High Quality Fiberglass Mesh Cloth 160g 5x5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass mesh is on the basis of alkali-resistant or C-glass or E-Glass woven fabric, then coated by acrylic acid copolymer liquid,possesses the properties of good alkaline-resistance, high strength, excellent alkali and acid resistance, good cohesion,excellent in coating etc.

2.Fiberglass mesh Main specs:

5mm x 5mm/75g/m2, 90g/m2, 125g/m2, 145g/m2, 160g/m2,etc.

4mm x 4mm/75g/m2, 90g/m2, 110g/m2,125g/m2, 135g/m2, 145g/m2, 160g/m2, etc.

10mm x 10mm/90g/m2, 110g/m2, 125g/m2, 135g/m2. 145g/m2, 150g/m2,160g/m2,etc.

2.85mm x 2.85mm/60g/m2, 75g/m2,etc

plain weave : 10X20mesh/inch:60g/ m2,etc

NO. | Main Specifications | Mesh size | Yarn density | Mass | Tensile strength | |||

warp | weft | warp | weft | warp | weft | |||

1 | 4×4-75g/m2 | 4 | 4 | 48/2 | 200 | 75±3 | 700 | 850 |

2 | 4×4-145g/m2 | 4 | 4 | 134/2 | 240 | 145±5 | 1500 | 1500 |

3 | 4×4-160g/m2 | 4 | 4 | 134/2 | 300 | 160±5 | 1500 | 1650 |

4 | 4×5-110g/m2 | 4 | 5 | 100/2 | 360 | 110±5 | 1100 | 1200 |

5 | 4×5-145g/m2 | 4 | 5 | 134/2 | 300 | 145±5 | 1400 | 1400 |

6 | 4×5-160g/m2 | 4 | 5 | 134/2 | 360 | 160±5 | 1500 | 1600 |

7 | 5×5-125g/m2 | 5 | 5 | 100/2 | 340 | 125±5 | 1100 | 1300 |

8 | 5×5-145g/m2 | 5 | 5 | 134/2 | 360 | 145±5 | 1450 | 1600 |

9 | 5×5-160g/m2 | 5 | 5 | 134/2 | 430 | 160±5 | 1500 | 1700 |

10 | 10×10-90g/m2 | 10 | 10 | 200/2 | 300 | 90±3 | 900 | 1200 |

11 | 10×10-110g/m2 | 10 | 10 | 250/2 | 450 | 110±5 | 1000 | 1400

|

3. Features:

1) Made by C-glass or E-glass fibers woven roving as basis material ,andtreated with acrylic acid copolymer liquid.

2) High in alkali-resistant, strength, widely used in reinforce cement, plastic, gypsum and waterproof.

3) An ideal engineering material for construction field.

4.Storage:

1) Store rolls in a cool, dry location.

2) Store away from the direct contact with ground and concrete

3) Store out of direct sunlight.

5.Application:

1)Wall reinforced material (such as fiberglass wall mesh, GRC wall panels, EPS insulation with the wall board, gypsum board,

bitumen)

2) Reinforced cement products.

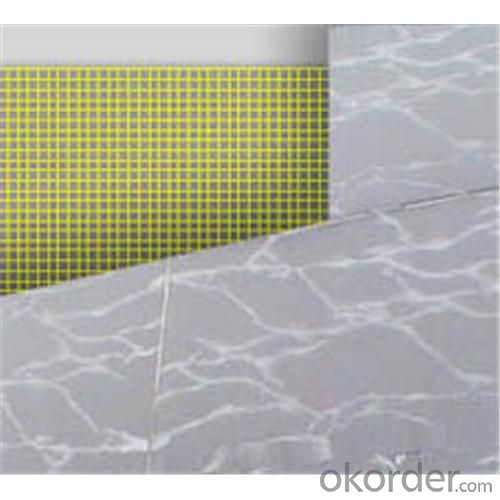

3) Used for Granite, mosaic, marble back mesh et

25

Specifications

alkali-resistance fiberglass mesh

1.Alkaline-resistance

2.Stronge tensile performance

3.Different color available

4.CE ISO

Product Description of alkali-resistance fiberglass mesh

Alkali Resistant fiberglass mesh is made from C-glass, E-glass or AR-glass woven fabric then coated byacrylic acid copolymer liquid. This alkali-resistant mesh has excellent properties including water resistance, flexibility, softness, resistant to aging and attack from breakdown. It is widely used for waterproofing in roofing applications, reinforcement for natural marble, plasterboard, and Exterior Insulation Finishing Systems (EIFS).

Application of alkali-resistance fiberglass mesh

1.Wall reinforced material (such as fiberglass wall mesh, GRC wall panels, EPS insulation with the wall board,

gypsum board, bitumen etc)

2.Reinforced cement products.

3.Used for Granite, mosaic, marble back mesh etc.

4.Fabric waterproof membrane, asphalt roofing.

5.Framework material for einforced plastics, rubber products,.

6.Fire board.

7.Grinding wheel base fabric.

8.Road surface with geogrid

9.Construction caulking tape etc.

Main characteristics of alkali-resistance fiberglass mesh

1.Good chemical stability: Alkali-resistant, acid-resistant, waterproof,, cement erosion-resistant, and other

chemicals' corrosion resistant; and strong resin bonding, soluble in styrene.

2.Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by

Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high

strength, high tensility, light weight.

3.Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world

like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn!

4.Strength retention rate> 90%, elongation <1%, the durability of more than 50 years.

5.Good dimensional stability, stiffness, smoothness an difficult to shrink and deformation, good positioning

property..

6.Good impact resistance and not easy to be teared.

7.Fire resistant, thermal insulation, sound insulation, insulations etc.

Specifications of alkali-resistance fiberglass mesh

1.10x10 mesh, 5x5 mesh, 5x4 mesh, 4x4 mesh, 2.85x2.85 mesh and so on

2.We can produce many specifications and use different packaging according to customers' requests!

- Q: How is fiberglass mesh used?

- The wall should be cleaned before paving and the pits will be patched and leveled

- Q: How to fill the sample size of glass fiber mesh cloth, fill what general specifications

- Therefore, the utility model has the advantages of good alkali resistance, flexibility, and high tensile resistance at warp and weft direction. The utility model can be widely used for heat preservation, water resistance and crack resistance of walls inside and outside buildings. Glass fiber mesh cloth with alkali resistant fiberglass mesh, it uses alkali free glass fiber yarn (the main ingredient is silicate, good chemical stability) by structure leno weaving and special organization, after the anti alkali, heat setting treatment such as reinforcing agent.

- Q: Glass fiber mesh fabric quality, hard and soft for wall, which is better?

- Soft mesh does not depend on the quality of the mesh fabric. Depends on how much the glue is.

- Q: Glass fiber mesh cloth, crack mortar, tiling there is no problem?

- It would be to see how the strength of cement foam insulation board, and you paste the process in order to improve the strength, you can use 1 to 1 fiber cement mortar with latex mixing, can increase the thickness and strength, the cost will be reduced, it can in the brick veneer.

- Q: What harm does fiberglass mesh have to people?

- Into the digestive system, may cause digestive diseases.

- Q: What is the difference between alkali resistant fiberglass mesh and glass fiber mesh fabric?

- Alkali resistant glass fiber mesh cloth on the alkali or alkali glass fiber woven fabrics based coating formed by the alkali, the product of high strength, good bonding, docile, excellent positioning, widely used in the reinforcement of walls, wall insulation, roofing and other aspects

- Q: Self making method and formula of glass fiber mesh cloth shaping glue

- The inner wall heat preservation alkali resistant glass fiber net is made of alkali or alkali free glass fiber mesh cloth as base material, and then modified by coating acrylic ester copolymer liquid. It has the characteristics of light weight, high strength, temperature resistance, alkali resistance, waterproof, corrosion resistance, anti cracking and dimensional stability. It can effectively avoid the surface tension, shrinkage and cracking caused by external forces of the plastering layer, and the light mesh cloth is often used for wall renovation and internal wall insulation.

- Q: What are the fiberglass mesh fabric manufacturers?

- Glass fiber mesh cloth, also called fiberglass mesh, mesh cloth, heat insulation, it can be divided into standard type glass fiber cloth, glass fiber cloth reinforced, flame retardant glass fiber mesh and self-adhesive fiberglass mesh cloth four.

- Q: Can indoor glass fiber mesh cloth be stuck with wall tiles?

- Yes, glass fiber mesh is used for roofing, waterproofing and gypsum, marble, mosaic and other wall or plate reinforcement.

- Q: What is the quota of alkali resistant fiberglass mesh cloth sleeve?

- Method of setting quotas:1.. What project quantity sets what quota, first find the amount of project quantity that needs to be set.2. understand the base price. The price is fixed in artificial materials machinery (+ +, it is note that units) are now consumption quota, consumption is the loss of quota book has made it clear that each of the different material loss, this loss is fixed price price * material.

Send your message to us

High Quality Fiberglass Mesh Cloth 160g 5x5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords