Sticker Mule Fiberglass Mesh Adhesive Tape Single Side Waterproof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product specification

Base Material | BOPP Film(Biaxillary Oriented Poly Propylene Film) |

Adhesive Coating | Emulsion Pressure Sensitive Water Base Butyl Acrylic |

Elongation | Less than 170% |

Initial Grab#(ball) | 12~18 |

Holding Force(H) | 10~24 |

Peeling Strength With 180#730 | 4.5~7N/2.5CM |

Adhesive to Self | Less than 90 gms/cm |

Printability | Up to 3 colors as per specifications by Rotogravure Printing. |

Tensile Strength | 25N/CM |

Self Life | More than 36 months |

180 Peel Adhesion | 2N/CM |

2.Usage

Medium & Heavy Carton Sealing.

Gift Wrapping & Decoration.

Bundling & Strapping .

3.Our advangtages

1.BOPP tape, superb tack and adhesion to surface. Strong grip that is ensured because of an excellent adhesive backing.

Quality processing equipment that guarantees consistent quality.

2.Peak performance even under extereme conditions of pressure and temperature. Sticks on all types of surfaces.(paper, plastic, wood,glass,fiber,metal,etc)

3.Consistent quality; 4.On time delivery; 5.Effective and timely communication; 6.Competitive price.

4.About us

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win.

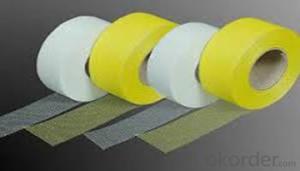

5. product show

6.Our service

• Your inquiry related to our product & price will be replied within 24hours.

• Well-trained & experienced staff are to answer all your inquiries professional in English of course.

• Working time: Mon-Sun 8:30am - 5:30pm (China Time)

• OEM is highly welcomed. We have strong R&D team here to help.

• Your business relationship with us will be confidential to any third party.

• Good after-sale service offered, please get back if you got question.

7.FAQ

How to guarantee our quality?

1). Before produce: send samples for checking.

2). During producing: send photos for producing.

How about Packaging?

1). Can be printed customer's logo on the paper core and cartons.

2). Normal packaging, special packaing as your request, such as individual shrink with logo card, barcode lable, blister card or as request.

- Q: Can packaging tape be used for sealing protective packaging materials like bubble wrap?

- Yes, packaging tape can be used for sealing protective packaging materials like bubble wrap. Packaging tape is designed to provide a strong and secure seal on various types of materials, including bubble wrap. It is commonly used in packaging and shipping industries to ensure that the contents of a package are well-protected and secure during transit. When using packaging tape to seal bubble wrap, it is important to apply the tape along the edges of the bubble wrap to create a tight seal and prevent any potential damage or exposure.

- Q: How do I remove packaging tape without damaging the surface?

- To ensure the surface remains undamaged, adhere to these steps for removing packaging tape: 1. Commence by gently heating the tape with a hairdryer set on low. The heat will cause the adhesive to soften, facilitating easier removal. 2. Employ your fingernail or a plastic scraper to delicately lift one corner of the tape. Exercise caution to avoid employing sharp objects that might leave scratches on the surface. 3. Gradually peel the tape back at a 180-degree angle, applying consistent and uniform pressure. If the tape proves resistant, pause and subject it to additional heat to further soften the adhesive. 4. In the event any residue remains, employ rubbing alcohol or a mild adhesive remover. Apply a small amount to a soft cloth and gently rub the residue until it lifts away. 5. Once the tape and residue have been eliminated, cleanse the surface with a mild soap and water solution to eliminate any remaining adhesive or residue. Always remember to test any cleaning solution on a small, inconspicuous area beforehand to ensure it does not cause damage to the surface.

- Q: What are the different types of packaging tape?

- There are several types of packaging tape available, including clear tape, brown tape, duct tape, masking tape, and double-sided tape. Each type has its own specific use and characteristics, such as transparency, strength, adhesive properties, and thickness.

- Q: Is packaging tape safe for use on delicate surfaces or materials?

- Packaging tape, in general, is not specifically designed for use on delicate surfaces or materials. While it may adhere well to most surfaces, it can potentially cause damage or leave residue on delicate materials such as paper, fabrics, or certain types of paint. To ensure the safety of delicate surfaces or materials, it is advisable to use specialized tapes designed explicitly for delicate applications. These tapes are often referred to as "delicate surface tapes" or "low-tack tapes." They are designed to have a gentle adhesive that can securely hold items together without causing any damage or leaving adhesive residue. Delicate surface tapes are commonly used in the arts and crafts industry, for delicate papers, scrapbooking, or as temporary adhesives for mounting artwork. They are also useful for securing lightweight or fragile items during shipping or packaging. Therefore, while packaging tape can be effective for general purposes, it is not recommended for use on delicate surfaces or materials. It is important to use the appropriate tape for the specific application to protect delicate surfaces and prevent any potential damage or residue.

- Q: Does packaging tape come in different lengths for convenience?

- Packaging tape indeed comes in various lengths for ease of use. Different packaging tasks can be accommodated with packaging tape of different lengths. The commonly found lengths for packaging tape are 55 yards (50 meters) and 110 yards (100 meters). These lengths are specifically chosen to address diverse packaging needs and to ensure that there is an ample amount of tape to securely seal multiple packages without any shortage. Furthermore, the availability of different lengths provides the flexibility of selecting the most appropriate quantity of tape for individual packaging requirements, ensuring both convenience and cost-effectiveness.

- Q: Can packaging tape be used for sealing cosmetic or beauty products?

- Sealing cosmetic or beauty products with packaging tape is indeed possible. However, it is crucial to consider the suitability of the chosen tape for the product's specific requirements. If the cosmetic or beauty item is sensitive to heat or moisture, it is advisable to opt for a specialized tape that offers enhanced protection against these elements. Moreover, ensuring that the selected packaging tape is safe for use on the skin or any part of the body is of utmost importance. Some tapes may contain adhesives or materials that could potentially cause irritation or allergic reactions. Therefore, it is recommended to carefully evaluate the specific needs of the cosmetic or beauty product and select a packaging tape that can effectively and safely meet those requirements.

- Q: What is the difference between acrylic and hot melt packaging tape?

- Acrylic and hot melt packaging tapes are both commonly used for sealing boxes and packages, but they have distinct differences in terms of their adhesive properties and performance. Acrylic packaging tape is known for its clarity and transparency, making it ideal for applications where the appearance of the package is important. It is also resistant to yellowing and aging, ensuring that the tape remains clear and does not become brittle over time. Acrylic tape has a strong initial tack, meaning it adheres quickly to surfaces upon application. However, it may not perform as well in extreme temperatures, as it can lose its adhesive strength when exposed to high heat or cold conditions. On the other hand, hot melt packaging tape is made from a synthetic rubber adhesive that is applied to the tape as a hot liquid. This type of tape offers superior adhesion and bond strength, making it suitable for heavy-duty or challenging packaging tasks. It has excellent resistance to temperature changes, maintaining its adhesive properties even in extreme conditions. Hot melt tape is also known for its quick and easy release, making it convenient for high-volume packaging operations. In summary, while both acrylic and hot melt packaging tapes are effective for sealing boxes, they have different strengths and weaknesses. Acrylic tape is best for applications where clarity, aging resistance, and initial tack are priorities. Hot melt tape, on the other hand, excels in terms of adhesion strength, temperature resistance, and ease of use. Ultimately, the choice between the two depends on the specific requirements and conditions of the packaging task at hand.

- Q: Is packaging tape easy to tear?

- Indeed, packaging tape is typically quite simple to tear. Numerous packaging tapes are specifically crafted to be torn effortlessly by hand, eliminating the need for scissors or any other tools. Typically, the tape incorporates perforated lines or a slightly thinner portion that enables straightforward tearing. This feature renders it convenient for swiftly sealing or opening packages without encountering any inconvenience. Nonetheless, the ease of tearing may differ based on the particular brand and caliber of the packaging tape.

- Q: Can packaging tape be used for sealing construction or building materials?

- Indeed, packaging tape possesses the capability to seal construction or building materials. Although it lacks the endurance and strength found in specialized construction tapes, packaging tape can serve as a temporary or expedient remedy for sealing materials like cardboard, plastic sheets, or lightweight panels. It is suitable for fastening interim covers, affixing protective layers, or keeping materials secure throughout construction or renovation endeavors. Nevertheless, for extended or demanding applications, it is advisable to opt for tapes explicitly engineered for construction, as they exhibit superior resistance against weather, UV rays, and possess enhanced adhesive properties.

- Q: Is packaging tape safe to use on plastic hangers?

- Packaging tape is generally safe for use on plastic hangers, as it is designed to securely hold items together and can adhere well to various surfaces, including plastic. However, it is important to take into account the type of plastic hanger and its intended purpose. While packaging tape may be suitable for temporarily securing clothes on a plastic hanger, it could potentially leave residue or cause damage if left for an extended period. It is recommended to test a small area of the hanger first to ensure that the tape does not cause any harm or leave marks. Moreover, if the plastic hanger is used for displaying or storing delicate or valuable clothing, it might be better to consider gentle alternatives such as fabric-friendly tape or non-adhesive hanger attachments.

Send your message to us

Sticker Mule Fiberglass Mesh Adhesive Tape Single Side Waterproof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords