G303 stone for construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

roduct Name: | Grante stone / Prices of granite per meter / Granite |

Material: | Granite nature stone |

Sizes: | As per customer's requirement. |

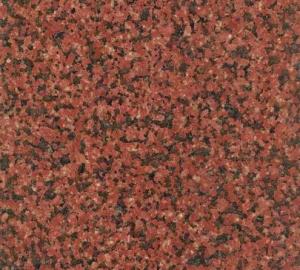

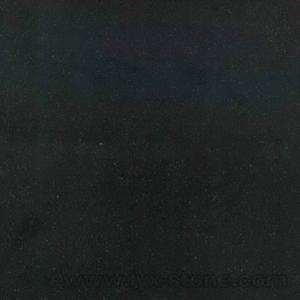

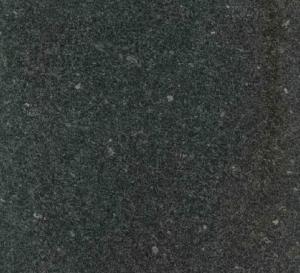

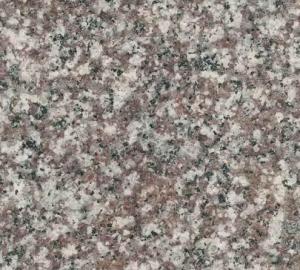

Available Colors: | black, green, brown, beige, yellow, grey. etc. |

Finished: | Bush-hammered, flamed, honed, polished etc. |

Usage: | countertop,floor tile,wall tile,paving stone,fireplace hearth,headstone |

Package: | Inner box, Strong seaworthy and fumigated wooden crates. |

1)Advantages

1)Our Brand:CMAX STONE is specializing in natural stone industry since 1998.

2)Design: As per clients' drawing or photos or as standard or by our design .

3)Advantages: Own factory, Own Quarry and R&D department, Own marketing team. Competitive are the quality & price of our excellent products

- Q: Are there any damage to the granite at home?

- Granite is a good material for the building, but some areas of granite will overflow radon, radon is a natural radioactive gas, will make people suffering from lung cancer. For the white, red, green and plaque granite in the light-colored series, it is not possible to think that the radioactive radiation intensity is large, and the radioactive radiation intensity may be too large in the following cases.

- Q: Why granite is not fireproof

- Granite (Granite), the main component of the continental crust, is a kind of magma in the surface below the formation of the magmatic rock, belonging to the deep intrusive rock. Mainly in the form of minerals such as quartz or feldspar. The granite language is the Latin granum, meaning grain or grain. Because granite is a deep diagenetic, often able to form a well-developed, visually discernible mineral particles, hence the name. Granite is not easy to weathering, beautiful color, the appearance of color can be maintained for more than a century, because of its high hardness, wear resistance, in addition to the use of high-level architectural decoration works, hall floor, or open-air carving of the preferred material.

- Q: Dry hanging granite how many square meters

- Dry hanging granite general price of 400 to 500 yuan (all materials + artificial) per square meter. Stone dry hanging method, also known as hanging method. Is the wall decoration in a new type of construction technology. The method of metal pendant will be directly attached to the decorative stone wall or hanging in the steel frame above, no grouting paste. The principle is the main structure of the main force on the point, through the metal pendant will be fixed in the building on the stone, the formation of stone decorative curtain wall.

- Q: The difference between granite and fire board

- Fire board - a method of processing granite, the first natural granite saw the plate, the surface of the plate after the initial grinding, after the first mill on the fixed frame, and then the surface of the first grinding flame burning Which is characterized in that the flame is sprayed with acetylene, oxygen and spray gun, and the flame moves evenly on the board surface at a speed of 120 to 250 mm per second and the distance between the nozzle and the board is 20 to 40 mm and Inclination, the flame temperature of 800 ~ 1000 ℃, the flame before the first spray on the plate before the water (to prevent the flame burning burned plate, the water heat absorption heat absorption)

- Q: What are the types of granite

- It is the hardest of all the granite, both indoors and outdoors. Talc granite is one of the most well-known granite forms because it is not well resistant to natural forces (wind and rain). This makes it less suitable for use as a floor, countertop and outdoor use for decorative purposes only.

- Q: Characteristics of white hemp granite

- White linen is a kind of granite, is an acidic igneous rock, the main component of silica, more than 70%. Texture is relatively hard, Shore hardness of 100 or more.

- Q: The same grade of marble and granite that expensive?

- The same grade of marble and granite compared to granite, because the granite corrosion resistance and weathering resistance is much stronger than the marble.

- Q: What does the granite mean?

- 614 Granite: 614 is the stone variety of the commodity number.

- Q: What is the main chemical composition of granite

- Granite is the main component of silica, its content is about 65% -85%. The chemical properties of granite are weakly acidic. Normally, the granite is slightly white or gray, with a dark crystal, the appearance of a spot, potassium feldspar to make it red or flesh. Granite slowly formed by the magma cooling crystallization, buried in the surface below, when the cooling rate is unusually slow, it forms a very rough texture of granite, it is called crystalline granite. Granite and other crystalline rocks form the basis of the continental plate, it is also exposed to the Earth's most common intrusive rocks.

- Q: What are the different treatments for marble and granite used indoors and outdoors?

- Marble: Marble mineral composition is simple, easy processing, the majority of fine texture, mirror effect is better. The disadvantage is the texture of the granite than the soft, heavy objects hit the vulnerable vulnerable to damage, light-colored stone easily contaminated. Because marble generally contains impurities, and calcium carbonate in the atmosphere by carbon dioxide, carbide, water vapor role, but also easy to weathering and erosion, leaving the surface soon lost luster. So most of the marble varieties should not be used for outdoor, generally only used for interior decoration. We have to deal with the different symptoms according to it. General use of renovation, crystal conservation

Send your message to us

G303 stone for construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords