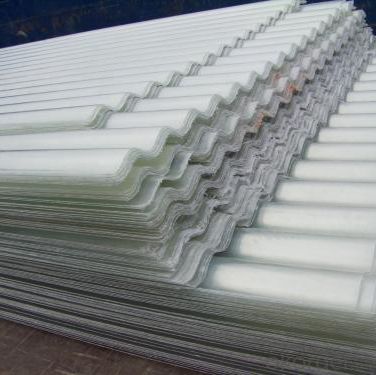

FRP Pultrusion Profiles - FRP Sheet with Anti-Ageing and High Quality at Good Prices in Latest Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION

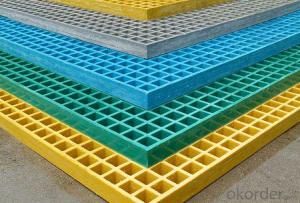

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

SPECIFICATION

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

PICTURES

- Q: Are FRP pultrusion profiles resistant to chemicals used in semiconductor manufacturing?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are generally resistant to the chemicals used in semiconductor manufacturing. FRP is known for its excellent chemical resistance, making it a suitable material for various industrial applications, including the semiconductor industry. The composite structure of FRP, consisting of a reinforced fiber matrix embedded in a polymer resin, provides resistance to a wide range of chemicals, including acids, alkalis, solvents, and other aggressive substances commonly used in semiconductor manufacturing processes. This resistance ensures that FRP pultrusion profiles can withstand exposure to these chemicals without significant degradation or corrosion, making them a reliable choice for use in semiconductor manufacturing environments. However, it is always advisable to consult the specific chemical resistance data provided by the manufacturer to ensure compatibility with the exact chemicals and concentrations used in a particular semiconductor manufacturing process.

- Q: Can FRP pultrusion profiles be used in electrical or telecommunications applications?

- Yes, FRP pultrusion profiles can be used in electrical or telecommunications applications. FRP (Fiber Reinforced Polymer) pultrusion profiles have excellent electrical insulation properties and are resistant to corrosion, making them suitable for use in electrical and telecommunications infrastructure. Additionally, their light weight, high strength, and design flexibility make them a desirable choice for applications such as cable trays, support structures, and enclosures in these industries.

- Q: Are FRP pultrusion profiles resistant to oils and greases?

- Yes, FRP pultrusion profiles are generally resistant to oils and greases. The combination of fiberglass reinforcement and resin matrix in FRP pultrusions provides excellent resistance to various chemicals, including oils and greases. This makes them suitable for applications where exposure to oils and greases is expected.

- Q: Can FRP pultrusion profiles be used in infrastructure projects?

- FRP pultrusion profiles are capable of being utilized in infrastructure projects, indeed. These profiles provide several benefits when compared to conventional materials, like steel and concrete. To begin with, FRP profiles possess a lightweight characteristic, while still maintaining high strength-to-weight ratios. This quality facilitates their transportation and installation, ultimately reducing construction time and expenses. Moreover, their lightweight nature ensures that they do not exert excessive loads on the supporting structures. In addition, FRP profiles exhibit resistance to corrosion. Unlike steel, FRP does not rust or corrode when exposed to harsh environmental conditions, making them ideal for infrastructure projects situated in coastal areas or regions with high humidity. This corrosion resistance extends the lifespan of the structures and diminishes maintenance requirements, resulting in long-term cost savings. Furthermore, FRP pultrusion profiles offer exceptional durability and dimensional stability. They display high resistance to fatigue, creep, and environmental degradation, guaranteeing the longevity and structural integrity of the infrastructure. Their dimensional stability also ensures that they retain their shape and structural properties over time, minimizing the risk of deformation or failure. Moreover, FRP profiles can be customized to meet specific project requirements. They can be manufactured in various shapes, sizes, and strengths, allowing for versatile applications in infrastructure projects such as bridges, walkways, railings, support structures, and utility poles. All in all, the utilization of FRP pultrusion profiles in infrastructure projects presents numerous advantages, including lightweight construction, corrosion resistance, durability, and customization options. These benefits establish FRP profiles as a viable and cost-effective alternative to traditional materials for a wide range of infrastructure applications.

- Q: Can FRP pultrusion profiles be used in protective barriers?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in protective barriers. FRP pultrusion profiles offer excellent strength, durability, and corrosion resistance, making them suitable for various applications including protective barriers. They can withstand impact, extreme weather conditions, and chemicals while providing a lightweight and cost-effective solution for barriers in industries such as construction, transportation, and safety.

- Q: Are FRP pultrusion profiles resistant to wear or abrasion?

- Yes, FRP pultrusion profiles are highly resistant to wear and abrasion. The combination of strong reinforcing fibers and a durable resin matrix makes them capable of withstanding harsh conditions and maintaining their structural integrity over time, even in high-stress environments. This resistance to wear and abrasion makes FRP pultrusion profiles an excellent choice for applications that require long-lasting and low-maintenance solutions.

- Q: Can FRP pultrusion profiles be used in automotive applications?

- FRP pultrusion profiles can indeed be utilized in automotive applications, presenting a myriad of advantages that render them appropriate for such use. Firstly, these profiles possess the dual attributes of being lightweight and strong, which holds immense significance within the automotive industry. As weight reduction stands as a top priority for enhancing fuel efficiency and performance, the commendable strength-to-weight ratio of FRP profiles enables the creation of lighter vehicles that consume less fuel. Secondly, FRP pultrusion profiles exhibit exceptional corrosion resistance, a vital characteristic for automotive applications routinely encountering exposure to various chemicals, moisture, and harsh environments. This corrosion resistance ensures the long-term dependability and durability of the profiles, ultimately reducing maintenance expenses and prolonging the lifespan of automotive components. Moreover, FRP pultrusion profiles offer remarkable design flexibility, thereby facilitating the formation of intricate shapes and geometries that can be customized to meet specific automotive requirements. This flexibility allows for the seamless integration of FRP profiles into numerous automotive components, including body panels, structural supports, interior trims, and suspension parts. Additionally, FRP pultrusion profiles demonstrate high fatigue resistance, a crucial aspect for automotive applications that involve repetitive loading and vibrations. The fatigue resistance of FRP profiles guarantees their enduring performance and aids in averting failures and breakdowns. Lastly, FRP pultrusion profiles are non-conductive, an advantageous attribute in automotive applications necessitating electrical isolation. This property obviates the necessity for supplementary insulation and mitigates the risk of electrical failures and short circuits. All in all, the amalgamation of lightweightness, robustness, corrosion resistance, design flexibility, fatigue resistance, and electrical non-conductivity renders FRP pultrusion profiles suitable for diverse automotive applications, thereby contributing to enhanced performance, fuel efficiency, durability, and safety within the automotive industry.

- Q: Are FRP pultrusion profiles resistant to acids?

- FRP pultrusion profiles, known as Fiber Reinforced Polymer pultrusion profiles, exhibit a notable resistance to acids. This corrosion resistance is a significant advantage that sets FRP apart from traditional materials like steel or wood. The composite materials employed in FRP pultrusion profiles display exceptional resistance to a broad spectrum of acids, including organic and inorganic varieties. The ability of FRP pultrusion profiles to resist corrosion can be attributed to the chemical composition of the composite materials. The reinforcing fibers, such as glass or carbon fibers, exhibit a high resistance to acid attacks. Furthermore, the polymer matrix used in FRP acts as a protective barrier, preventing acid penetration. It is important to acknowledge, however, that the resistance of FRP pultrusion profiles to acids may vary depending on the specific type of acid and its concentration. While FRP generally offers resistance against most acids, certain aggressive acids or highly concentrated solutions may cause some degradation over time. For optimal performance and durability, it is advisable to consult the manufacturer or supplier of FRP pultrusion profiles for precise information regarding their resistance to acids. They can provide valuable guidance on the suitability of FRP profiles for applications involving acids and recommend additional protective measures, such as coatings or liners, if necessary.

- Q: Can FRP pultrusion profiles be used in the construction of wind turbine blades?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in the construction of wind turbine blades. These profiles offer high strength-to-weight ratio, excellent corrosion resistance, and can be custom-designed to meet the specific requirements of wind turbine blade construction. Additionally, FRP pultrusion profiles provide flexibility in design and can withstand the demanding conditions of wind turbine operation, making them a suitable choice for blade construction.

- Q: Can FRP pultrusion profiles be used in the construction of outdoor signage?

- Certainly, outdoor signage can utilize FRP pultrusion profiles. These profiles possess remarkable qualities, including durability, strength, and the ability to withstand different environmental conditions, rendering them ideal for outdoor use. Typically, these profiles consist of a combination of fiberglass reinforcement and resin matrix, resulting in a lightweight yet robust material. Outdoor signage often confronts harsh weather conditions, such as rain, sun exposure, and temperature fluctuations. FRP pultrusion profiles exhibit excellent resistance to corrosion, UV rays, and moisture, ensuring that the signage retains its structural integrity and visual appeal over time. Moreover, FRP pultrusion profiles offer customization options to fulfill specific design requirements, offering flexibility in creating distinctive and captivating outdoor signage. These profiles can be effortlessly shaped, cut, and assembled, making them a versatile choice for signage applications. In essence, the construction of outdoor signage can undoubtedly benefit from the use of FRP pultrusion profiles due to their durability, resistance to environmental conditions, and design flexibility.

Send your message to us

FRP Pultrusion Profiles - FRP Sheet with Anti-Ageing and High Quality at Good Prices in Latest Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords