FRP machinery manufacture light weight made in China with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 17 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

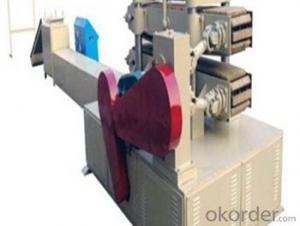

FRP machinery manufacture light weight made in China with high quality

Product Description:

1.The FRP production line occupe 20-30M at length, 3 meter at width, about 60-100square meter

2.The main machine is steel structure, stainless steel panel, side panle is paint.

3.Traction gantry make ordered according to requestd length.

4.Hydraulic station: we used the latest technology: pump is multi-group pump source (to ensure stability in forward speed.) Hydraulic parts are made of stacked clip (easy maintenance), and the tension and clamping force can make stepless adjustment. Traction speed with precision throttle, to ensure the stability of traction speed, and stepless speed adjustment of the traction. Hydraulic station with switch, so as to control the hydraulic oil heating up and down,so as to ensure the normal operation of the hydraulic system

Product Parameter:

Name | FRP machinery manufacture light weight made in China with high quality |

Brand | CMAX |

Weight | 8 ton |

Dimension(L*W*H) | 22mx3mx16m |

Power | 30KW |

Voltage | 380V |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Film |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Hebei, China (Mainland) |

Color | Selectable |

Warranty | 15 Months |

Time of Delivery | 30-45 days |

Product Pictures:

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be30-45days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

- Q: Consult, small toys, plastic products how to shine? What kind of machine or what kind of abrasives do you need? The swordsman knows to ask for help, if feasible, and to have a heavy score! This toy is made of diamond! It's about three or four centimeters in size! Urgent!

- One is to start from the mold and make the inner surface of the mold smooth!One is starting from the material, to make high light products, first of all, there must be good raw materials, and secondly, to have a good stain, high light color powder, to achieve free spraying, high light injection molding, first of all need to use high gloss plastic material.

- Q: What are the methods of forming plastic products introduced in this course?

- Commonly used molding methods have the following1, rolling formingCalendering is often used in thermoplastics. It is used to deliver plastic to a number of parallel, counter rotating hot rollers, which are rolled over many times2, tape castingCasting with dry plastic. It is soluble in the solvent of plastic, due to weight andspread to continuous operation of the metal belt, become thin layer of uniform thickness, then heating apparatus soft volatile agent, curing products, production of film or sheet.3, extrusion moldingExtrusion molding is often used in thermoplastics. This is a melt plasticized plastic which is extruded from the die cavity of the die at the head of the extruder and forms a profile similar to that of the die. It produces plates, pipes, bars, wires, profiles and so on

- Q: I found that the plastic bags and food bags used in the county town of my work are from abroad. I would like to open a plastic bag processing plant. What kind of machines do I need?. How much is it (cheaper, smaller per day)?. Where does the raw material go in?. The main market for vegetables; small bags for small food. Who will answer in detail?. Thank you

- Hello, the county bag if shipped from the field, the local should not do bags, it is a market.The machine used in plastic packaging food bags is film blowing machine and bag making machine. If you print words and patterns, add a printer. The price is not the same from more than 60000 to hundreds of thousands of different.

- Q: Which kind of engineering plastics has good processability?It requires small deformation and high machining accuracy when subjected to force

- Organic glass rods and plates, PTFE rod material, nylon rod, PVC sheet and other mechanical processing performance is good.

- Q: shopping bags, what equipment prices? Raw material type and material price? Please expert advice

- Need injection molding machine and blowing machine, raw materials can be used PE and PP plastic raw particles, using recycled particles, although it can reduce costs, but the quality of products as good as raw materials. To sum up, it is not easy to study a good market and choose a good one.

- Q: I did not come into contact with the plastic design, to understand the mechanical design and traditional design of plastic parts and fittings of the (metal material) are different, from what kind of material, design, drawing standards, labeling etc.. Please engage in plastic design industry heroes pointing!

- The design of plastic parts is quite different from metal parts. First of all, a wide range of plastic products, plastic parts, injection molding and other processing methods, suitable for mass production. Secondly, the plastic parts of the connection, using bayonet and so on, if the strength is not enough, auxiliary metal insert connection. Rarely threaded directly. Plastic parts should be considered demoulding, shrinkage, cooling variant, etc., consider equal thickness. Experience is more important than computation.

- Q: Plastics are processed into raw materials. How much raw material and energy do we need to process a kilogram of plastic?

- Is the necessary equipment for extrusion blow molding machine, you must first set up the company, production workshop, production equipment, testing equipment, inspection personnel and production licenses for the government, as the raw material is plastic particles, costs and profits can not be known, see you how to operate.

- Q: I would like to ask you how to produce plastic products, the need for mold, but also the need for large machinery, thank you all

- It depends on what kind of plastic products you make General use of the daily use of injection molding machines, water pipes, profiles, sheets need extruder, film type needs blowing machine, bottles need blowing machine, no matter which kind of mold is needed.

- Q: ABS plastic processing flow

- ABS resin is a three element copolymer developed on the basis of modification of polystyrene resin. A stands for acrylonitrile, B for butadiene, and S for styrene. ABS resin has three components, the comprehensive performance of A can improve the oil resistance, chemical corrosion resistance, which has a certain surface hardness; B ABS showed a rubbery toughness, improve impact toughness; S ABS plastics showed good fluidity, which has a good performance of thermoplastic plastic molding processing. ABS plastic is mainly used in the manufacture of instruments, instruments, household appliances, telephones, TV sets and so on. ABS plastic is used to make metal luster, and ABS is used instead of metal. Our factory produces various types of refrigerator liner and all kinds of plastic products, ABS injection products accounted for more than 88% of the total refrigerator plastic products

- Q: Is there any pollution in the processing of plastic raw materials?

- Yes, we have.The plastic itself contains chemicals, in the production process, will react with other substances, produce some odor and so on, so in the production environment must be ventilated, and will produce gas in the process of mechanical production, in production and after the residue, waste water and so on, these are the production of pollution.

Send your message to us

FRP machinery manufacture light weight made in China with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 17 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches