High Alumina Brick - Light Weight Insulating Refractory Bricks for Kiln Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description for High Alumina Fire Brick:

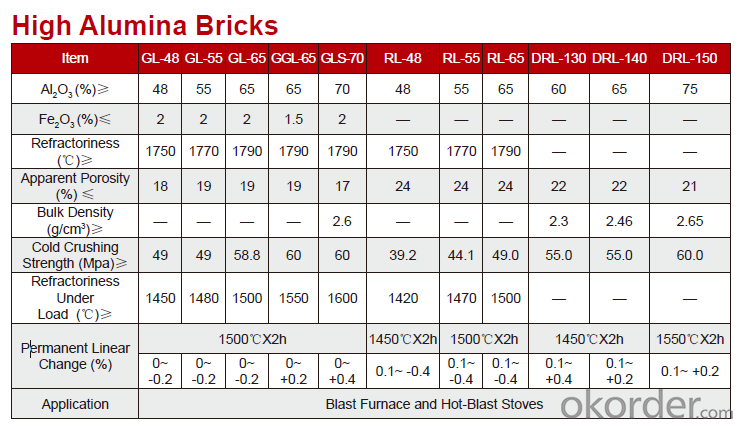

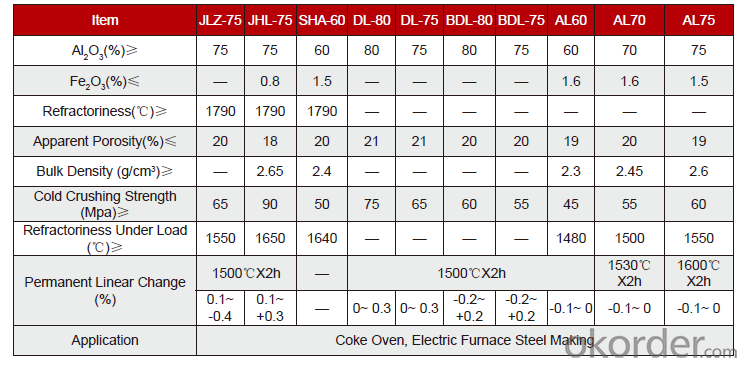

CNBM High Alumina Fire Brick are classified according to alumina content ranging from 48% to 90%. The kiln shell is made from rolled mild steel plate, usually between 15 and 30 mm thick, welded to form a cylinder which may be up to 230 m in length and up to 6 m in diameter. This will be usually situated on an east/west axis to prevent eddy currents.

Upper limits on diameter are set by the tendency of the shell to deform under its own weight to an oval cross section, with consequent flexure during rotation. Length is not necessarily limited, but it becomes difficult to cope with changes in length on heating and cooling (typically around 0.1 to 0.5% of the length) if the kiln is very long.

Product Applications:

CNBM High Alumina Fire Brick are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc.

Product Advantages:

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So pls stay cool with our quality.

Main Product Features:

◆Low thermal conductivity

◆Excellent acid and base slaging resistance

◆High refractoriness

◆Excellent thermal shock resistance

◆Excellent mechanical strength

◆Good spalling resistance and wear resistance.

◆Good corrosion resistance.

Product Specifications:

FAQ:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: How much is one ton of high alumina refractory brick?

- High alumina refractory brick according to the different content of AL2O3 is divided into grade, grade one and grade two, and grade three high aluminum brick, Zhengzhou Kang Hui refractories factory price in 800-1900 yuan / ton, stable quality, are exported to the domestic and foreign markets.

- Q: How are the high alumina bricks fired?

- Generally, the high alumina bauxite is added with a small amount of clay. After being ground, the gas is injected and shaped in the form of slurry by the way of gas attack or foam, and it is burnt at 1300~1500 DEG C. Sometimes industrial alumina can be used to replace part of bauxite clinker. Used for lining and thermal insulation of masonry kilns, as well as for areas where there is no high temperature, high melting material erosion and erosion effects. When touching the flame directly, the touch temperature shall not be higher than 1350 degrees.

- Q: How to reduce porosity of high alumina brick

- High alumina brick used as refractory products in refractory material, has a great application in masonry kilns, insiders pointed out that the quality of high alumina brick general porosity and it has a great relationship! So, how to reduce the porosity of high alumina brick rate is very important!

- Q: Which is better, the soft core or the hard core?

- The use of each of the single core copper wire with low line, 1.5 square with cap line home, socket 2.5 square, air conditioning to walk alone line 4 square can, when the terminal box into a socket with leakage protection switch, prevent overload and short circuit.

- Q: How much is one ton / ton of high alumina refractory brick?

- The price of high alumina refractory bricks is not equal, according to the quality index of GB2988-2012

- Q: What are the high temperature refractory mortars made of?

- Products used in metallurgy, building materials, machinery, chemical, power industry, industrial thermal furnace, for masonryBuilding clay brick, high alumina brick and corundum brick have the characteristics of full grey seam, good airtightness, high bonding strength, high temperature performance and suitable construction time

- Q: What are the specifications for bricks?

- Thecompressive node as a new type of building energy-saving wall materials, which can be used for masonry walls, but also has good thermal properties, in line with the construction of the building module, reduce the loss in the process of construction, improve work efficiency; the hole rate reached more than 35%, can reduce the weight of the wall, save the foundation engineering cost. Compared with common sintered porous brick, it has the characteristics of heat preservation, heat insulation, light weight, high strength and high construction efficiency. The product is made of shale as raw material. It is produced by high vacuum extrusion molding machine and one yard firing process

- Q: What's the weight of the refractory bricks?

- Referred to as refractory brick. Refractory made from refractory clay or other refractory material. Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C. Also called brick. Refractory material of a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick, refractory insulating bricks (Rong Zhuzhuan);

- Q: How does the physicochemical index change when the high alumina brick is used at high temperature?

- When the high alumina brick is used at high temperature, the physical and chemical indexes and other constants will not change if the temperature is in the physical and chemical indexes and the softening temperature of the load.

- Q: Which thermal shock stability of clay brick and high alumina brick is good?

- Generally, the thermal shock resistance of high alumina brick products is worse than that of clay brick products

Send your message to us

High Alumina Brick - Light Weight Insulating Refractory Bricks for Kiln Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords