Composite Pipes GRP FRP Equal Tees Sea Water Pipe Series DN 50-200

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features & Benefits of GRP FRP Equal Tees Sea Water Pipe Series

Corrosion-resistant

•Long, effective service-life materials

•No need for linings, coatings, cathodic protection, wraps or other forms of corrosion protection

•Low maintenance costs

•Hydraulic characteristics essentially constant over time

Light weight

(1/4 weight of ductile iron; 1/10 weight of concrete)

•Low transport costs (nestable)

•Eliminates need for expensive pipe handling equipment

Long standard lengths

(6, 12 metres)

•Fewer joints reduce installation time

•More pipe per transport vehicle means lower delivery costs

Extremely smooth bore

•Low friction loss means less pumping energy needed and lower operating costs

•Minimum slime build-up can help lower cleaning costs

Precision sealability

With elastomeric rubber rings

•Tight, efficient joints designed for bell & spigot to eliminate infiltration and ex-filtration

•Ease of joining, reducing installation time

• Accommodates small changes in line direction without fittings or differential settlement

Flexible manufacturing

•Custom diameters can be process manufactured to provide maximum flow volumes with ease of installation for rehabilitation

lining projects

High technology pipe design

•Lower wave celerity than other piping materials can mean less cost when designing for surge and water hammer pressures

High technology pipe manufacturing system producing pipe that complies to stringent performance standards (AWWA, ASTM, DIN, EN, etc.)

•High and consistent product quality worldwide which ensures reliable product performance

Control Testing of GRP FRP Equal Tees Sea Water Pipe Series

Raw Materials

Raw materials are delivered with vendor certification demonstrating their compliance with Zhongfu Lianzhong quality requirements. In addition, all raw materials are sample tested prior to their use. These tests ensure that the pipe materials comply with the specifications as stated

Physical Properties

The manufactured pipe’s hoop and axial load capacities are verified on a routine basis. In addition, pipe construction and composition are confirmed.

Finished Pipe

All pipes are subjected to the following control checks:

• Visual inspection

• Barcol hardness

• Wall thickness

• Section length

• Diameter

• Hydrostatic leak tightness test to 1.5 rated pressure (only PN6 and above)

On a sampling basis, the following control checks are performed:

• Pipe stiffness

• Deflection without damage or structural failure

• Axial and circumferential tensile load capacity

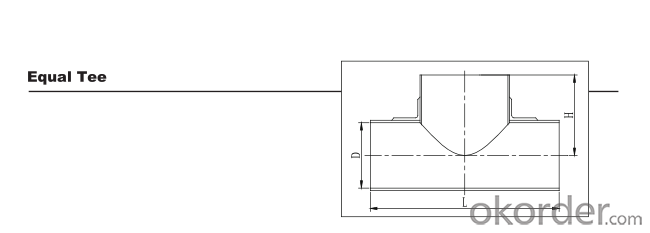

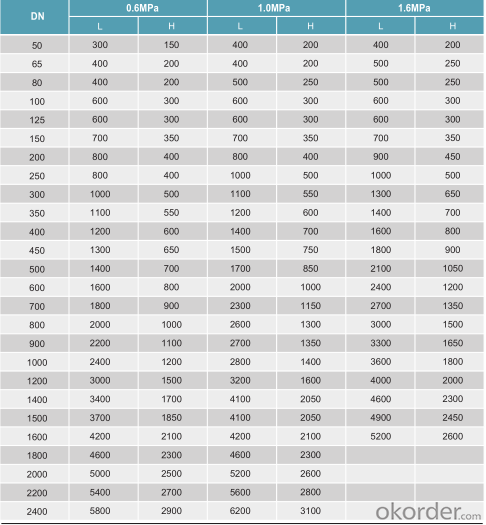

Model of GRP FRP Equal Tees Sea Water Pipe Series

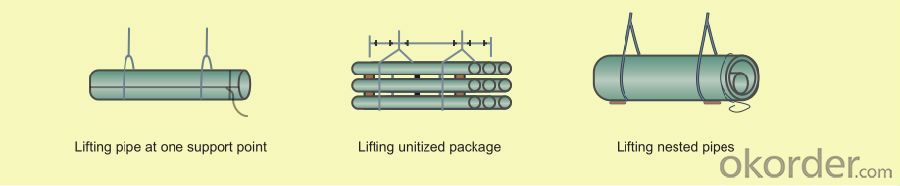

Unloading,Handling,Transportation and Storage of GRP FRP Equal Tees Sea Water Pipe Series

Unloading the pipe is the responsibility of the customer. Be sure to maintain control of the pipe during unloading. Guide ropes attached to pipes or packages will enable easy manual control when lifting and handling. Do not drop, impact, or bump the pipe, particularly at pipe ends.

If at any time during handling or installation of the pipe, any damage such as a gouge, crack or facture occurs, the pipe should be repaired before the section is installed.

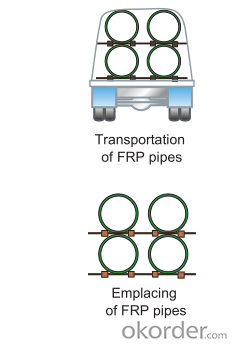

Transporting Pipes

Strap pipe to the vehicle over the support points using pliable straps or rope. Never use steel cables or chains without adequate padding to protect the pipe from abrasion. Bulges, flat areas or other abrupt changes of curvature are not permitted. Transport of pipes outside of these limitations may result in damage to the pipes.

Site Pipe Storage

It is generally advantageous to store pipe on flat timber to facilitate placement and removal of lifting slings

around the pipe.

When storing pipe directly on the ground, be sure that the area is relatively flat and free of rocks and other

potentially damaging debris. Placing the pipe on mounds of backfill material has been found to be an effective

way of site storing the pipe. All pipes should be chocked to prevent rolling in high winds.

FAQ of GRP FRP Equal Tees Sea Water Pipe Series

Q1: What’s the performance standards?

Lianzhong pipe is designed to meet all of these ASTM , AWWA, BS, DIN standards.

Q2: What’s the qualification testing for the products?

Lianzhong pipe has been rigorously tested to verify conformance to the ASTM D3262, ASTM D3517, AWWA C950 and DIN 16868 requirements

Q3: How long can I receive my goods?

A: Usually, we will deliver products within 20 days after the contract is signed. Delivery time is negotiable when necessary.

- Q: Designed to support FRP pipes, is it m or mm?

- Glass fiber reinforced plastic cable protection tube chemical composition: GRP winding pipe is a kind of glass fiber reinforced plastic product. With the continuous development of glass fiber reinforced plastic molding technology, FRP products have been widely used in various fields. FRP products have the advantages of light quality, high strength, corrosion resistance, long service life, flame retardant, high temperature resistance and various forms of products. Therefore, the industry gradually increase the use of glass fiber reinforced plastic products, which will be reinforced FRP mechanical properties and molding process put forward higher requirements. The forming process of FRP determines its shape, property and application prospect. The mechanical properties of glass fiber reinforced plastics determine whether their products can be widely used in industries with higher mechanical properties. Fiberglass reinforced plastic square tubes can replace some metal pipes used in industrial and civil fields, such as central air conditioning, chemical plants, etc. but glass fiber reinforced plastic square tube products are not common in the market. This is mainly due to the existence of poor strength, easy deformation and other defects.

- Q: FRP pipe and 0.7 thick galvanized pipe which cost is low?

- The best material in glass steel mould rubber production 20 years, customers in all aspects

- Q: What are the standards for FRP pipes?

- In order to comprehensively check the installation quality of the pipeline, it is necessary to carry out a comprehensive examination according to the test methods stipulated in the code for construction and acceptance of water supply and drainage pipeline works and to carry out the water pressure test. Permissible water seepage can be carried out according to the standard of FRP pipe.

- Q: What are the disadvantages of glass fiber reinforced sand pipe?

- Glass reinforced plastic sand pipe is mainly to increase the rigidity of the pipe, the relative wall thickness of pure glass steel tube, low compressive strength, shock resistance decreased.

- Q: What can be done to solve the leakage of FRP pipe?

- DN1800 FRP pipe pressure of 9 kilograms, the pressure is very high, crushed by stones, not repaired will certainly leak, the pressure pipe leakage is very bad, will be washed away the soil, spewing a few meters high water column.

- Q: What is the difference between glass tube, sand pipe and glass tube?

- The pipeline in the design according to the use of pressure, stiffness and other conditions to determine the need for sand, if the thickness of the pipe can satisfy the pressure requirements and can meet the requirement of stiffness, is generally not the sand.

- Q: Are there any differences between FRP pipes and FRP pipes?

- The mechanism glass magnesium composite pipe is made of glass cloth, magnesium and earth, which is hard to burn. The glass fiber reinforced plastic pipe is made of glass cloth and resin, and it is inflammable and light in weight.

- Q: What epoxy resin is used for anticorrosion of pipeline glass fiber reinforced plastics?

- 3PE has some disadvantages. (1) the bending of the guiding hole and the protruding rock, pebble and gravel in the hole will cause friction and scratch to the relatively soft 3PE corrosion resistant layer. (2) 3PE coating using polyethylene heat shrinkable sleeve joint, the convex part of the concave or lap joint, which makes it easy to travel being scratched or pulled off lead. (2) 3PE corrosion protection layer has a strong electrical shielding, so that the cathodic protection current is difficult to reach the defects of corrosion protection layer, thus causing perforation corrosion.So, from the last century at the beginning of 90s, the United States developed Powercrete (s) Powder Concrete Anticorrosion structure, namely in the bottom of fusion bonded epoxy powder, sprayed with epoxy resin as main film-forming material, and adding a two-component epoxy coating for concrete, polymer concrete curing agent and other inorganic fillers. The coating is tough and wearable and can be used directly in FBE coated pipes to protect the pipe from damage during handling, directional drilling, crossing, etc..

- Q: Uneven settlement of the foundation, can lead to glass fiber reinforced plastic underground water pipes burst, what is the principle?

- Can cause rupture. FRP material originally resistant to pressure better, tensile, shear resistance is poor, the foundation sinking is shear, I want to sink more than 5 cm, if the soil around the pipeline is compacted, it may break

- Q: How long is the service life of glass fiber reinforced plastic pipes?

- Glass fiber reinforced plastic grille can reduce power consumption and simplify management. Galvanized grille plate adopts high efficiency and low resistance water collecting device, floating water rate is less than 0.001%, environmental protection is the best. The galvanized grating plate has the advantages of advanced structural design, optimum matching of gas and water, and sufficient heat exchange, with the same level in foreign countries and superior output. The company has a realistic, innovative research team. The galvanized grille fan adopts a tensile type of strong wind blade and long space, which is more stable when the fan is running, thereby reducing noise and greatly improving the cooling efficiency. Successively in Shanghai, Guangdong, long-term and domestic famous universities, research institutes cooperation. Hebei, Qingdao and Beijing have additional production bases and service liaison points. Willing to work with new and old customers to create a beautiful today, Chinese and foreign.

Send your message to us

Composite Pipes GRP FRP Equal Tees Sea Water Pipe Series DN 50-200

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords