Composite Tank - FRP Tanks and Vessels with High Mechanical Inertness in Various Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 13 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

INSTRUCTION

FRP tanks and vessels can be largely used in many areas of the light industry, petroleum, chemical, food brewing, transportation and so on. Such product can resist the corrosion of various acids, alkalis and salts.

CHARACTERISTICS

• High mechanical strength

• High mechanical inertness

• Resistance to weathering

• Low thermal and electrical conductivity

• Long Life

• Non-toxicity

• No need for maintenance

• Light weight

DESIGN PHILOSOPHY

The correct structuring of any kind of G.R.P. tank consist of three distinct types of layers:

• Chemical Resistant Layer

• Mechanically Resistant Layer

• Outer Protective Layer

OTHER DESIGN CONDITIONS

• Working pressure, Vacuum

• Support span

• Working temperature

CHEMICAL RESISTANCE

Resistance to corrosion in aggressive environments is one of

the primary reasons for specifying GRP tanks. These, resists a

wide range of chemicals and temperatures and can be built to

provide additional abrasion, weathering and fire resistance. The

chemical resistance of GRP tank depends primarily on the resin/

glass matrix used. Other factors can affect laminate resistance

including liner construction, cure, and fabrication methodology

and installation techniques.

General corrosion, galvanic, aerobic, pitting, dezincification,

graphitic and intergranular corrosion harm metals but not GRP.

PRODUCTION RANGE

FRP small-scale storage tank: Diameter ≤ 4M

Large-scale jobsite winding vertical storage tank: Diameter 4200mm-25000mm

EXECUTIVE STANDARD

FRP small-scale storage tank

JC/T587-1995 (Glass fiber reinforced plastic storage tank)

Large-scale storage tank

HG/T3983-2007 Industry standards of Chemical Corrosion-resistant jobsite Winding FRP Large-scale storage tank

HG/T20696 Design Requirements of FRP Chemical Equipment

COMPANY INTRODUCTION

CNBM, China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products, professional service and complete solution to our customers. Strong delivery capacity, advanced technology

& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

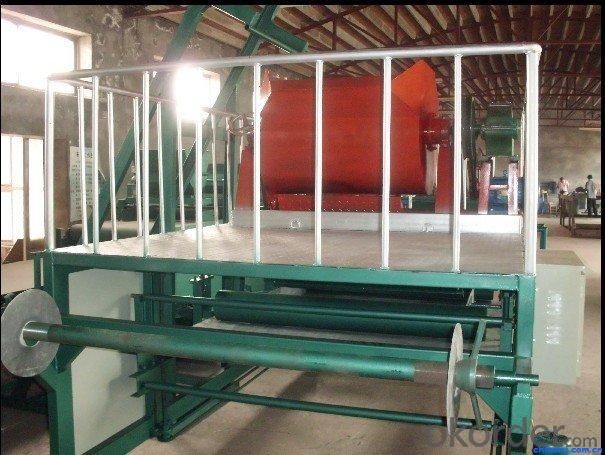

PICTURE S

- Q: What are the features of FRP tanks?

- Tightness is good, never leak, the traditional septic tank is very easy to leak, easy to pollute the ground water, from the floor is generally the smallest, not less than 5 meters. The Chinese style glass septic tank has advanced technology, integrated production, no cracks and no leakage. It can completely avoid the contamination of ground water by the traditional septic tanks and affect the safety of buildings.

- Q: What aspects of FRP tanks are used in general?

- Glass fiber reinforced plastic has good chemical resistance and is widely used in acid, alkali and high temperature resistant containers

- Q: Can formaldehyde be used in FRP tanks?

- FRP has good organic solvent resistance and can be used as formaldehyde storage tanks

- Q: To make a high quality FRP tank, is the hardware construction important to the quality?

- They are not lying are winding process, but the drum mold and the coil made out of the tank quality difference of several grades, or why only the strength of the manufacturers will be on the drum mold, because the drum made lining is the no formation of the uniform wall thickness of gas bubble, with pneumatic demoulding demoulding no damage to the lining, the lining is the most intact Guan Jian lock and barrier factors all corrosive substances to penetrate the layer structure.

- Q: How can the glass steel tank mould be made?

- 2000 cubic meters of glass reinforced plastic tanks, the cost of making a single mold is very high, and can find FRP manufacturers to site winding. If you insist that you can only use the mold with mold

- Q: Is FRP tank corrosion resistant?

- FRP tanks are resistant to corrosion.

- Q: How much is a 20 cubic meter of steel storage tank?

- If it is stored water, not invoiced about 30 yuan a kilogram, glass fiber reinforced plastic density of about 1.1. Count yourself.

- Q: Can FRP withstand 15% of sulfuric acid and nitric acid mixture?

- Yes. GRP is not made of steel. It is commonly called glass fiber reinforced plasticFRP (Fiber, Reinforced, Plastics), that is, fiber reinforced plastics, generally refers to the use of glass fiber reinforced unsaturated polyester, epoxy resin and phenolic resin matrix

- Q: What are the characteristics of FRP softened water tank?

- Long service life. A stamping molding plate (3-4 times stamping plate bearing capacity of ordinary plate).

- Q: Dongfeng scenery 330 glass washing liquid tank

- Corrosion resistance, by using different types of resin, resistance of various acid, alkali and salt and a variety of oils and solvents, can be widely applied to various aspects of chemical corrosion, can replace stainless steel, non-ferrous metals and other materials

Send your message to us

Composite Tank - FRP Tanks and Vessels with High Mechanical Inertness in Various Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 13 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords