Composite Glass Reinforced Epoxy (GRE) Pipe for Brine Water Pipelines

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m

- Supply Capability:

- 200000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GRE Pipe Description

GRE pipe is short for Glass Reinforced Epoxy pipe.

Generally high pressure FRP pipe, mainly used in oil field oil, water, polymer injection pipelines, natural gas transportation, urban drainage, drinking water pipelines, chemical industry, brine pipeline, fire pipelines and other fields.

Main Application:

1. Pipeline of brine, water and crude oil

2. Pipeline of polymer solution

3. Collection pipeline of crude oil and natural gas

4. Oilfield sewage, chemical sewage and waste water disposal pipe

5. Water distribution system

6. Petrochemical technical pipeline

Main Features of the GRE Pipe

1. High physical-mechanical character

2. High corrosion-resistant capability

3. Excellent heat-Rsistant capability; the mormal working temperature is 80 degree, which can meet the requirement of technology of oil extraction and effusion.

4. High-pressure-resistant capability: normal operating pressure grade from 3.5MPa to 25MPa.

5. Light weight

6. Long life, the designed service life is not shorter than 20 years.

7. High flow property of medium, non scaling, non depositing wax, will not being clogged.

8. Screw threaded connections and convenient installation.

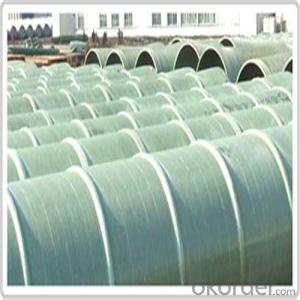

GRE Pipe Images

GRE Pipe Specification

1.Diameter:1.5inches(38mm)--24inches(600mm)

2.Pressure Grade:3.5---25MPa

3. Production Length: 9m or 11.8m

4. Connection Methods: API screw thread seal with aquaseal connection of eight rounds or ten rounds

FAQ of GRE Pipe

Q: What are the basic characteristics of the glass tube

Excellent physical and mechanical properties

Density fiberglass pipe is usually 1.8-2.1g / cm3, about 1/4 of steel, are higher than that of steel, cast iron and plastic than strength. The weight of the glass tube is generally greater than the same size steel 1/3 superior physical and mechanical properties; in addition, the thermal expansion coefficient of the glass tube and steel roughly, only 0.5% of the thermal conductivity of steel, is a good thermal and electrical insulation material.

Q: Is GRE Pipe chemical resistant with a long life?

GRE pipe has a special resistance to chemical corrosion in pipes criss-cross, dotted down environment, you can choose a different corrosion-resistant pipes according to the requirements of the medium.

Q: How are the hydraulic properties?

Water is one of the important mechanical properties of glass pipe. Hydraulic fluid excellent characteristics mean little head loss, you can use a smaller diameter or smaller power pump, thereby reducing the initial investment pipeline projects, save energy, reduce operating costs.

- Q: FRP pipe and 0.7 thick galvanized pipe which cost is low?

- Glass steel pipeline, FRP pipe and 0.7 galvanized steel pipe glass steel pipes cost is obviously low, FRP pipe material factory manufacturing costs and labor costs are relatively low, the price is only about the same thickness of galvanized pipe 60-70%, I hope you can help!

- Q: Mending method for glass fiber reinforced plastic pipe

- Other repair methods: choose resin, accelerator, curing agent, high quality glass fiber cloth. Don't let the powder go. It is autumn, the temperature is low, so to put more than summer curing agent, the proportion of the curing agent, accelerator, resin; 1:1.5:8 with glass fiber wrapped around the pipe, coated on the glass fiber cloth for glass steel with a good quick, let the glass steel glass fiber cloth fully soaked, waiting for glass steel fully cured, and then repeated several layers. It will be strong.

- Q: Which is better, PVC pipe and GRP pipe?!

- Of course, FRP pipe, high strength, aging resistance, PVC too crisp

- Q: How to open a DN300 port on the DN600 GRP pipe and install the DN300 gate?!

- Do not know the road of glass steel flange have, if any to buy different materials of cast iron flanges or PVCU flange on the same material, the three way behind the pipeline branch, so that the material market has purchased (ABS buy buy in the small town is not easy), the construction is convenient. If it is a glass steel pipe, pipe end cannot change, can only be used to bond the glass steel material, the pipe bonded on the flange is an arc for a plane is bonded with a cast iron pipe flange suggestions. Because the FRP material and most of the plastic are not bonded.

- Q: What's the difference between glass fiber reinforced plastic pipe and glass fiber reinforced sand pipe?

- Glass reinforced plastic sand pipe is actually in the production of glass fiber reinforced plastic pipe, in the middle to increase a layer of sand layer, the purpose is to increase the rigidity of the pipeline. The pipeline in the design according to the use of pressure, stiffness and other conditions to determine the need for sand, if the thickness of the pipe can satisfy the pressure requirements and can meet the requirement of stiffness, is generally not the sand.

- Q: Is it possible to touch the water when the glass fiber reinforced plastic pipe is polished?

- For nearly 20 years of brand silicone mold manufacturers, steel and glass also played nearly 20 years, glass steel pipe interface after grinding with water is Never mind, can be polished with water to the point where you can proceed to the next step of the operation of the glass steel bonding with a clean cotton cloth to wipe clean.

- Q: Are there any differences between FRP pipes and FRP pipes?

- The mechanism glass magnesium composite pipe is made of glass cloth, magnesium and earth, which is hard to burn. The glass fiber reinforced plastic pipe is made of glass cloth and resin, and it is inflammable and light in weight.

- Q: How to prevent the glass fiber reinforced plastic pipe from being damaged by aging or over pressure, causing the liquid to splash and hurt people

- If you are afraid of the glass tube will be such a question, the weak links or parts of the local reinforcement, the conditions can, can re pipe liner, to compression, anti ageing effect

- Q: What are FRP pipes used for making? What raw materials?

- The glass tube with its unique strong corrosion resistance, smooth surface materials, low energy consumption and long service life (50 years), convenient transportation and installation, maintenance and many other advantages of low cost and low cost in electric power, petroleum, chemical industry, papermaking, city water supply and drainage, sewage treatment plant, seawater desalination, gas transportation other industries have been widely applied.

- Q: How long is the service life of glass fiber reinforced plastic pipes?

- Glass fiber reinforced plastic grille can reduce power consumption and simplify management. Galvanized grille plate adopts high efficiency and low resistance water collecting device, floating water rate is less than 0.001%, environmental protection is the best. The galvanized grating plate has the advantages of advanced structural design, optimum matching of gas and water, and sufficient heat exchange, with the same level in foreign countries and superior output. The company has a realistic, innovative research team. The galvanized grille fan adopts a tensile type of strong wind blade and long space, which is more stable when the fan is running, thereby reducing noise and greatly improving the cooling efficiency. Successively in Shanghai, Guangdong, long-term and domestic famous universities, research institutes cooperation. Hebei, Qingdao and Beijing have additional production bases and service liaison points. Willing to work with new and old customers to create a beautiful today, Chinese and foreign.

Send your message to us

Composite Glass Reinforced Epoxy (GRE) Pipe for Brine Water Pipelines

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m

- Supply Capability:

- 200000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords