Steel Plastic Composite Pipe Fiberglass Winding GRP FRP Pipe Price Fittings Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Fiberglass winding GRP FRP pipe price fittings Pipe

Pipe Introduction

It is the ideal product for the transportations of the chemicals, drinking water, waste water, waste gas and sewer.

Characteristics

• Corrosion resistance High mechanical property

• Low friction coefficient

• Light weight

• Non toxic

• Maintenance free

• Long life span

• Double O ring sealing joint make the pressurization

more convenient and unique.

• Convenient and quick installation

• Long life of more than 50 years

Production range

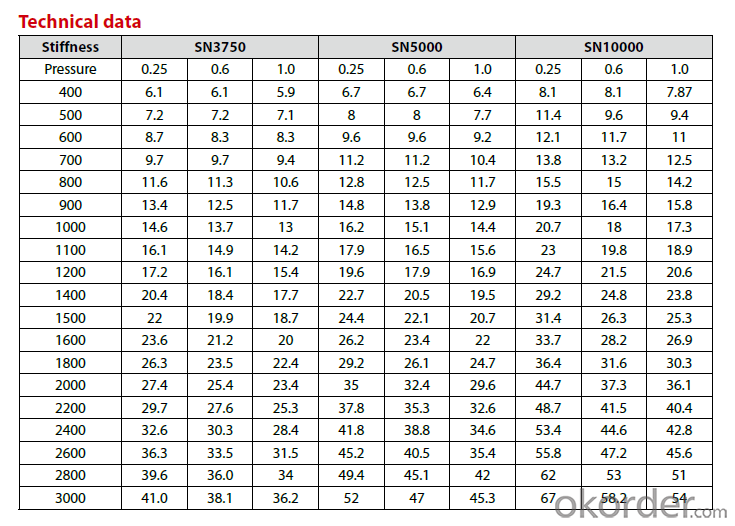

Any type and specification RPMP of diameter DN400-DN4000 and pressure PN0.25-PN2.5MPa can be produced.

Also, we can provide the customized product according to user’s specific requirements.

Application

Due to its own advantages, the RPMP is used extensively in the city engineering water supply and drainage,

the water supply and the drainage or the recycle water in the electric factory, the waste water treatment, the oil

chemical industry and so on.

FAQ

Q1.How do you deliver the goods to my country?

A:We can provide international express,such as DHL,EMS,UPS,FedEx,etc.We select air freight and sea freight upon your requests. Quotations if without mentioning the shipping costs are shipping fee excluded.

Q2.How to get the catalogue?

A:please contact us and tell us what you are looking for.

Packaging & Delivery

Packaging Details: normal export packages

Delivery Detail: Shipped in 15 days after payment

We will try our best to meet costomers' demands. Welcome you come here to visit us.

- Q: Why FRP pipes for outdoor waste gas treatment equipment are selected?

- Therefore, the outdoor waste gas treatment equipment is usually made of glass fiber reinforced plastic.

- Q: How can I replace the valve on the water supply pipe?

- Can be arranged according to the construction plan, the first excavation processing and then steel flange three pipe production, water supply operation again when all the preparatory work is completed, and according to the steel flange three pipe length decided to cut the glass steel pipes length;

- Q: The difference between FRP process tubes and GRP tubes

- Pure glass fiber reinforced plastic pipe relative to sand pipe prices higher, in addition, the two types of pipe applications in general have obvious differences, process tubes are used in chemical plants and other places, sand pipes are used in municipal.

- Q: FRP acceptance standard

- Perform hydrostatic test. In order to comprehensively check the installation quality of pipes, the pressure test shall be carried out according to the test methods stipulated in the code for construction and acceptance of water supply and drainage pipe works, and the allowable seepage water quantity shall be carried out according to the standards of the steel pipe.

- Q: Galvanized steel sheet and inorganic glass fibre reinforced plastic pipe are calculated according to this norm or norm

- The use of a fixed fare set without further consideration to duct losses has been included in the quota project

- Q: How is FRP ventilation pipe made?

- Coating moldingOn the surface of the mold, a transparent glass paper is fixed on the surface of the bread. When it is fixed, it is coated with a resin coating which has been adjusted. It should be even and not exposed. Then apply a layer of glass cloth and then coat with a resin coating. Each coated with a layer of resin is deposited a layer of glass cloth. The cloth lap to stagger and scraping, the outermost layer of ruibu glass surface should be coated with a layer of resin coating. After reaching the required thickness, and then deposited on the outer surface of the glass paper flatten the light pressure.

- Q: How to install FRP pipe correctly

- Glass tube and carbon steel pipe connection, at present, the most reliable way of connection is indeed onlyOther, such as on-site bonding, because of the two kinds of material is not the same, the quality of bonding is not very stable!

- Q: What kind of material are the flanges and valves on the GRP pipe?

- Construction: glass fiber reinforced plastic can be threaded joints, easy to install, better quality, PVC generally glue adhesive, due to temperature problems, quality is difficult to ensure;

- Q: What epoxy resin is used for anticorrosion of pipeline glass fiber reinforced plastics?

- 3PE has some disadvantages. (1) the bending of the guiding hole and the protruding rock, pebble and gravel in the hole will cause friction and scratch to the relatively soft 3PE corrosion resistant layer. (2) 3PE coating using polyethylene heat shrinkable sleeve joint, the convex part of the concave or lap joint, which makes it easy to travel being scratched or pulled off lead. (2) 3PE corrosion protection layer has a strong electrical shielding, so that the cathodic protection current is difficult to reach the defects of corrosion protection layer, thus causing perforation corrosion.So, from the last century at the beginning of 90s, the United States developed Powercrete (s) Powder Concrete Anticorrosion structure, namely in the bottom of fusion bonded epoxy powder, sprayed with epoxy resin as main film-forming material, and adding a two-component epoxy coating for concrete, polymer concrete curing agent and other inorganic fillers. The coating is tough and wearable and can be used directly in FBE coated pipes to protect the pipe from damage during handling, directional drilling, crossing, etc..

- Q: What is the structure and function of glass fiber reinforced plastic lining?

- The role of FRP lining, corrosion protection, generally attached to the carbon steel container wall, can avoid the use of stainless steel, saving costs. FRP can resist acid and alkali corrosion, PH2-12 or so no problem, but not high temperature, the temperature is higher than 80 degrees, more dangerous, will dissolve.

Send your message to us

Steel Plastic Composite Pipe Fiberglass Winding GRP FRP Pipe Price Fittings Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords