HDPE Blow Molding Grade

- Loading Port:

- Guangzhou Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- 120000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

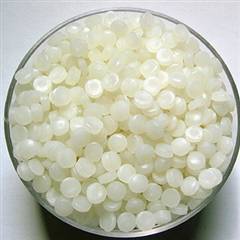

HDPE--Blow Molding Grade:

HDPE film grade has excellent physical properties, good process ability, high mechanical strength and good stain ability, printability and salability. The resin is resistant to moisture, oil and chemical corrosion and has excellent high-speed processing properties.

Applications of HDPE Blow Molding Grade:

HDPE film grade is widely used in the production of T-shirt bags, shopping bags, food bags, garbage bags, packaging bags, industrial lining and multilayer film. In recent years, the resin has been increasingly used in beverage and medicine packaging, hot filling packaging and fresh produce packaging. The resin can also be used in the production of anti-seepage film used in hydraulic engineering.

Package, Storage and Transportation of HDPE Blow Molding Grade:

The resin is packaged in internally film-coated polypropylene woven bags, brown paper bags or laminated polyethylene film bas. The net weight is 25Kg/bag.

The resin should be stored in a drafty, dry warehouse and away from fire and direct sunlight. It should not be piled up in the open air During transportation, the material should not be exposed to strong sunlight or rain and should not be transported together with sand, soil, scrap metal, coal or glass. Transportation together with Toxic, corrosive and flammable substance is strictly prohibited.

Grades and Typical Values (Not Warranted Values):

Grades | 6098 | 6000F | 7000F | 7700F | |

MFR | g/10min | 11.0 | 0.53 | 0.23 | 0.3 |

Density | g/cm3 | 0.95 | 0.953 | 0.951 | 0.951 |

Tensile Strength | Mpa≥ | 23 | 23 | 24 | 23 |

Elongation at break | %≥ | 600 | --- | 55 | 600 |

Fish eyes,pcs/1520cm2 | 0.8mm/1520cm2 | 2.0 | --- | 1.5 | 2.0 |

0.4mm/1520cm2 | 15 | --- | 15 | 20 | |

Grades | MH602 | TR130 | TR142 | TR144 | |

MFR | g/10min | 6.0 | 0.28 | 0.26 | 0.19 |

Density | g/cm3 | 0.946 | 0.938 | 0.946 | 0.946 |

Tensile Strength at yield | MD ≥ Mpa | 48 | 21 | 26 | 26 |

MD% ≥ | 37 | 21 | 25 | 25 | |

Elongation at break | MD %≥ | 280 | 600 | 600 | 600 |

TD%≥ | 240 | 500 | 500 | 500 | |

Tearing Strength | MD N≥ | 0.08 | 50 | 26 | 26 |

TD N≥ | 0.4 | 500 | 410 | 410 | |

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1953 |

| Annual Output Value | Above US$ 250 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port, China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

HDPE Blow Molding Grade

- Loading Port:

- Guangzhou Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- 120000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords