Globond Plus PVDF Solid Aluminium Panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GLOBOND Plus PVDF Solid Aluminium Panel

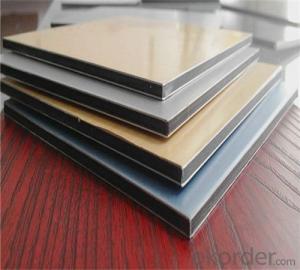

GLOBOND plus PVDF solid aluminium panel is made from excellent aluminium alloy plate, with PVDF painting of PPG or Akzo coated on the surface. The whole process of production adopts advanced NC panel beating device, NC multifunctional forming punch and the latest “Ransburgi” automatic electrostatic spray unit from Japan. Standard thickness:2.0㎜,2.5㎜,3.0㎜etc.

Product Structure

GLOBOND plus PVDF solid aluminium panel mainly consists of face plate, stiffening rib and hangers. If necessary, the back of the panel may fill in heat-insulation ore cotton. The hangers can be made by curving the face plate directly, or installed separately by aluminium profile. In order to ensure the flatness of the panel for long-term use, we install the stiffening rib on the back of face plate by bolts, to make it as a firm integral unit, thus enhancing the strength and rigidity of the material.

Application

Curtain wall of buildings, pillar, balcony, partition board, interior decoration, billboard, vehicle, furniture, exhibition booth, instrument enclosure, subway station, shipping vehicle ect.

Feature

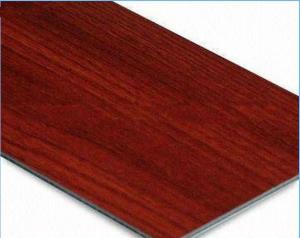

1. Good formability, it can be formed to plane, arc, and complicated shape such as sphere and tower.

2. Hard to stain, easy to clean and maintain

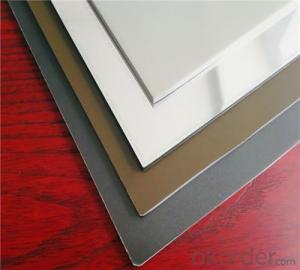

3. Wide range of colors optional, excellent decoration effect

4. Easy to recycle, no pollution

- Q: I have thousands of pounds of aluminum slab scrap where the acquisition, how much money a kilogram

- Then you sell seven yuan it

- Q: What are the characteristics and uses of aluminum-plastic panels?

- It can be used in the renovation of old buildings, as the counter, the surface of the furniture, the inner and outer walls of the vehicle, and so on. It can also be used in the decoration of the old building, such as the curtain wall, the inner wall, the foyer, the hotel, the store and the conference room.

- Q: I want to open a small aluminum-plastic plate factory, how much money

- The current factory feel awkward to find a small factory OEM, just now, the industry situation is the lack of rice is not the lack of pot cooking utensils, no customers and orders the most trouble friends.

- Q: Will the aluminum plate can make a wardrobe?

- can

- Q: Does the production process produce toxic substances? What is the impact on the body? Does the production of coated aluminum also produce toxic substances?

- Dust hazards Aluminum plants in the production process of dust mainly aluminum oxide dust, petroleum coke dust, asphalt dust. Alumina dust mainly exists in the electrolytic plant, the alumina storage and transportation system; the calcining section of the feeding system, nesting system, calcined after the section of the kneading machine, preheating screw machine and milling system dust and asphalt smoke; There are asphalt smoke generated; residual processing section of the coarse crushing, ingredients, screening and other processes are dust generated. Crane driver, electrolysis workshop workers, carbon powder broken, screening and other workers by the dust hazard. According to TJ36-79 "industrial enterprise design health standards" provides that the workshop the maximum allowable concentration of harmful substances in the air, the dust in the production of alumina dust should not exceed 6mg / m3; other dust (when the free silica content of 10% ) Shall not exceed 10mg / m3.

- Q: What is the current market price of aluminum veneer and aluminum plate?

- Currently on the market price of aluminum-plastic plate, here only speak facade curtain wall, 200 yuan or so. Simple material prices.

- Q: Is there a good separation,

- Ethanol acetone heat treatment, stripping.

- Q: On the report of the project price per square meter engineering requirements is to use 50 * 5 angle iron keel with 4mmA grade aluminum-plastic plate dry hanging

- Skeleton anchors should be made with embedded parts, in the absence of embedded parts in the case of post-embedded parts, embedded parts of the structural form to meet the design requirements, before the construction according to the project axis and the center line and the baseline level Embedded parts to check and check, the general allowable position size deviation of ± 20mm. Bolt to be carried out on-site drawing test to meet the strength requirements before use. If the location of embedded parts can not be used or leakage, should be based on the actual situation of the expansion bolts fixed post-embedded embedded parts of the program, and must be reported to the design unit approval, and should be done in the field pull test, Take good notes. The anchors are usually made up of buried plates and connecting corners, which are accurately marked on the centerline of the mullion, and then the holes are fixed and the centerline of the mullion leads to 0.8 Mm wire (both ends with the basket screw tightening) for signs control line. And then the level of the standard and the standard steel embedded parts, and then calculate the location of the connection angle code, in the buried plate on the crossed mark, the same mullion connected to the same side of the corner position to pull the line detection, can not be biased. Corner position to determine, the corner code according to this location welding to the buried floor, the width and length of the weld to meet the design requirements, welding after welding to do rust treatment, the general brushing antirust paint twice.

- Q: Curtain wall sun room stone hit glass hit wood carpentry workers

- Do the most suitable for glass glue I did such a project maintenance

- Q: Silver aluminum plate is what material is not silver aluminum plate?

- According to the current building facade commonly used materials to judge, it should be said that aluminum is a class, either aluminum or plastic plate, or according to the pronunciation, it should be said that there may be aluminum veneer. There is something close to carbon.

Send your message to us

Globond Plus PVDF Solid Aluminium Panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords