FRP Flexible Making Machine with Good Price on hot sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 21 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Flexible Making Machine with Good Price on hot sale

Product Description:

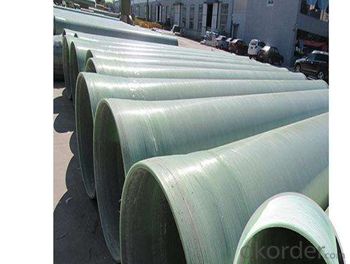

The products are widely applied to green house, skylight, porch, door, sandwich panel,ceiling, transportation body, concrete form and liner panels.

Product Features:

1.The main machine is steel structure, stainless steel panel, side panel is paint. With the two kinds of pultrusion modes:Debugging and succession, it is convenience to adjust the production craft;

2.Traction gantry makes ordered according to requested length.

3.The machine had two hydraulic pressure system, it had strong ability of anti interference;

4.Using function: it have single and double manually operated gantry and double gantry automatic reciprocating running function. Automatic intermittent time can be automatically settled, and the actual production tension can be feedback by sensor.

Product Advantages:

1.High productivity,light weight.

2.Easy to operate.

3.Good designability.

4.Enviromental protection.

Product Parameter:

Name | FRP Flexible Making Machine with Good Price on hot sale |

Brand | CMAX |

Weight | 8 ton |

Dimension(L*W*H) | 22mx3mx16m |

Power | 30KW |

Voltage | 380V |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Film |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Hebei, China (Mainland) |

Color | Selectable |

Warranty | 15 Months |

Time of Delivery | 30-45 days |

Product Pictures:

- Q: Processing method of PPS plastic

- For housing, structural parts, wear parts and sealing materials, such as: concrete pump casing, pump, valve, bearing, bearing bracket, piston ring and gear, pulley, fan, meter parts, flanges, Wan Xiangtou, counter, leveling. 2, electronic and electrical appliances: PPS for electronic and electrical appliances industry accounted for 30%, it is suitable for high temperature electrical components in the environment temperature higher than 200 DEG C; manufacturing generator and engine point rinse, rinse the electric coil, starter bracket, shield and leaf; on the TV, it can be used for high voltage shell and socket, wiring column and terminal plate; and a relay coil in the electronics industry, manufacturing transformers, resistance of the skeleton and shell, an integrated circuit carrier; using high frequency performance, manufacturing H bobbin and capacitor etc.. Micro electronic components, connectors, connector, socket, coil skeleton, Ma Dake, electromagnetic regulating plate, TV tuner shaft, relay, trimming capacitor, fuse holder, tape recorder, magnetic device and other components. Also used in precision instruments: computers, timers, speed machines, copiers, cameras, temperature sensors, and all kinds of measuring instruments shell and parts.

- Q: How does a lathe process a plastic flowerpot mold?

- The plastic flowerpot is made by plastic injection molding process, there must be a pot of injection mould, including mold cavity, guide column, return rod, push rod, plate, fixed plate, die angle, pouring mouth, bolts and other components, in the process of production and processing in addition to use lathe, planer, milling machine, grinding machine is also used, drilling and other equipment.

- Q: Which kind of plastic is good for machining?

- Generally can be processed, mainly in the tool and process control

- Q: What are the standard tolerances for engineering plastic products machined (e.g. lathes, milling machines)?

- No, look at the drawings, requirements, no note tolerances, drawings should be marked, and if there is no mark, then there is a problem with drawings. Drawing requires that all elements be annotated.

- Q: How should be the material after refining to smooth feeding, shredders or other equipment?.

- After refining can also screw? Open mill, mixer, used as rubber industry pro. The material on the twin screw extruder must be powder and pellets.

- Q: What plastic products are made out of machines? Is it an injection molding machine?

- According to the process, there are many kinds of processing equipment, not only the injection molding machine, as well as extruder.

- Q: I would like to open a small plastic daily necessities processing factory, want to buy such as plastic buckets, plastic basins, plastic small bowl machinery!

- Similar processing machinery, you can go to the machine processing and other similar websites to check

- Q: Where has the machine which sells the plastic processing, wants the true, begs the answer

- There is one in Hebei, TangshanTangshan plastics machinery

- Q: What chemicals should be used in plastic products?

- Additives mainly in the following categories:OneAntioxidantsAntioxidantUnsaturated double bonds in plastics are absorbed by oxygen atoms, heat and lightCaused by breaking, resulting in free radicals, which cause a chain reaction, so that the molecular chain scission or formation of chain cross-linking,Resulting in lower or weaker strength of plastic products. The function of antioxidants is to delay the oxidation of plasticsBreak down and prolong the life of plastic products. The antioxidants used in the plastics industry can be divided into functions: (One)Inhibitors of oxidative chain reactions, such as alkylphenolAlkylPhenolButyl tolueneButylatedHydroxytolueneAbbreviationBHT) aromatic aminesAromaticAmines) phenyl - -B-Resistant amine(Phenyl-B-Naphthylamine), were of Kun (AlkylQuinoneAlkenyl bisphenol A(AlkyleneBisphenolAlkyl phenol sulfideAlkylPhenolthioetherSalicylic acidBenzene fingerPhenylSalicylateAnd so on) etc.. (

- Q: tooling mold design, processing, whether the need for quality certification system?

- Management system certification is basically looking at the enterprise's own needs, nor is it mandatory, but if you are here, if useful in the car, you have to do TS certification

Send your message to us

FRP Flexible Making Machine with Good Price on hot sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 21 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches