FRP Hydraulic Reciprocate Type Pultrusion Line/Machine on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 23 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

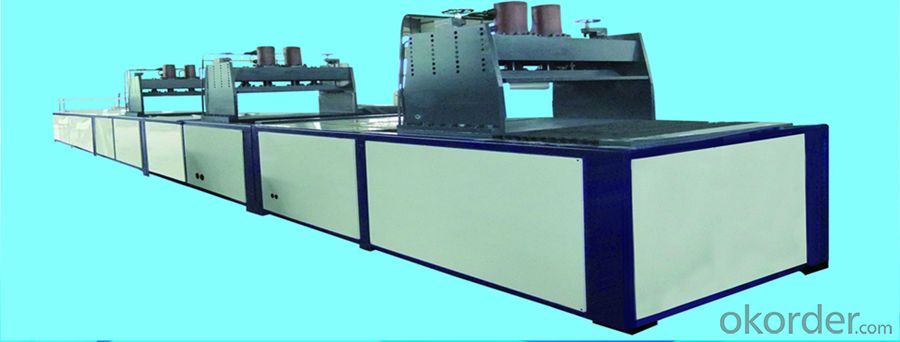

FRP Hydraulic Reciprocate Type Pultrusion Line/Machine on Sale

Product Description:

1.The main machine is steel structure, stainless steel panel, side panle is paint.

2.Traction gantry make ordered according to requestd length.

3.Hydraulic station: weused the latest technology: pump is multi-group pump source (to ensure stability in forward

speed.) Hydraulic parts are made of stacked clip (easy maintenance), and the tension and clamping force can make

stepless adjustment. Traction speed with precision throttle, to ensure the stability of traction speed, and stepless speed adjustment of the traction. Hydraulic station with switch, so as to control the hydraulic oil heating up and down, so as to ensure the normal operation of the hydraulic system

4.Using function: it have single and double manually operated gantry and double gantry automatic reciprocating running function. Automatic intermittent time can be automatically setted, and the actual production tension can be feedback.by sensor

5.Three-stage temperature control of thermal temperature control device, to achieve automatic control of heating

temperature of the mold.

Product Features:

1. Corrosion resistant

2. Light weight and high strength

3. Anti-ageing

4. Easy maintenance

5. Excellent electromagnetism property

6.Calorific property

Product Parameter:

Name | FRP Hydraulic Reciprocate Type Pultrusion Line/Machine on Sale |

Brand | CMAX |

Weight | 4000kg |

Dimension(L*W*H) | 20mx2.5mx2.2m |

Power | 15KW |

Voltage | 380V |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Granules |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Beijing, China (Mainland) |

Color | Selectable |

Warranty | 18 months |

Time of Delivery | 20-45 days |

Product Pictures:

Our Services:

1. Warranty period:18 months.

2. Spare parts: Non-artificial damage parts, during warranty period, can be provided free of charge

3. Testing and debugging: Every machine will be tested and debugged before shipment

4. Training and maintaining: Sending our engineer to your factory or sending your machine operator to our factory

FAQ:

Q:How do I know which is the right machine for me?

A:Just tell me what kind of product you want to make, and I will give suggestions according to it.

Q:How do I know the output range?

A:I will need size information (length, width, height) to calculate the weight of the product. And give suggestions due

to the products for you

- Q: What are the plastic finishing machines?

- Mechanical (machinery) refers to the general name of machines and institutions. Machinery is a tool that helps people to reduce their work difficulty or effort. Things like chopsticks, brooms and tweezers can all be called machines. They are simple machines. A complex machine consists of two or more than two simple machines. These more complex machines are usually called machines.

- Q: What is plastic processing of moulds?

- With the rapid development of plastic industry and the continuous improvement of general and engineering plastics in the field of strength, the range of application of plastic products is also expanding, and the consumption of plastic products is also rising.A plastic mold is a tool for the manufacture of plastic products consisting of a number of parts in which the molding cavity is formed. Injection molding, mold clamping in injection molding machine, the molten plastic is injected into the molding cavity, and cooling in the cavity shape, and then die down to separate out the system through the top products from the top of the left mold cavity, the mold is closed again for the next injection, the injection molding process is carried out of the cycle.The general plastic mould is composed of two parts, the moving die and the fixed mould. The moving die is installed on the moving template of the injection molding machine, and the fixed die is installed on the fixed template of the injection molding machine. In the injection molding, the moving die and the fixed die are closed to form a casting system and a mold cavity. When the mold is opened, the moving die and the fixed die are separated so as to remove the plastic product.

- Q: What kind of equipment do household workshops need to process plastic products? Can you make money? What are the sales channels?

- The biggest investment is the injection molding machine, as well as three-phase power, it is best to understand the machinery will repair the mold, there is a stable processing order, you do not need to sell it!

- Q: Plastic POM POM generally used for the production of what plastic products?

- Fire regulating ring, support member, gear, rack, rubber wheel, remote control switch bracket, cam pressure bar, cosmetic container, toy car runner, mobile phone chute

- Q: How much profit can a ton earn? Is it difficult to operate the program?

- Sichuan Ziyang shunmin plastic machinery specializing in the production of plastic granulator needs can choose according to the type of subjects ~ configuration price at around 50 thousand ~ a profit of around 8000

- Q: Which kind is with a lid, hollow, a little like PP material, white is a little transparent. It used to be filled with oil or wine. How is it processed? What company has custom-made?. Need to make the tank.

- The production of machine plastic barrels plastic pots, chemical barrels blow molding machine: fly HuaSu extrusion blow molding machine is a combination of extrusion machine and blow molding machine and a clamping mechanism, the extruder and the parison head and blowing device, a clamping mechanism, the parison thickness control system and a transmission mechanism. Parison head is an important component of the decision quality of blow molding products. Parison thickness control device is used to control parison wall thickness. Injection molding machine is a combination of injection molding machine and blow molding machine, including plasticizing mechanism, hydraulic system, control electrical equipment and other mechanical components. The common types are three station injection molding machines and four station injection molding machines. The three station machine has three working stations: Prefabricated parison, blow expanding and demoulding, each station is separated by 120 degrees. Four station machine is more pre molding station, each station is separated by 90 degrees.

- Q: I would like to ask you how to produce plastic products, the need for mold, but also the need for large machinery, thank you all

- Depending on what you do, different products have different requirements. Plastic products are injection molding, extrusion, injection blowing, extrusion and blowing equipment.

- Q: What mechanical products do you use to make this plastic product?! The more detailed, the better!

- I'm not sure about the mold design. You can find a device and ask for advice. Generally, they will be responsible for design and training

- Q: What kind of equipment does the groove on the PP plastic board work on?

- It can be machined with a shaper or engraving machine

- Q: How do we calculate the cost?

- Four major matters needing attention in investment of recycled plasticsPlastic recycling is a sunrise industry, the country, not only the effective utilization of resources and protect the environment, reduce the white pollution, from 2004 recycled plastics market, considerable benefits, as a new way of friends, is the author contact situation (editor's note), there are many aspects should be prepared in the first period, not to fight the battle without. The main problems are concentrated in the following aspects:1, blind follow-upAccording to the renewable materials market in 2004 prices, had been recycled most of the people have a better income, as for friends, in the test stage, on the surface has the advantages of simple process, low equipment investment, the product basically in short supply, technology content is not high, ordinary people can do at the same time, the raw material is us around the most familiar things, everywhere, everywhere can buy. Rough calculation, such as waste 2000 yuan can receive, the product can sell 4000 yuan, absolutely profitable.

Send your message to us

FRP Hydraulic Reciprocate Type Pultrusion Line/Machine on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 23 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches