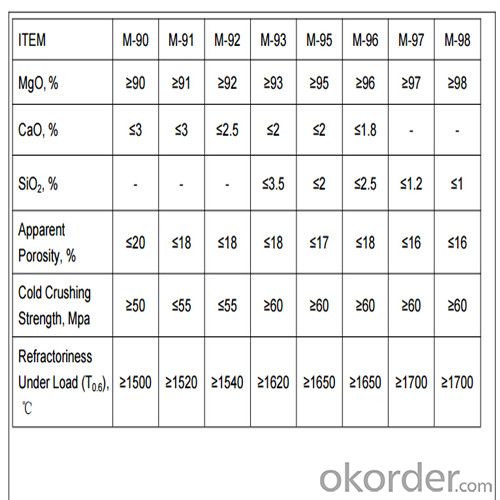

Technical Data of Magnesite Brick

Feature of Magnesite Brick

Good high-temperature performance

High thermal shock resistance

Application of Magnesite Brick

Open hearth futnace

Non-ferrous furnace

Glass tank regenerators

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: What is the ratio of magnesia refractory bricks to brine? For example, what is the difference between the 97 and 95 with 92 brick brick brick material mixed with brine ratio?

- In addition to the brine binder burned magnesia brick and sulfite pulp waste liquid, Magnesium Sulfate solution binder is generally around 3%

- Q: Brick price?

- There are various series of unshaped refractory gunning, magnesia ramming material, mending material, coating material, dry lining material, composite refining agent, covering agent, tundish and tundish slag wall, ladle drainage sand and electric furnace taphole filler etc..

- Q: The index of magnesia brick

- indexMGe-20 MGe-16 MGe-12 MMGe-8 DBMK-A DBMK-B DBMK-C MgO≥(%) 40 45 55 60 80 80 80 Cr2O3≤(%) 20 16 12 8 6-8 6-8 6-8 SiO2≤(%) --- --- --- --- 2.0 2.5 3.0

- Q: High purity magnesia brick masonry mortar for what?

- High purity aluminum is 99.99, the first is not pollution, the stove is high magnesia brick masonry, 95% and 97% purity magnesia brick is for a long time did not find a good bit of fireclay, do not know what to build, now used light burned US powder and heavy burned magnesium plus brine built, with 2 months a griddle doesn't stick on magnesium brick, a touch off, there is no good sintering

- Q: Manufacture of various refractory magnesia brick mainly comes from Magnesium Oxide, what kind of ore?

- The ore quality requirements of MgO = 41%, CaO = 6%, SiO2 = 5%. The resources of magnesite in China are rich. The types of deposits include sedimentary metamorphic deposits, sedimentary hydrothermal metasomatic deposits and weathering leaching deposits.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- High alumina brick clay brick up to 1700 degrees above 1500 degrees -1750 degrees of magnesia brick and magnesia chrome brick 1500-1650 degrees, I is the production of clay brick, brick my temperature at 1500-1700 degrees. Specific depends on what kiln, brick is only part of it

- Q: With different capacitance magnesia brick brick

- It has good thermal stability, corrosion resistance and spalling resistance. Widely used in converter, arc furnace and other industrial furnace lining refractory.

- Q: Magnesia brick

- General can be divided into sintered magnesia brick (also called burnt magnesia brick) and chemically bonded magnesia brick (also known as the two major categories of not burned magnesia brick). Purity and high firing temperature of magnesia, due to the direct contact of periclase grains, known as direct bonded magnesite brick; made of fused magnesia bricks called electrically fused magnesite brick.

- Q: Magnesite chrome brick, magnesia chrome brick indicators? What is the price?.

- According to the actual situation, design the brick you need, and the price of brick is determined by the index.

- Q: Combined with the ordinary clay brick and magnesia brick as an example, the existence of impurities in minerals and refractories production main components of the formed liquid relative what affect the performance.

- Also known as clay brick brick, is a man-made small bulk building, clay brick clay (including shale, coal gangue powder) as the main raw material, through mud processing, molding, drying and roasting, solid and hollow.

Send your message to us

High Corrosion Resistance Magnesite Brick for Cement Kilns

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords