FRP Winding Wire Continuous Equipment / Glass Fiber Pipe Making Line with High Quality on Hot Sale

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 24 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

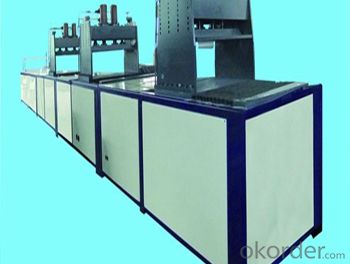

FRP Winding Wire Continuous Equipment / Glass Fiber Pipe Making Line with High Quality on Hot Sale

Product Description:

This production line is designed for producing FRP pipe.

Product Features:

1. Suitable to U-PVC,C-PVC,M-PVC,PP,ABS pipe extrusion.

2. Plastic pipe with various diameter and wall thickness, from 16-800mm.

3. The frp pipe making machine mainly includes single/twin screw extruder, pipe extrusion die, vacuum calibrating

water tank, spray cooling water tank, hauling unit, cutting unit and stack unit.The extruder is specially designed for

producing PVC pipe.

4. Supply technical service, formula guide and staple raw material purchase.

Product Parameter:

Name | FRP Winding Wire Continuous Equipment / Glass Fiber Pipe Making Line with High Quality on Hot Sale |

Brand | CMAX |

Weight | 5-13T |

Dimension(L*W*H) | 29*4.2*2.6m |

Power | 55-235KW |

Voltage | 220V/380V/440V |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Pipe |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Beijing, China (Mainland) |

Color | Blue |

Warranty | 12 Months |

Time of Delivery | 30-45 days |

Product Pictures:

Our Services:

1. Do free installation and trial run of microcomputer and equipment, do free training on operators, provide product

design software until personnel from your honorablecompany skillfully master it.

2. Responsible for providing advanced domestic production techniques and providing matching techniques and

equipment at any time following with development of production technology.

3. Within 12 months for all occurred troubles of the equipment we serve for you at any time to timely solve the

troubles.

4. According to the regulations in the contract timely provide wearing parts in production line and equipment

software data.

5. Assist you honorable company to do equipment reform or time changing work, assist you with upgrade work of

the production line.

6. Provide all involved service for production line.

FAQ:

1)Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your

machines running in order to keep your business running.

2) Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly

3)Q: How does your factory do regarding quality control?

A: Quality is priority. we always attach great importance to quality control from the very beginning to the end of the

production. Every product will be fully assembled and carefully tested before it's packed for shipment.

4) Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications.

5) Q: Can you make the machine according to my design or proto type?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine

that you are going to book with us

6)Q: How can we be assured that you will deliver us quality machine with spare parts?

A:1. Customers to send the technical people to our factory for checking the quality.

2.We can send the technicians to the buyer`s factory for the installation of the machine.

3.Good aftersales-service, its free of charge during the warranty period.

- Q: I want to use POM plastic to do mechanical disc cam, processed with sheet metal. (small dosage)Do other plastics have mechanical strength?

- Can be processed, but pay attention to cutting tools to be sharp, cutting force should be small, and fully cooled.The material is of good mechanical strength, and I know nothing in the plastic can match it.

- Q: What kind of equipment do household workshops need to process plastic products? Can you make money? What are the sales channels?

- The biggest investment is the injection molding machine, as well as three-phase power, it is best to understand the machinery will repair the mold, there is a stable processing order, you do not need to sell it!

- Q: What are the processes and machines used in the manufacture of plastic products?,

- In recent years, the proportion of plastic products is increasing rapidly in many fields, such as household appliances, instruments and meters, building materials, automobile industry, daily hardware and so on. The requirement of high precision and high performance of plastic products increases with each passing day, which makes the precision forming technology progress constantly. Injection molding is one of the most important plastic forming methods, and many factors affect the precision injection molding. 1. in the early stage of the design of plastic products, injection molding materials should be selected according to their application environment. 2. precision molds, rational design of precision injection mold is the basis and necessary prerequisite for precision products. Precision molds are indispensable to produce precision products. The precision of the die is usually affected by the temperature control of the die, the precise manufacture of the die and the choice of the plastic shrinkage when the die is designed. 2.1 control of the mold temperature due to the effect of mold temperature on shrinkage molding, but also directly affects the mechanical properties of plastic products, can also cause various defects of product surface flooding, so must keep mold in the specified temperature range, but also to make the mold temperature changes over time. In the injection molding of general precision parts, the temperature of the die is controlled mainly to increase productivity. But the impact of temperature control of mold for injection molding is great, it affects parts of the shrinkage, shape, crystallization, internal stress, so the design of mold hot loop temperature distribution at the request reasonable precise control accuracy, the best use of mold temperature machine and cold water machine control.

- Q: Method for producing plastic product

- Plastic products generally include plastic batching, molding, machining, bonding, finishing and assembly. The latter four processes are carried out after the plastic has been molded into products or semi-finished products. It is also called plastic two times processing. Key links in plastic processing of plastic products. The various forms of plastic (powder, granular, solution or dispersion) made products or blank of desired shape. As many as 30 kinds of molding method. Its choice is mainly determined by the type of plastic (thermoplastic or thermosetting), the starting form, and the shape and size of the product. Plastic processing thermoplastics commonly used methods are extrusion, injection molding, calendering, blow molding and thermoforming, etc., plastics processing thermosetting plastics generally use molding, transfer molding, injection molding. Lamination, molding and thermoforming are the processes of forming plastics on a flat surface.

- Q: How much is the investment? TenCan be processed daily plastic bags, woven bags, garbage bags, clothes bags, there are printed words like that.There is a 300 square foot factory empty home now, best can step can do this ~ ~ wherever he goes high profits? Just try to compare and see what is worth investing in! Trouble you expert pointing! Thanks.

- A full range of equipment from 30 thousand to more than ten thousand, depending on your investment situation, large processing plants have millions of!Towel disinfection profit space is very large, a towel in the cost of 1-2 hair, charge 5 cents a piece in some places (according to the local situation), investigate the market well, as long as the rent is not expensive, the development trend of this industry will be the future, and now a kind of tableware disinfection! It will be one of the most profitable industries!

- Q: Hello, small plastic processing plants need what equipment, how much the price, how to process, the size of the site, thank you

- An injection molding machine, 20 thousand to 30 thousand, a grinder less than one thousand, a dryer is oven, one thousand road two money. That's all

- Q: What kind of machine does plastic products factory use to produce plastic products?.

- Plastic and metal crafts of mass production are painted on the surface, generally divided into paint (pigment), color and polishing, color, usually by spraying, coloring and electroplating coloring.

- Q: where there are advanced environment-friendly recycled plastic processing equipment? Thank you

- Environmental protection recycling plant, this is a systematic project, the use of granulation machine is usually used granulator, need to be matched with waste water filtration, sedimentation, purification treatment pond, waste gas purification equipment.

- Q: When the engineering plastics in the processing, because it is not often around breaking chip, tool and workpiece, not only affects the working efficiency, but also the workpiece surface galling, do not know can not think of a way from the cutting tool and cutting amount? Who can give me some good advice? Please.

- Angle of feed, generally use 60 degrees bevel angle, the amount of cutting does not exceed 1MM. Also, adjust the cutting speed.

Send your message to us

FRP Winding Wire Continuous Equipment / Glass Fiber Pipe Making Line with High Quality on Hot Sale

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 24 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords