Flexible Printed Standup Pouch With Bottom Gusset For Packing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

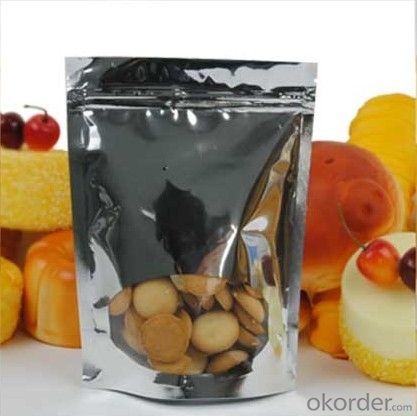

1. Description of Flexible Printed Standup Pouch With Bottom Gusset For Packing:

Flexible Printed Standup Pouch With Bottom Gusset For Packing are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Flexible Printed Standup Pouch with Bottom Gusset for Packing mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Flexible Printed Standup Pouch With Bottom Gusset For Packing:

Excellent quality control

Experienced factory produced

SGS passed

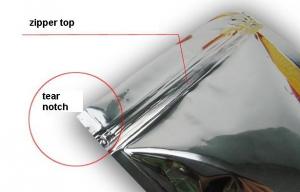

3. Flexible Printed Standup Pouch With Bottom Gusset For Packing Photos:

4. Flexible Printed Standup Pouch With Bottom Gusset For Packing Specification:

1. Material: PE,LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Flexible Printed Standup Pouch With Bottom Gusset For Packing:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Why a lot of the packaging bag surface is silver foil?

- Because candies are also considering moisture side so many sweets are wrapped in wax paper (because the wax paper can prevent water entering)For example, chocolate is a special kind of candy, its melting point is 36 degrees, it is very easy to get the temperature melting in the hand, so the reason is tin tin foil, the hands of the temperature can be very good to pass out to prevent the chocolate melts quickly.

- Q: What are the advantages and disadvantages of OPP and CPP membranes? What kind of bags are they used for?

- (steaming film) CPP, good heat resistance. Because the softening point of PP is about 140 DEG C, this kind of film can be used in hot filling, retort bags, aseptic packaging and other fields. With acid, alkali, grease resistance, making it bread products, packaging or laminated materials and other fields of choice. Its contact with food safety, demonstration of good performance, will not affect the flavor of the built-in food, and can choose different grades of resin to obtain the desired characteristics.

- Q: How do you determine the 210mm*300mm package and determine its version and length?

- Usually 1 meters, or 1 meters, 2 of the lengthWidth 300,3, leave 40 margin, roll on the design length of 940, version 420 weeks, diameter 133.75

- Q: Three layer coextrusion material for packaging bags

- Three layer co extruded films composed of outer layer of high mechanical strength polyester or polypropylene, elastic material mixed or SEBS intermediate layer is polypropylene with different proportion (SEBS), mixed layer is polypropylene copolymers with SEBS.

- Q: What kind of material is the express package on the market now? It's dark in the outer grey.

- The materials used for express bags are generally HD-PE, which can be recycled and can be re packed into bags

- Q: What does "13 silk" in vacuum packing bag mean?

- The vacuum packing bag 13 silk refers to the vacuum packing bag's thickness is 0.13 millimeters.

- Q: Can aluminum packaging bags be recycled?

- This separation technique is still under study, and no practical solutions are reported.

- Q: What kind of packaging bag does polysilicon use?

- Disposable material into a double-layer polyethylene bag, and then packing bags into the packing box or packaging barrel. Block polysilicon packaging specifications are net 5000g or 10000g per bag.

- Q: Can the meat with plastic packing bag be pressed directly with a pressure cooker?

- The plastic composite film (bag) products used in food packaging have 8 national and trade standards, and the main standards are divided into physical and mechanical performance indexes and sanitary performance indexes. The indexes of physical and mechanical properties are mainly tensile strength (or tensile strength), elongation, peel strength, heat resistance strength, Charpy impact energy, water vapor permeation amount and the amount of oxygen through the bag, bag, pressure resistance, heat resistance and dielectric performance drop, oil resistance, cold resistance, heat resistance etc.;

- Q: How many kinds of packing bags are there in the packaged foods?

- You ask about food plastic packaging, it is generally packaged with composite bags, composite materials, polyethylene (PE), polypropylene, nylon, polyester. These are the main membranes. The film is made of stretch film and blow film. Dry frozen goods, generally cooked with PET/PE., such as high temperature, it is generally nylon, composite CPP, or other composite, many kinds. I am in Dongguan, Humen, food packaging, such as alcoholic peanuts, bags, red dates bags, mask packaging bags, washing powder bags, areca bags, milk powder bags, small fish bags.

Send your message to us

Flexible Printed Standup Pouch With Bottom Gusset For Packing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords