Glass Fiber and Ceramic Fiber Textiles for Refractory Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | (Mainland) | Application: | Refractory | Model Number: | LBR11110904 |

| Brand Name: | Color: | pure white | Working Temperature: | 1100-1350 | |

| Grade: | ST(STANDARD) | Length: | 30000mm | Density: | 500kg/m3 |

| Width: | 10-150mm | Thickness: | 2-10mm | Fiber diameter: | 3um |

Packaging & Delivery

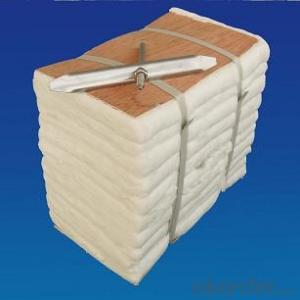

| Packaging Detail: | Wrapped by plastic bag inside,protected by carton box outside. |

| Delivery Detail: | 15 days after deposit |

Specifications

Ceramic Fiber Tape:

1.Glass-fiber reinforced;

2.Environmental-Friendly;

3.Easy to use;

4.Harmless to human.

Characteristics

Good compression strength.

Non-toxicity, environmental protection.

Low thermal conductivity and low thermal capacity.

Good antacid oil resistance and water vapor resistance.

Ceramic Fiber Textile

The Product Description

Ceramic fiber textile includes Ceramic fiber cloth, strap, twisted rope,

round straided rope and square straided rope.All are made from our high quality

ceramic fiber material. They can be used for high temperature applications up to

2300°F. The rope is reinforced with fiberglass filament, and optional Inconel/alloy

steel wire. Ceramic fiber textiles (cloth, tape and rope) contain a certain amount

of binder material which is normally burned at lower temperature and does not affect

the insulation property.

The three different styles are designed to fit different application needs: twisted rope

is a soft rope, while square and round braid are more dense .

Application

Common applications :door seals or caulking for ovens, furnaces and boilers,

expansion joints, cable or pipe wrapping, high temperature seals or gaskets.

widely used in welding, foundry works, aluminum and steel mills, boiler insulation

and seal, exhaust systems, shipyards, refineries, power plants and chemical plants.

We also provide many other refractory and insulation materials, so if you have demands

about them, pls contact us.

Technical data

Item | Cloth | Tape | Round rope | Square rope | Twisted Rope(Yarn) | Twisted rope(wool top) |

Classification Temp °C | 1260 | |||||

Bulk Density kg/m3 | 500±30 | |||||

Organic Content | ≤15 | |||||

Working Temp | 450(Glassfiber Filament) | |||||

1000(Metal Wire ) | ||||||

Loss After Firing(800°C)% | 12±2 | 12±2 | 12±2 | 12±2 | 12±2 | 8-10 |

Size | 30mx1mx2 30mx1mx3 | widen10-120mm length30m | Φ6-50mm

| 20x20 | Φ6-50mm

| Φ6-50mm

|

Any question,pls feel to contact us!

- Q: How are glass fiber textiles used in the sports industry?

- Glass fiber textiles are commonly used in the sports industry for various applications. They are used to reinforce sporting equipment such as tennis rackets, hockey sticks, and golf clubs, making them stronger and more durable. Glass fiber textiles are also used in the production of sports clothing and footwear to enhance their strength, flexibility, and breathability. Additionally, these textiles are used in the construction of sports facilities like stadiums and arenas, providing structural strength and resilience. Overall, glass fiber textiles play a crucial role in improving performance, safety, and quality in the sports industry.

- Q: Can glass fiber textiles be used in air ducts?

- Yes, glass fiber textiles can be used in air ducts. Glass fiber textiles are commonly used as insulation materials in HVAC systems, including air ducts. They have excellent thermal properties, providing insulation to prevent heat transfer and maintain the desired temperature inside the ducts. Glass fiber textiles are also resistant to moisture, mold, and mildew, making them ideal for use in environments with high humidity levels. Additionally, they are lightweight and easy to install, making them a practical choice for air ducts. Overall, glass fiber textiles are a suitable option for insulating and protecting air ducts in various HVAC applications.

- Q: Are glass fiber textiles fire resistant?

- Yes, glass fiber textiles are generally fire resistant. Glass fiber is made from molten glass that is spun into thin fibers, which are then woven or knitted to create textiles. These textiles have a high melting point and do not ignite easily when exposed to heat or flame. Additionally, glass fiber textiles have low thermal conductivity, meaning they do not conduct heat well, further reducing the risk of fire spreading. They are commonly used in applications where fire resistance is important, such as in protective clothing, curtains, and insulation materials. However, it is important to note that while glass fiber textiles are fire resistant, they are not completely fireproof and can still be damaged or destroyed by intense heat or prolonged exposure to flames.

- Q: What is the cost of glass fiber textiles compared to other materials?

- The cost of glass fiber textiles is generally lower compared to other materials such as carbon fiber or Kevlar. However, it can vary depending on the specific application and quality of the material.

- Q: Can glass fiber textiles be used in conveyor belts?

- Certainly! Conveyor belts can make use of glass fiber textiles. Glass fiber textiles possess remarkable attributes such as exceptional heat resistance, chemical resistance, and resistance to abrasion, which endow them with high strength. Therefore, they are well-suited for a range of industrial uses, including conveyor belts. By incorporating glass fiber textiles as reinforcement materials, conveyor belts can experience heightened durability and tensile strength. Furthermore, glass fiber textiles excel in providing effective thermal insulation, rendering them suitable for conveyor belts operating in environments with high temperatures. In conclusion, glass fiber textiles present a multitude of benefits that establish them as a feasible choice for integration into conveyor belts.

- Q: Can glass fiber textiles be used in orthopedic braces or supports?

- Yes, glass fiber textiles can be used in orthopedic braces or supports. Glass fiber textiles, also known as fiberglass textiles, are strong, lightweight, and have excellent mechanical properties, making them suitable for various applications in the medical field, including orthopedic braces and supports. Orthopedic braces and supports are used to provide stability, immobilization, and support to injured or weakened body parts, such as joints, muscles, or bones. These devices are designed to promote healing, reduce pain, and improve mobility. Glass fiber textiles can be utilized in the construction of these braces and supports due to their unique properties. The high strength-to-weight ratio of glass fiber textiles makes them an ideal choice for orthopedic braces and supports. They offer excellent tensile strength, allowing the braces to withstand the forces and stresses exerted on them during daily activities. Additionally, the lightweight nature of glass fiber textiles ensures that the braces are comfortable for the wearer, minimizing fatigue and discomfort. Another advantage of using glass fiber textiles in orthopedic braces and supports is their low thermal conductivity. This property helps in maintaining a consistent temperature around the injured area, aiding in the healing process and reducing inflammation. Furthermore, glass fiber textiles are non-allergenic and compatible with human tissues, making them safe for prolonged use. Glass fiber textiles can also be easily molded or formed into various shapes and sizes, allowing for customization and proper fit to the patient's specific needs. They can be used in combination with other materials, such as foam or padding, to enhance comfort and provide additional support. Overall, glass fiber textiles are a suitable material for orthopedic braces and supports due to their strength, lightweight, thermal properties, and compatibility with human tissues. They offer durability, customization, and comfort, making them a reliable choice for supporting and protecting injured or weakened body parts.

- Q: Can glass fiber textiles be used in protective gloves?

- Yes, glass fiber textiles can be used in protective gloves. Glass fiber textiles provide excellent resistance to heat, fire, and certain chemicals, making them suitable for use in gloves that require protection against these hazards.

- Q: Can glass fiber textiles cause skin irritation?

- Yes, glass fiber textiles can cause skin irritation. Glass fibers have sharp edges that can easily irritate and scratch the skin, leading to redness, itching, and discomfort. It is important to handle and wear glass fiber textiles with caution and consider using a protective barrier, such as gloves or a lining, to minimize skin contact and irritation.

- Q: Can glass fiber textiles be used in electronics applications?

- Yes, glass fiber textiles can be used in electronics applications. They are commonly used as insulation materials, reinforcing components, and substrates in electronic devices and circuit boards. Glass fiber textiles have excellent electrical insulation properties, high mechanical strength, and thermal stability, making them suitable for various electronic applications.

- Q: Can glass fiber textile be used in reinforcement materials?

- Yes, glass fiber textile can be used in reinforcement materials. Glass fiber textiles are commonly used as a reinforcement material in various industries such as construction, automotive, aerospace, and marine. They offer high strength, durability, and resistance to corrosion, making them an ideal choice for reinforcing materials.

Send your message to us

Glass Fiber and Ceramic Fiber Textiles for Refractory Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords