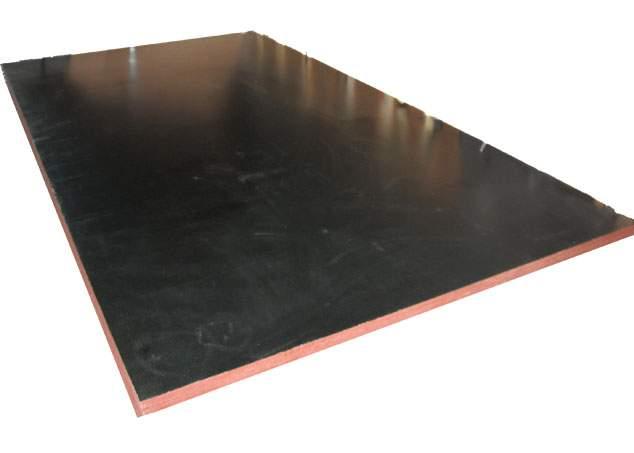

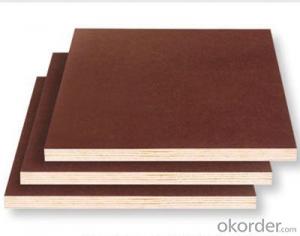

1 2 Inch Plywood Lowes Film Faced Plywood for Construction with Brown Film

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

Item:film faced plywood

Size:1220x2440mm

Thickness:9mm,12mm,15mm,18mm,20mm,25mm,customer's thickness is available

Color:Brown,Black,Red

Description:

Face/Back | Black film/brown film |

Color | Black,brown |

Core: | Poplar,hardwood,combi |

Grade: | Construction grade |

Glue: | MR/Melamine/WBP |

Size(mm) | 1220x2440mm,1250x2500mm |

Thickness | 9mm/12/mm/15mm/17mm/18mm/19mm/21mm/23mm/25mm |

Moisture | 8-16% |

Packing | Inter packing:0.2mm plastic; Ourter packing:bottom is pallets, covered with plastic film,around is carton or plywood, strenghthen by steel or iron 3*6 |

Usage | used for construction |

Minimum Order | 55CBM,1x40HQ |

Payment | T/T or L/C at sight |

Delivery Time | Within 20 days receiving deposit or original L/C at sight |

Features:

1. Transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2. After installation of concrete, the surface looks like a mirror. (the cement does not stick.)

3. You are able to use film faced plywood until the plywood itself is damaged. (Strong with nailing and knifing)

4. Environmentally friendly. (Even after incineration, there is no hazardous substance.)

5. It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time

Sealing of Edges:

Phenolic film faced plywood edges are fully sealed by the factory and it is the most important that all edges remain sealed. to obtain full value from a phenolic film faced plywood sheet any recut edges should sealed as soon as possible with water proof paint sealing of holes.

Any hole made in film faced formwork panels should also be sealed to prevent water entering. if water does enter it may cause swelling around the holes.

FAQ:

1.Can I be your agent?

Yes, welcome to deep cooperation. We have big promotion in the market now. For the details please contact with our overseas manager.

2.Is OEM available?

Yes, OEM is available. We have professional designer to help your brand promotion.

3.Is the sample available?

Yes, samples are available for you to test the quality.

4.Are the products tested before shipping?

Yes, all was qualified before shipping. We test every batch every day.

5.What's your quality guarantee?

We have 100% quality guarantee to customers. We will be responsible for any quality problem.

6.What's benefit will you bring?

Your client satisfied on the quality.

Your client continued orders.

Your can get good reputation from your market and obtain more orders.

- Q: Why plywood is cheaper than solid wood

- commonly known as: multi-layer board) is one of the commonly used furniture materials, is a wood-based panel. Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood

- Q: Class I resistant weather plywood Class II water resistant plywood

- slab molding (mixing resin and additives pavement), under hot pressure, so that cellulose and Hemicellulose and lignin plasticized to form a plate.

- Q: What harm does the plywood factory work?

- Plywood using adhesives, containing benzene, toluene, xylene and other solvents, with the corresponding occupational hazards

- Q: What are the processing defects of plywood?

- Warping warPing is generally a regular deformation, part or all of the surface of the plywood is curved.

- Q: What are the defects in plywood material?

- Fissure check The short separation of the panel fiber usually does not start from the side of the board, not all extending through the thickness of the veneer.

- Q: What are the key points for plywood selection?

- may be damp the hidden parts and high demand for waterproof occasions should consider the use of Class I or II plywood, outdoor use of plywood should be used Ⅰ class plywood.

- Q: Ordinary plywood is divided into four categories

- According to different density, divided into 80, 70, 60 three categories. Quality level for the premium, one, two three

- Q: What is medium density fiberboard

- Its thickness specifications are 2.7,3,3.5,4,5,5.5,6,7,8 mm, commonly used specifications are 3,3.5,4 mm.

- Q: Solid wood and plywood which is better?

- in addition, also need to consider its ground load capacity and use In the geothermal thermal conductivity; and the general splint or plywood in this consideration is not much.

- Q: Poisoning diagnosis and grading standards

- chronic benzene poisoning and blood cell involvement and the series and extent, and whether the evil is divided into light, medium and heavy three.

Send your message to us

1 2 Inch Plywood Lowes Film Faced Plywood for Construction with Brown Film

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords