FRP special shaped sheet production line

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 3 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Special Shaped Sheet Production Line

Installation Size : 50/65*2/3*3.5 m (L*W*H)

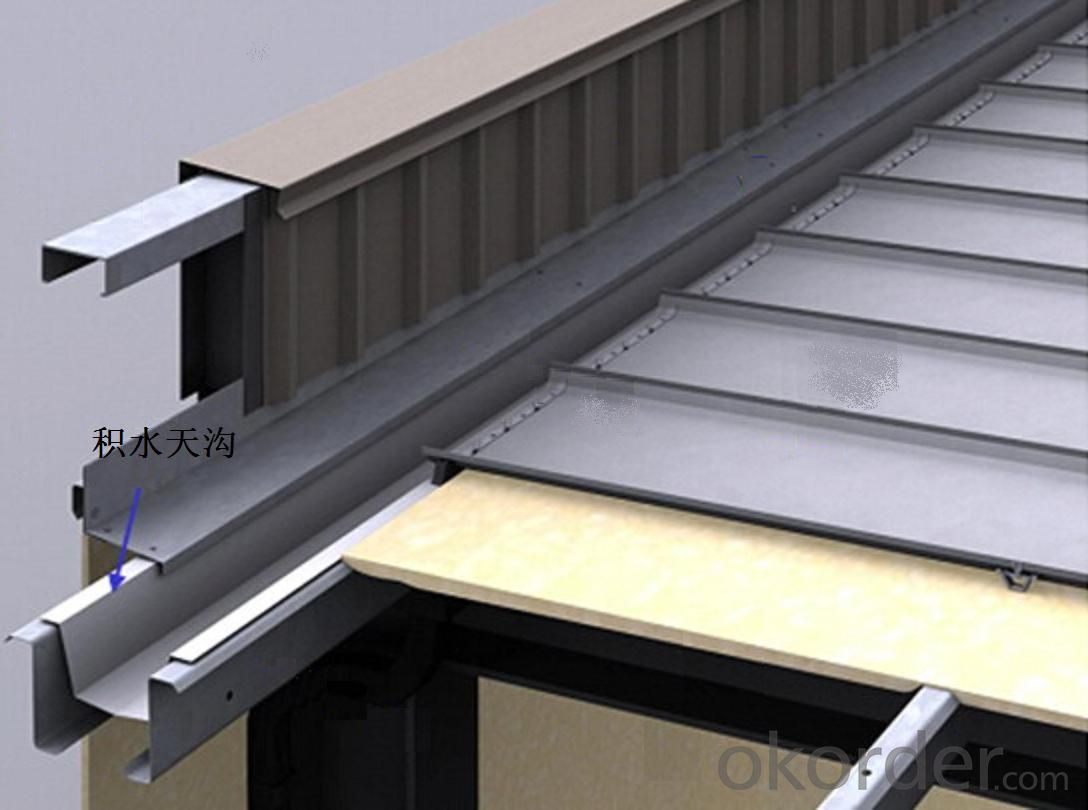

Production Range :special shaped sheet,gutter and special shaped corrosion resistant sheet of different colors.

Installed Power: 80kw-120kw

Required Power : 60-90 kw

Production Efficiency :2-6m/min

Sheet Thickness :2.0-5.0 mm

Materials: unsaturated ployester resin, fiberglass chopped strand mat,glass fiber roving,BOPET film,pigment,curing agent and accelerator.

Applications :Roof drainage, irrigation, and other special purpose products,etc.

We are a professional Hightech company manufacturing FRP sheet making machine. We have developed a complete technology system of manufacturing FRP sheet facilities,automatic production control and sheet forming process. This system has played an important role in promoting production efficiency,reducing production cost and improving products' quality,gained a great acceptance from our customer.

Now,We have become a leading provider of FRP sheet forming equipment in domestic.

- Q: What are the plastic finishing machines?

- From the point of view of the structure and motion mechanism and machine, there is no difference between general machinery.Machinery, derived from the Greek Mechine and Latin Machina, originally referred to as "ingenious design", as a general mechanical concept, can be traced back to the ancient Rome period, mainly in order to distinguish between hand tools. The word "mechanical" in modern Chinese is the generic term for "Mechanism" and "machine" (Machine).

- Q: Does anyone know any machine for processing plastic products?.

- The injection molding machine, blow molding, rotational molding, thermosetting squeeze a lot

- Q: this month bought a 180 thousand of the equipment and issued a value-added tax invoices, this sum of money can be deducted? How much deduction?Previously fixed assets are not deductible? Is this a policy that has just been changed this year? What's the tax rate? Thank you!

- Can be deducted from the value-added tax invoices on value-added tax deductible, in addition to the purchase of equipment costs, if there are qualified transport documents, you can also by freight * 7% deduction of input tax

- Q: I am going to work as a worker in a plastics factory. I wonder if the work inside it is very polluting. Is there any harm to the health?

- Phthalates can pass through the plastic containers of food and water into the human body, such as canned food, coating, recycled milk and mineral water bottles, etc. two. Research shows that the fat content in canned food with higher food is more vulnerable to pollution, such as pork, anchovies, sardines etc.. Fetuses and infants and adolescents are most sensitive to it, and health is the most vulnerable.In order to reduce the adjacent benzene two formic acid ester for the human body, usually pay attention to it is best not to use the foam containers to instant noodles, do not use plastic containers containing PVC in the microwave heating entrance food. The correct way to do this is to heat the food in a heat-resistant glassware or ceramic.

- Q: I would like to open a small plastic daily necessities processing factory, want to buy such as plastic buckets, plastic basins, plastic small bowl machinery!

- Similar processing machinery, you can go to the machine processing and other similar websites to check

- Q: I haven't done it before, and I don't know how to do it Would you please tell me how to do this? How to do it? Good to do

- Good to do, there is money, what is good to do, grasp the source of raw materials ah, finished marketing ah!

- Q: What milling cutters are used for processing plastics?

- Therefore, the plastic processing, the tools used and the corresponding cutting speed, etc., should be adapted to plastic characteristics.With the usual knife like T15 but nagging note "don't have to wear the knife edged quickly.

- Q: How is the processing cost of plastic parts calculated? Would you please tell me how to calculate the processing cost of plastic parts? For example, how is the processing fee formed?

- Note: manufacturing costs include the following:Labor costs, wages and insurance paid for them.Manufacturing costs include the costs of workshop production, the necessary tools, tools, equipment, supplies, and power and energy costs of the workshop.Administrative expenses, expenses arising from management.Production cost: mainly refers to material costs.

- Q: What kind of equipment does the groove on the PP plastic board work on?

- It can be machined with a shaper or engraving machine

- Q: What equipment? How much money do not.. at first. There are several sets of injection molding machine can be about 2... Mainly plastic injection molding. The ABS PA PE PP PVC... Etc. in this area. Please know that a friend told Kazakhstan. Thank you.

- Do PVC also dedicated screw, because PVC easily decomposed, and after the decomposition of the cylinder, screw, as well as mold are corrosive. Other material requirements are not high, so when you buy the machine, you must tell the manufacturer of your material.Equipment needed:1. injection molding machine2. pumps {pumps cooling machine mold, two units, the single-phase can be}

Send your message to us

FRP special shaped sheet production line

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 3 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords