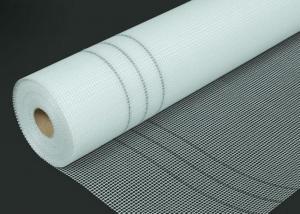

Fiberglass Mesh Cloth with CE Certificate High Quality 55g 5x5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

fiberglass mesh fabric

Fiberglass weave wire mesh:

is mainly alkali-resistant fiberglass fabric, it uses the C /E-glass fiber yarn (main ingredient is a silicate, good chemical stability) through a special weaving technique, then by the anti-alkali and reinforcing agent etc high temperature heat finishing treatments. It's ideal engineering material in construction and decoration industry!

Main characteristics:

1.Good chemical stability: Alkali-resistant, acid-resistant, waterproof, etc.

2.Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28 days later, so that guarantee high strength, high tensility, light weight.

3.Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn!

4.Strength retention rate> 90%, elongation <1%, the durability of more than 50 years.

Application:

1.Wall reinforced material (such as fiberglass wall mesh, GRC wall panels, EPS insulation with the wall board, gypsum board, bitumen etc)

2.Reinforced cement products.

3.Used for Granite, mosaic, marble back mesh etc.

4.Fire board.

5.Grinding wheel base fabric.

6.Road surface with geogrid.

7.Construction caulking tape etc.

Specifications:

1.10x10 mesh, 5x5 mesh, 5x4 mesh, 4x4 mesh, 2.85x2.85 mesh and so on

2.We can produce many specifications and use different packaging according to customers' requests!

Fiberglass mesh specifications |

Roll size | |||

Aperture size(mm) | Weight/square meter | width | length | |

3mm*3mm |

45g-300g/m2 |

0.2m-4m |

30-300m | |

4mm*4mm | ||||

5mm*5mm | ||||

6mm*6mm | ||||

7mm*7mm | ||||

8mm*8mm | ||||

9mm*9mm | ||||

Packing 1: shrink plastic film then woven bags | Packing 2: plastic film then in carton box | |||

- Q: Where are the steel wire mesh and the alkali resistant grid cloth used in the exterior wall insulation?

- The wire mesh is metallic; the mesh fabric is fibrous and the material is different; all are arranged in the

- Q: How to fill the sample size of glass fiber mesh cloth, fill what general specifications

- Mesh size: 5mm*5mm, 4mm*4mm: net weight: 80g---160g/ square meters per roll length: 50m, 100m or 200m.

- Q: Do external insulation with alkali resistant fiberglass mesh cloth, why should the first layer be double or thickened?

- The two layer and the above position can not be reached by human activities, so it is OK to adopt single layer mesh cloth.

- Q: Method for sampling alkali proof glass fiber mesh cloth

- Preparation of polymer mortar must be specially responsible for ensuring the quality of mixing.

- Q: Glass fiber mesh cloth, pure gold pot with what glue out, finished products can be detected, as well as the proportion of glue is how much?

- 1, first of all, from the material, imitation gold pot mesh cloth, its warp is Kim Nabesa, weft is Tonabe Sa, this is called "imitation gold pot" mesh cloth one aspect.2, and then, imitation gold pan mesh cloth looks like the appearance of the gold pan mesh cloth is exactly the same, so it has become imitation gold pot.3, and finally, the quality of imitation gold pan mesh cloth can never be better than the quality of the gold pan mesh cloth, which is also called "imitation gold pot" one of the reasons.

- Q: Self making method and formula of glass fiber mesh cloth shaping glue

- The external wall insulation mesh (glass fiber mesh) with alkali or alkali glass fiber yarn, woven glass fiber mesh to the substrate, and then a new alkali resistant products coated with acrylic copolymer solution after drying into. The product has the advantages of stable structure, high strength, good alkali resistance, corrosion resistance, crack resistance, etc., and the enhancement effect is the best, and the construction is simple and easy to do. Mainly used for cement, gypsum, wall, building and other structures to enhance the internal and external surface, crack prevention, is a new type of building materials insulation project.

- Q: What's the price of fiberglass mesh?

- Alkali resistant glass fiber mesh cloth price range is large, with "Jining wellav" WL-0812 series of products, price fluctuations in the price range of $0.32--5

- Q: What is the difference between alkali resistant fiberglass mesh cloth and high alkali glass fiber mesh cloth?

- The difference lies in the degree of use of alkali resistant glass fiber, at present there are very few domestic high alkali glass fiber products, the difference is in the base. Because the glass itself is not alkali resistant, so in the processing of glass fiber products add alkali resistant components, adding two zirconia, the glass fiber has certain effect on tolerance -OH.The mesh fabric produced with alkali resistant glass fiber is alkali resistant grid cloth, and the others are the same

- Q: Can indoor glass fiber mesh cloth be stuck with wall tiles?

- Yes, glass fiber mesh is used for roofing, waterproofing and gypsum, marble, mosaic and other wall or plate reinforcement.

- Q: Slotted walls, seams, seams, tape, or anti mesh cloth?

- Very simple, you do not have to spend so much money to buy what tape and mesh cloth, is decorated well, to buy the cheapest dacron, remember to not want that kind of chemical fiber, cotton, cotton for a long time to decay. Because in the fiber wall sealed with aging, so. Then through the plaster smooth dry, tore the cloth into strips, glue brush in the gap, and then dried, powder, and you will not crack, affordable, the effect is very good, we give people a lot of friends after use, not see who split over ten years.

Send your message to us

Fiberglass Mesh Cloth with CE Certificate High Quality 55g 5x5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords