Composite Tank - FRP Tanks and Vessels with High Mechanical Strength in Various Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

INSTRUCTION

FRP tanks and vessels can be largely used in many areas of the light industry, petroleum, chemical, food brewing, transportation and so on. Such product can resist the corrosion of various acids, alkalis and salts.

CHARACTERISTICS

• High mechanical strength

• High mechanical inertness

• Resistance to weathering

• Low thermal and electrical conductivity

• Long Life

• Non-toxicity

• No need for maintenance

• Light weight

DESIGN PHILOSOPHY

The correct structuring of any kind of G.R.P. tank consist of three distinct types of layers:

• Chemical Resistant Layer

• Mechanically Resistant Layer

• Outer Protective Layer

OTHER DESIGN CONDITIONS

• Working pressure, Vacuum

• Support span

• Working temperature

CHEMICAL RESISTANCE

Resistance to corrosion in aggressive environments is one of

the primary reasons for specifying GRP tanks. These, resists a

wide range of chemicals and temperatures and can be built to

provide additional abrasion, weathering and fire resistance. The

chemical resistance of GRP tank depends primarily on the resin/

glass matrix used. Other factors can affect laminate resistance

including liner construction, cure, and fabrication methodology

and installation techniques.

General corrosion, galvanic, aerobic, pitting, dezincification,

graphitic and intergranular corrosion harm metals but not GRP.

PRODUCTION RANGE

FRP small-scale storage tank: Diameter ≤ 4M

Large-scale jobsite winding vertical storage tank: Diameter 4200mm-25000mm

EXECUTIVE STANDARD

FRP small-scale storage tank

JC/T587-1995 (Glass fiber reinforced plastic storage tank)

Large-scale storage tank

HG/T3983-2007 Industry standards of Chemical Corrosion-resistant jobsite Winding FRP Large-scale storage tank

HG/T20696 Design Requirements of FRP Chemical Equipment

COMPANY INTRODUCTION

CNBM, China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

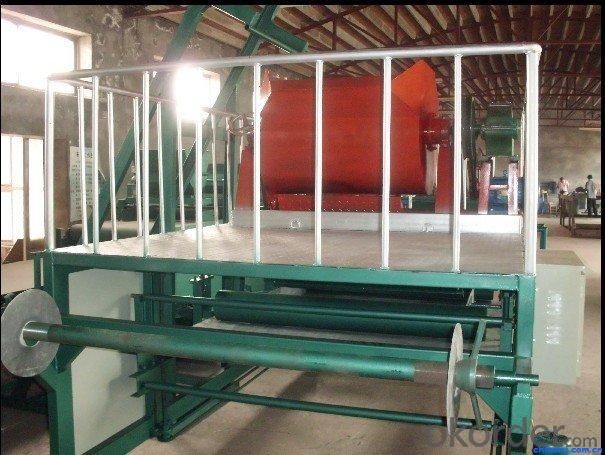

PICTURE S

- Q: What are the manufacturing processes of FRP tanks?

- The lining has the skeleton and the airtight function, is a part of the finished product. When designing the lining, pay attention to the sufficient strength and rigidity. The thickness of the inner layer is more than 3mm (see Table 1), and the resin content is greater than 80%. The corrosion resistant surface felt, short cut felt and cloth handle paste can be used for making the inner layer. Its production process is roughly as follows: mold making, mold, tank head hand paste glass fiber products, after curing, stripping adhesive, bonding head, air nozzle test, grinding, repairing, too. For the qualified lining lining molding, using two type sealing and simplified one and head connecting two. Thus, it is easier to produce a qualified lining and increase productivity than a three end combination of a sealed tail, a simplified type and a head. The key to making the qualified lining is the connection between the head and the cylinder. The head and the cylinder should be made of socket joint, because the plug joint has the advantages of high strength of joint, good performance of internal pressure, uneasy leakage and convenient assembly. As long as the socket structure is reasonable, it will not leak after use. The bonding joint depends on the resin cement and the outer FRP reinforcement. Wherein, the daub is applied between the socket and the socket and plays the first line of defense. It is made up of resin and filler, and resin has the function of adhesion and seepage prevention. It requires good toughness and higher adhesion, so epoxy resin should be used as daub. After the first line of defense, the seepage prevention mainly depends on the FRP reinforced layer. The layer consists of fiberglass products and resins. Among them, glass fiber products such as blankets and cloth between the fiber gap, can not be impermeable, can only play a strengthening role.

- Q: What should we pay attention to when installing FRP tank for hydrochloric acid?

- Because some of the hydrochloric acid tank plastic flange because of material than steel plate soft, in connection with other flanges, should pay attention to strengthening. The flange of the company supporting the factory general is tightening, in the transportation, loading and unloading may cause loose, check the user in the sealing performance should be used before the anti-corrosion tank, and observe whether liquid leakage. Tank containing hydrochloric acid for chemical liquid, it is best to test it with water to prevent loss.

- Q: How much can glass steel cans do?

- Due to the characteristics of FRP cans, FRP cans are widely used in the chemical, environmental, food, pharmaceutical, printing and dyeing industries, and gradually replace the majority of carbon steel, stainless steel market areas.

- Q: I am made of FRP equipment. Who needs FRP tanks?

- Created glass optimized software, optimized for high rate, perfect label printing

- Q: Is glass steel transparent? Transparent and opaque glass steel have?

- Glass fiber reinforced plastic to be pure and transparent is not possible, pervious to light can also be, pervious to light is to use transparent resin, without any filler and pigment, and the other is opaque glass fiber reinforced plastic

- Q: What are the advantages of FRP tanks?

- FRP tanks with corrosion resistance, high strength, light weight, long service life, because of its can be designed flexibly, process features strong, flexible design can be used in different industries such as chemical industry, environmental protection, food, pharmaceutical and other industries, is gradually replacing carbon steel, stainless steel parts market

- Q: What are the characteristics of FRP softened water tank?

- The water tank not only stores cold water, but also stores hot water. It has acid, alkali resistance, no seepage, no leakage and no deformation.

- Q: How can FRP tanks be installed on concrete foundations? Do you need a connection?

- It is recommended that a concrete ground beam be placed around the FRP storage tank after the FRP storage tank is placed on the concrete foundation. The first is to secure the FRP tank, and the other is to avoid the collision between the FRP tanks and the other two.

- Q: What are the 4 layers of FRP tanks?

- Reinforcing layer: the load that bears all kinds of external pressure

- Q: Are there any design standards for FRP tanks?

- Basic characteristics of Yiyuan FRP storage tank:1. Excellent physical properties: the proportion of GRP is usually 1.5 -.9g/cm3, which is 1/4 - /5 of steel. Compared to steel, cast iron and plastic, the coefficient of thermal expansion of FRP is approximately the same as that of steel, and the heat conductivity is only 0.5% of that of steel.2 chemical corrosion resistance by choosing different kinds of resin, acid and alkali resistance of various salts and a variety of oils and solvents, can be widely used in various aspects of chemical corrosion, can replace stainless steel and precious metal materials.3, smooth wall, roughness coefficient n = 0.0084, good health performance, easy to clean, anti microbial corrosion, such as using food grade resin as substrate, non-toxic, tasteless, can ensure product hygiene requirements.

Send your message to us

Composite Tank - FRP Tanks and Vessels with High Mechanical Strength in Various Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords