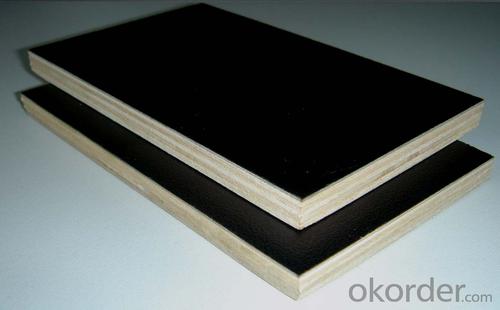

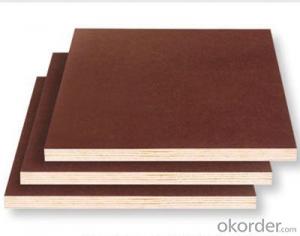

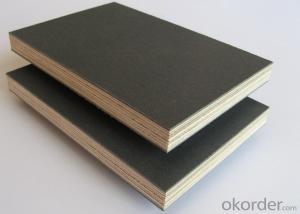

Bc Plywood Film Faced Plywood for Construction (Furniture Plywood)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

description

| Type: | Plywoods | Place of Origin: | Shandong, China (Mainland) | Brand Name: | KCF |

| Model Number: | 111 | Usage: | Outdoor | Grade: | First-Class |

| Main Material: | Poplar | Formaldehyde Emission Standards: | E1 | Plywood Type: | 13-Ply Boards |

| film color: | black and brown | glue: | mr and wbp | core material: | poplar,hardwood,birch and combine |

specification

1) Plywood:

- Core Material: Styrax, Eucalyptus, Canarium, Poplar,..ect

- Place of origin: Vietnam

Specifications:

- Size: 1.00m x 2.00m/ 1.22m x 2.44m

- Thickness: 8mm - 28mm

- Grade: AA/BB/CC

- Tolerance in thickness: +/-0.5mm

- Glue: MR, WBP, E0, E1, E2, Melamine

- Max thickness: 30mm

- Moist content: 10 - 12%

2) Film Faced Plywood:

- Demension: 1220mm x 2440mm/1250mm x 2500mm

- Grade: AA/BB/CC

- Thickness: 12mm, 15mm, 18mm, 21mm

- Thickness tolerance: -0.3mm & +0.5mm

- Core Material: Styrax, Eucalyptus, Canarium, Poplar,..ect

- Glue: MR, WBP, E0, E1, E2, Melamine

- Moist content: 10 - 12%

| Features | Transference to concrete is set up very easily. There is no need for any transference preparation. 1. Transference to concrete is set up very easily, so film faced plywood good for construction work. (There is no need for any transference preparation.) |

- Q: What is the composition of the plywood?

- Plywood usually refers to the plywood or multi-layer board, that is, with the same thickness of two or more layers of veneer plus glue from high temperature suppression

- Q: Selection of plywood in plywood production

- In the production of plywood, derived from a lot of color varieties, one of the most important one is in the original plywood board surface affixed with a thin layer of decorative veneer, known as decorative veneer veneer plywood, the market referred to as decoration Board or trim panel.

- Q: How to use building plywood?

- Four types of plywood for the tide resistant plywood, used in the indoor normal, general purpose plywood with beech, linden wood, ash, birch, elm, poplar and so on.

- Q: According to the different composition of the glue, for the construction of plywood with the following types of glue

- According to the environmental protection level, the glue used for plywood can be divided into E0 grade, E1 glue, E2 glue (and even E2 level are not reach the unqualified glue)

- Q: Multilayer board, also known as three plywood and plywood

- the plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like material

- Q: Now the market prospects for plywood

- total accumulated profit 3,198,494,000 Yuan, compared with the same period in 2005 increased by 60.41%.

- Q: Class III resistant tide plywood class IV tonic resistant plywood

- Mild wood veneer: with Ash, willow wood, color wood, birch and other peeling into 0.1-0.5mm thick sheet, plywood as a substrate made of glued, its beautiful pattern, good decorative

- Q: Decorative veneer veneer plywood features

- Decorative veneer is made of high quality wood by slicing or peeling processing made of thin wood chips.

- Q: One of the commonly used materials for furniture is a wood-based panel

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression

- Q: Solid wood and plywood which is better?

- Can not completely determine which is better, this depends on how you use the main.

Send your message to us

Bc Plywood Film Faced Plywood for Construction (Furniture Plywood)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords