High Alumina Brick for High Strength Glass Kiln Thermal Insulating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1044 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Alumina High Strength for Glass Kiln Thermal Insulating Brick

Product Description

The phosphate bonded high aluminum bricks are with high strength, low bulk density, low thermal, conductivity, high thermal shock resistance and the anti-spalling is good. Widely used in cement kiln,hot blast stove/furnace,EAF(electric arc furnace),coke oven door...

Structure& Advantage

for Our High Aluminum/Alumina Refractory Brick, Fireclay Bricks

1) Good thermal shock resistance

2) High-temperature endurable

3) Good thermal insulation

4) The using temperature is 1600 c

5) Phosphate high alumina bricks,iso

6) High strength

7) Low thermal conductivity

8) Widely used in cement kiln.

9) Low creeping rate

10) High pressure

11) Excellent thermal shock resistance

12) High quality fireclay clinker

We Are Suppiler for

Below are some of our customers

Allied Mineral Products,inc

Refractories Incorporated

Srs Sorg Refractory Systems GmbH,

Sunward Refractories Co.,Ltd

Lilama69-1 Joint Stock Company etc.

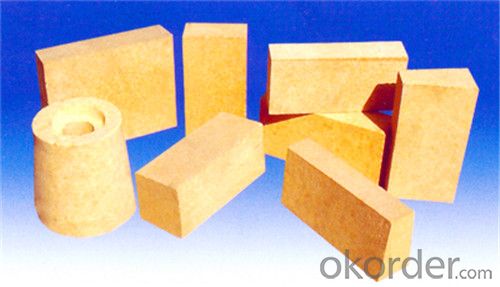

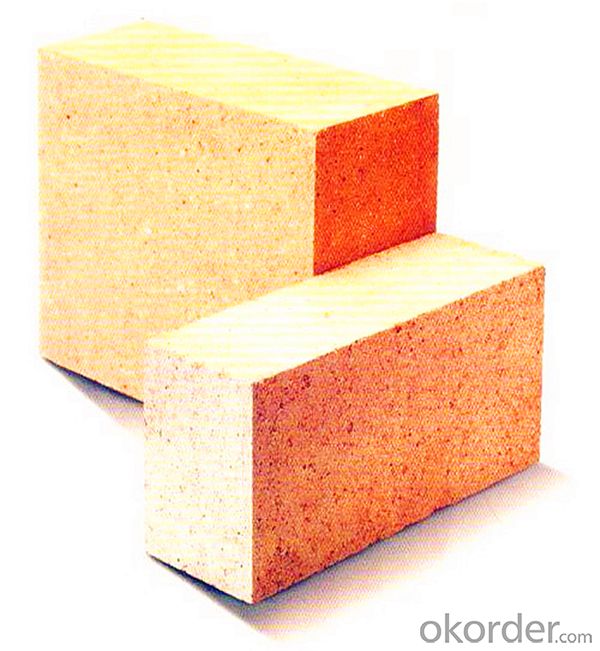

Major Images

Refractory High Alumium and Fireclay Brick

Specification for High Aluminum Refractory Brick

ITEM | UAL48 | UAL55 | UAL65 | UAL75 | UAL80 | UAL85 | ALP80 |

Refractoriness, ℃ | 1750 | 1770 | 1790 | 1790 | 1810 | 1810 | 1810 |

Apparent Porosity,% | 22 | 22 | 23 | 23 | 20 | 20 | 18 |

C.C.S, Mpa | 39 | 44 | 49 | 53 | 55 | 60 | 100 |

Refractories Under Load (0.2Mpa),℃ | 1420 | 1470 | 1500 | 1520 | 1500 | 1520 | 1550 |

Reheating Linear Change,% | 1450x2h 0.1~-0.4 | 1500x2h 0.1~-0.4 | 1500x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1550x2h -0.5~+0.5 | 1550x2h -0.5~+0.5 | 1550x2h -0.5~+0.5 |

Al2O3 Content , % | 48 | 55 | 65 | 75 | 80 | 85 | 82 |

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories, at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time, seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed, when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

- Q: What is fireproof concrete?

- According to the different properties of fire resisting and heat resisting concrete, they can be divided into silicate, aluminate, phosphate, sulfate, chloride, sol and organic substance, fireproof and heat-resisting concrete, etc.. The following are mainly used silicate, aluminate, phosphate, sulfate fire, heat-resistant concrete.

- Q: What are the high aluminum bricks made of?

- The amount of refractory mud accounts for about 6% of the brick weight

- Q: How much is one ton of high alumina refractory brick?

- Three high aluminum refractory brick Zhengzhou Kuwait is generally around 800. 32 years of experience, good.

- Q: What's the difference between high alumina refractory bricks and high alumina refractory bricks?

- High alumina refractory brick in all thermal shock properties except performance are better than clay refractory brick, masonry in furnace and thermal equipment, such as clay bricks can be competent the work environment is not high aluminum brick masonry.

- Q: What is the density of a super high alumina brick and what is the price?

- Of course, the transaction price, please choose refractory brick manufacturer is better.

- Q: Can high alumina brick resist carburizing?

- It is heavy brick mullite brick, brick to do the heavy weight to more than 2.4 manufacturers can achieve a few feeling

- Q: What is the difference between high alumina brick and clay brick?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color. For example: 75 high aluminum and 43 clay bricks, 75 single weight 4.5kg or more. 43 3.65kg or so, the use of temperature 75, high aluminum in about 1520, 43 of brick 1430 or so, the color of 75 pan white, 43 of the Loess color. In short, the difference is great.

- Q: How high can aluminum bricks expand at 80O degrees of heat?

- When an object is heated, the particle moves faster and thus occupies additional space. This phenomenon is called dilation.

- Q: What is the high temperature limit of refractory bricks and refractory soil?

- Fire clay -- usually refers to folk point stove furnace set with a kind of soil, limit under atmospheric pressure of 1500 degrees fire clay soil 1, properties and uses: clay brick of weak acid refractory material, its thermal stability is good, suitable for hot blast furnace, boiler and flue, smoke chamber lining, etc..2, product specifications form: standard shape, general, special-shaped and special-shaped brick. Physical and chemical properties of fireclay bricks.

- Q: What should be used as binder for making high alumina bricks?

- Bond for making high alumina brick: soft clay has good plasticity, so the high alumina brick is usually made of soft clay as bond. However, the free Al2O3 free SiO2 and bauxite clinker clay in under 1200 degrees occurred two times of Mullization reaction, generate large volume expansion, silicon porosity, strength reduction. Therefore, the amount of clay powder in the ingredient should be no more than 5%.

Send your message to us

High Alumina Brick for High Strength Glass Kiln Thermal Insulating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1044 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords