India Gypsum Ceiling PVC Laminated 576

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plasterboard is made of high-grade environmental protective gypsum raw material, no harming to human body, and it has some performances: (such as environmental protection, fire-proof, moisture-proof, light and high intensity).

Plasterboard is easy to install, and its decoration effect is good. Its special indoor temperature adjustment function can provide a comfortable living environment. It is the first choice to interior decoration.

Plasterboard is made of high-grade environmental protective gypsum raw material, no harming to human body, and it has some performances: (such as environmental protection, fire-proof, moisture-proof, light and high intensity).

Product Applications:

+ Furred ceiling

+ Interior wall cover

+ Partition wall

1.Thermal insulation

2.Fire-resistant performance for fire-proof plasterboard

3.Water-resistant performance for water-proof plasterboard

4.Easy installation (it can be easily sawed,planed,holed and sticked)

5.Special respiratory function (it has a great mass of ting holes

Product Advantages:

1.Thermal insulation

2.Fire-resistant performance for fire-proof plasterboard

3.Water-resistant performance for water-proof plasterboard

4.Easy installation (it can be easily sawed,planed,holed and sticked)

5.Special respiratory function (it has a great mass of ting holes and its function of moisture-adsorbing and moisture-dismissing)

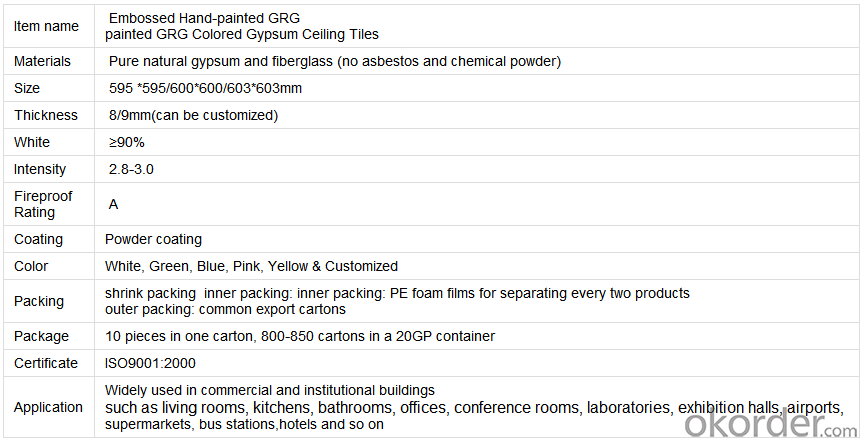

Main Product Features:

Material: Gypsum Board, non asbestos, sulfate free

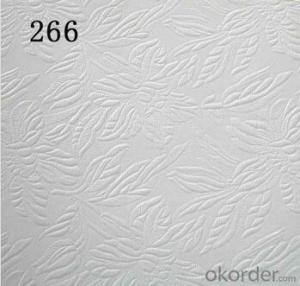

Surface: High quality PVC/Vinyl

Backside: High quality aluminized PET foil

Edges: Square

Weight /cbm: 780kgs/m3

Tolerance: Length: ± 1.0mm, Width: ± 1.0mm,

Thickness: ± 0.5mm

NRC: 0.1 - 0.3

Light reflection: 0.75

Standards: Gypsum boards are manufactured according to EN-520, ASTM C1396, E84 and E96

Humidity resistance: up to 95% relative

Product Specifications:

FAQ:

1. What kind of certificate do you have?

ISO9001, ISO14001, CE, SONCAP, VOI(CO), CARB, FSC, CE

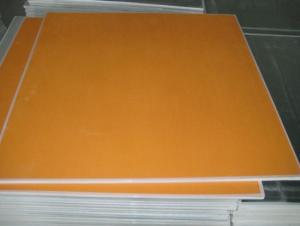

2. What color can you produce?

You can choose the design you want

3. How about the delivery time?

20-25 days after receiving prepayment or L/C

For the samples, it will be prepared ASAP.

4. What's the MOQ and Payment Terms?

Minimum Ordering Quantity: 2X20ft Container

Payment Terms: T/T or L/C at sight

Images:

- Q: Did the screw punch break the ceiling gypsum?

- Split, the above is a small piece of a small box, the grid can be pushed up, pushed open, the line, the installation. Place a small board on the ceiling of the camera's mounting position, and the camera fixing screw is screwed onto the board.

- Q: Gypsum line how much money one meter? What is the standard size of gypsum line?

- Gypsum line mainly include: angle, flat line, arc and so on. The main raw material for the gypsum powder is mainly installed in the ceiling and the angle between the ceiling and the wall, which can be through the water pipe and so on, practical and beautiful, low price, with fire, moisture, insulation, noise, insulation, and can play luxury The decorative effect. Gypsum line length is generally 2.5 m / root, the width is generally 8 cm to 15 cm. There are shadows small size 3 cm ---- 5 cm, flat minimum 3 cm, gypsum line now there are several, the most common size 20mm * 80mm * 3m, the price of two one meter, European, on the 120 -200 height has.

- Q: what is jointless gypsum ceiling??what are the other terms used for it?

- Primarily used in Europe, Jointless gypsum ceilings refer to installing a sheathing type gypsum board over an existing framing platform then installing panels usually plastic over the gypsum using a beaded plastic T molding that installs into the joints of the unfinished gyp board. Pain in the butt, not very desirable to the Americans historically. But, products may have changed since the last time I seen it. GL

- Q: I would like to ask: light steel keel gypsum board ceiling materials and labor costs are how much money?

- Light steel keel material fee is not good to say, GB, non-standard, too much. Big to say it, the main vice keel hanging pieces per square in about 40, gypsum board and accessories 10 yuan, about 50 yuan per square. Labor costs, flat top 30 or so. Modeling top 50 or so. In the complex top to see the drawings to price.

- Q: Bathroom waterproof gypsum board ceiling price how much

- Material cheaper 2o each with keel, etc., but the high cost.

- Q: Gypsum board stacked ceiling What does it mean?

- L-type is a simple straight or back to the type of ceiling, suitable for simple decoration style. Gypsum board straight ceiling ceiling is usually 600 * 600, with a protruding pattern, with 38 main bone and T bone assembly.

- Q: Detailed construction technology

- This you have to do more dynamic technology can ah, or certainly not work!

- Q: How to hollow ceiling production?

- Ceiling design, also known as smallpox design, ceiling design, is to use some elegant materials and lighting to the bare ceiling "package" up. Ceiling generally have flat ceiling, shaped ceiling, local ceiling, grille ceiling, algae-type ceiling, and other five types. Flat ceiling is generally made of PVC board, aluminum gusset plate, gypsum board, mineral wool sound-absorbing panels, glass fiberboard, glass and other materials, lighting lying in the top of the plane or suck on the top, due to the general arrangement of the room in the bathroom, , Balcony and entrance and other parts.

- Q: 16 square meters living room to do gypsum board around the ceiling about how much money

- Probably need 4 gypsum board, 8 bundles of keel, plus nails and other small pieces of accessories, about 500 yuan can be, no fee

- Q: What kind of material is the interior of the ceiling?

- Indoor ceiling lines close a lot of material. More common are: gypsum lines, solid wood lines, high-density bubble line, stainless steel lines, glass lines, etc. This line can be arbitrarily modified processing, different materials can be made not the same effect.

Send your message to us

India Gypsum Ceiling PVC Laminated 576

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords