Finger-Jointed Core Black Film Faced Ceiling Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

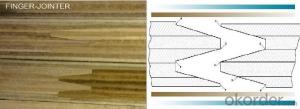

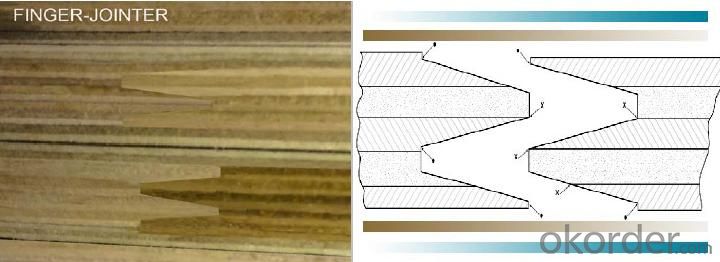

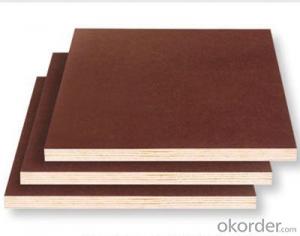

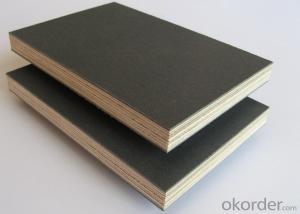

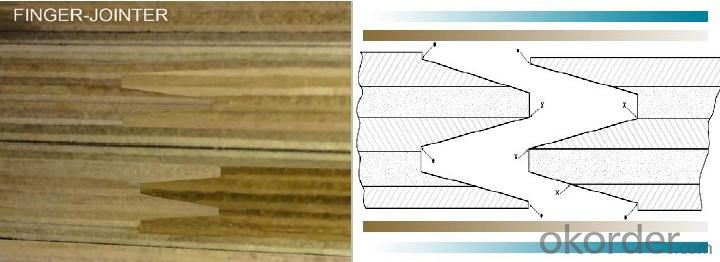

Finger-Jointed Core Black Film Faced Plywood

Specifications of Finger-Jointed Core Black Film Faced Plywood

Detailed Product Description | ||

Place of origin | China | |

Core | Poplar | |

Size | 1220*2440mm and as your requirement | |

Thickness | 12mm to 30mm and as for your requirement | 1/2 inch(12-12.7mm) |

5/8 inch(15-16mm) | ||

3/4 inch(18-19mm) | ||

Thickness tolerance | 12-30mm: +/-0.3mm | |

Glue | MR,E1,E2,Melamine,WBP Phenolic | |

Moisture | 10%-15% | |

Joint way | Overlap joint, end joint, scraf joint, finger joint | |

Strength | High bending strength Strong nail holding | |

Quantity | 8 pallets/20ft,16 pallets/40ft,18 pallets/40HQ | |

Usage | construction, Furniture, decoration, packing. | |

Certificate | ISO9001: 2000; CE; CARB | |

Main market | Middle East, South Asia, South America, Africa | |

Shipment & payment | ||

MOQ | One container | |

Port | Qingdao | |

Packing details | Inner packing: 0.2mm thick plastic bag Outer packing: pallets covered with plywood/carton, then steel taped for strength | |

Delivery time | 2 weeks after your deposit | |

Payment | T/T, 30% deposit, the balance against the copy of B/L, L/C at sight. | |

Advantage | ||

Capacity: 6000 CBM per month | ||

Sample available | ||

high quality and competitive price | ||

10 years’ experience in export | ||

Packaging & Delivery

Packing For transportation of Ocean and Land, Inside Pallet is wrapped with 0.2mm plastic bag, Steel strip or PVC for strength, More than 2mm plywood sheet or hard paper covering all the sides left, right,top and bottom.

Delivery will be proceed with 15days after receiving deposit or Original L/C at sight.

Photo:

FAQ:

① why from okorder?

Okorder is a qualified supplier of all kinds of building matierials in China. All products have been showed in Okorder website are under well controlled by okorder QC team.

All products had been produced under a clear quality standard and the quality is consistence among the shipments.

Okorder has already setted up more than 20 warehouses in different markets to show the products. You are convenient to know the products from your local place and it will help you to make decision easyly.

②How to guarantee the quality of the products?

We have established a perfect quality management system,as for raw material and semi parts all are under strict quality test and we have a IQC system to control the purchases.

QC on site is very strict and all steps of process are measured per drawings. Before delivery, we set a OQC system to make sure each piece meet the standard of order.from design to delivery,

③How long can we receive the product after purchase?

Lead time depending on order quanity, The normal order can be deliveried with 3 weeks.

- Q: Why plywood is cheaper than solid wood

- and then made of adhesive glue from the three or more layers of plate-like material, usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other

- Q: triple? Nail gun Self-tapping screws? Cork Or other?

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other

- Q: What are the further processing of plywood?

- plywood plywood through mechanical finishing or gluing, such as cutting, profiling sawing, hitting, drilling, milling and other processed plywood

- Q: Plywood is a common material for furniture?

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: Furniture solid wood and plywood which is better? Such as bed `wardrobe` TV cabinet `table

- on the requirements of the multi-layer solid wood flooring as strict, which is our daily common plywood or plywood bending reasons.

- Q: What is the density of plywood?

- Plywood can improve timber utilization and is a major way to save wood

- Q: What are the defects of the plywood?

- The intergrown knots are formed by the tree's live technique. Knots and the surrounding wood close together or with the surrounding wood part of the length of its cross-section than the length of 3/4, hard texture, normal structure

- Q: Decorative veneer veneer plywood features

- The product is natural and rustic, natural and noble, can create the best and elegant living room environment

- Q: Plywood quality requirements include appearance level, size, physical and mechanical properties of the three elements.

- Thickness from 4mm below the thin plywood. 3mm, 3.5mm, 4mm thick plywood for common specifications

- Q: The usual length and width specifications are:

- 1220 × 2440mm, while the thickness specifications are generally: 3,5,9,12,15,18 mm and so on.

Send your message to us

Finger-Jointed Core Black Film Faced Ceiling Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords