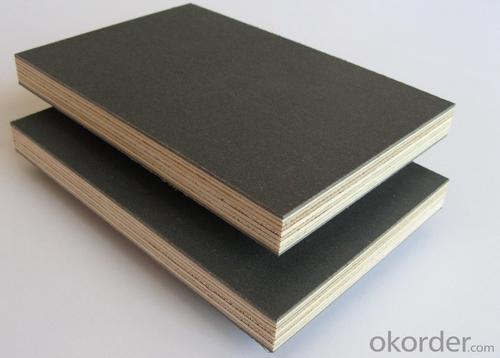

3/4 Plywood Actual Thickness Film Faced Plywood for Construction with Combi Core

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

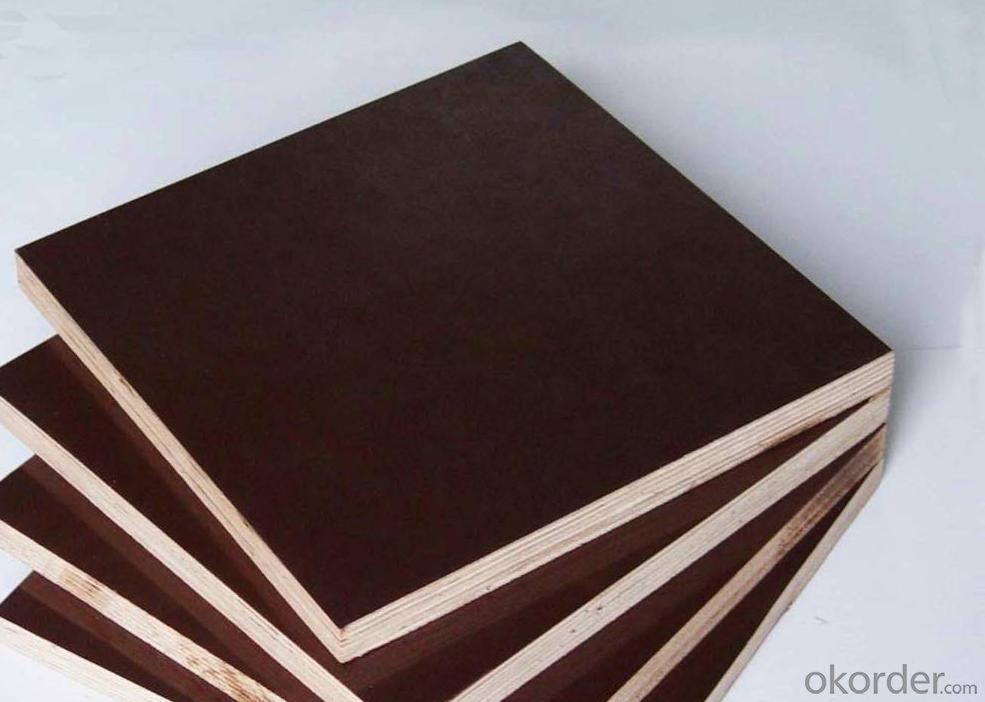

1.High bending strength

2.Strong nail holding

3.Moisture-proof and easy work

4.Tight construction and high strength

5.No ratten or decay

6.Low formaldehyde emission

7.The productions are suitable for the construction of viaduct and tall frame building

8.If put in boiling water for 48 hours,it still glue sticking and still formed

9.If used abide by illustration strictly,it can be reuse more than 50 times

10.Solve the problem of leaking and rough surface during construction process

Features

1. Excellent performance of flame retardant;

2. High chemical stability and Anti-aging;

3. Excellent performance of bonding, coating and machining;

4. Mechanical properties meet the requirements of first-class product to national standard;

5. Non-toxic, non-polluting;

6. Non-corrosive metal;

7. Improved performance of Anti-Mildew;

8. Free formaldehyde content superior to class E1 of GB;

9. Low smoking and the high level of safety.

FAQ

1.free samples are available

2.MOQ is one 40HQ container

3.delivery time 30 days after getting deposit

4.payment term T/T or L/C at sight

Packaging & Delivery

Packaging Detail: Inter packing: 0.20mm plastic bag;Outer packing: pallets are covered with plywood or carton

and then steel strips for strength

Delivery Detail: 15days after received 30%TT as deposit

commercial plywood

Specifications

1.commodity:commercial plywood.

2.size: 1220x2440mm, 915x2135mm.

3.thickness: 1.7-30mm.

4.glue: MR, E2, E1, E0, MEL, WBP.

Good quality commercial plywood for furniture use

Conventional data: | Size: | 1220mm*2440mm&1250mm*2500mm or as your demand | ||

1/8inch(2.7-3.6mm) | 3mm = 112sheets/cbm | |||

1/4inch(6-6.5mm) | 6mm = 56sheets/cbm | |||

Thickness: | 3/8inch(8.5-10.2mm) | 9mm = 37.33sheets/cbm | ||

(2.0—30mm) | 1/2inch(12-12.7mm) | 12mm = 28sheets/cbm | ||

5/8inch(15-16mm) | 15mm = 22.4sheets/cbm | |||

3/4inch(18-19mm) | 18mm = 18.66sheets/cbm | |||

Core: | poplar,hardwood,combi core etc | |||

Glue: | E0 , E1,E2,MR,WBP, MELAMINE | |||

Face/back: | okoume,bintangor,keruinging,poplar,pine,melamine paper etc | |||

thickness of faced: >= 0.45mm | ||||

Grade: | AAA first class | |||

Moisture: | <12%< span=""> | |||

Thickness tolerance: | (+/-)0.5mm | equal to and more than 12mm | ||

(+/-)0.3mm | less than 12mm | |||

Physical parameters: | density:>520—650G/cbm | |||

modulus of rupture: > 30Mpa | ||||

modulus of elasticity :>6000Mpa | ||||

Standards: | Plywood grading standard for USA order | |||

Export standard packing: | inner | pallet lined with 0.2mm plastic bag | ||

Outer | outside covered with carton then steel strip for strength, the bottom with regenerative wood pallet | |||

Quantity: | 20'GP | 8 Crates/12000kgs/21.43cbm | ||

40'GP | 16 Crates/24000kgs/42.87cbm | |||

40'HQ | 18-19 Crates/28500kgs/48.23cbm | |||

Delivery time: | 15 days after order confirmed | |||

Term of payment: | L/C at sight, T/T | |||

Capacity: | 5000 Cubic Meter / Month | |||

Certificate | CE,CARB,FSC,ISO9001,ISO14001 | |||

- Q: triple? Nail gun Self-tapping screws? Cork Or other?

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: Class I resistant weather plywood Class II water resistant plywood

- Hard fiber board sound absorption, waterproof performance is good, durable, easy constructio

- Q: How do you choose plywood in plywood production?

- But should be described in the name of the product, such as "cedar veneer plywood", or "fir slices plywood", or "cherry wood trim".

- Q: Multilayer plywood with what method is fixed

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other

- Q: A brief introduction to plywood

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q: The Preparation of plywood ingredients

- veneer veneer mountain peeling, semi-circular peeling, slicing or sawing the production of flakes of wood.

- Q: Ordinary plywood is divided into four categories

- Thickness specifications for the 6,9,12,15,18 and so on. The main performance indicators for the water content of 4 to 13%, the expansion of water thickness ≤ 12%, as well as tensile strength, bending strength, grip nail force.

- Q: What is a joinery board?

- The center plate of the blockboard should have the same direction of grain and perpendicular to the texture of the core.

- Q: Decorative veneer veneer plywood features

- Decorative veneer veneer plywood is one of the most commonly used materials for interior decoration

- Q: Does plywood contain formaldehyde?

- 12 cm plywood is usually 3-4 layers of natural wood chips "glue" together, each layer of double-sided roller plastic hot forming, the whole board about 3 kg of glue

Send your message to us

3/4 Plywood Actual Thickness Film Faced Plywood for Construction with Combi Core

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords