Fiberglass Insect Screening Mesh 18*16/115g Factory Direct Sale

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 M2 m²

- Supply Capability:

- 20000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

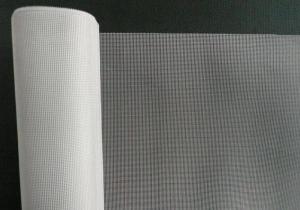

Introduction of Factory Direct Sale Fiberglass Insect Screening Mesh:

The Best Quality Fiberglass Insect is made of glass fiber by the means of single filament plastic coating process, plain weaving and thermal finalizing. It is the best protective product to keep out a wide range of pests and insects. It is widely used for air exchange and insects proof in high-grade office building, residence and various buildings. It is also used for field, garden, vegetable shed, ect.

Factory Direct Sale Fiberglass Insect Screening Mesh

Fiberglass Plain Insect Screen is made of glass fiber by the means of filamentship plastic-coating process ,plain weaving and good temperature-fixing

The product has charateristics of adumbral and good aeration,eroding resistant and fireproofing,easy cleaning and flexible,long service life and feels soft etc,which is also with high tensile strength.Fiberglass Insect Screen is an ideal material used in industrial and agricultural building to prevent from fly,mosquito and small insect etc.

Specifications of Factory Direct Sale Fiberglass Insect Screening Mesh:

1.Size: 18x16mesh, 18x14mesh, 18x18mesh,14x14mesh

2.Roll width: 60cm—1830cm;

3.Roll length: 30m;50m,or as per requirements of custoumers

4.Color: black , gray , gray and white color, coffee etc;

5.Packing: 6rolls/carton, 8rolls/carton, 10rolls/ctn or according to requirements of customers.

Density (Counts/25mm) | Yarn diameter (mm) | Treated Woven Mass G/m2 | Woven structure | |

Warp | Weft | |||

18 | 16 | 0.28 | 115-135 | Plain |

18 | 14 | 0.28 | 115-135 | Plain |

Width(cm):61,71,76,81,91,100,122,152,160,183,200,220,240, 270, 300

Length(m):30,50,100,183, 250, 300

Other special sizes are available according to customer’s requirement

Package of Best Quality Fiberglass Insect Mesh:

Fiberglass insect screen is wrapped on a paper tube, put in a plastic bag, then to be packed in a carton.

- Q: What are the types of ground wire of copper braid

- According to the nominal cross section integral 2-1200 square, with 2 squares copper braided belt as an example, unit root * * * set of single line diameter,Reference width * thickness2 square copper braid =24*5*1/0.15=5.0*1.0Different cross-sectional area of the copper braid parameters are not the same.

- Q: Handmade wire mesh video

- Do you have a web site to find a woven bag manufacturers easy to find

- Q: How to weave a web of hares

- Commonly used to capture the network length of 20 meters, or 30 meters, or 50 meters, and less investment, about 2 yuan per meter. Easy to use for the layout of the terrain and the use of the network to capture the rabbit investment.

- Q: Metal mesh knitting machine where the parts are sold, in urgent need of

- Then look for knitting machine parts inside, there are a lot of business contact, you can call, or network communication, ask any website verified enterprises are credible, so it is easy to find should be at the top

- Q: 100 square copper braided wire can carry much current ah

- Have a great relationship with the current temperature and copper, a copper wire GB ampacity tables, you can see. 100 square copper braided wire at around 35 degrees, carrying capacity of about 400A, hoping to help you

- Q: How to knit a sweater from top to bottom

- I'll give you the details of the process: first, the number of the collar of the needle, the collar is woven, the collar is divided into three parts, I said the number of needles, one of the front and back of the film, a total of two sleeves, and then there are 4 ribs. I have a picture of the back to see you, I understand. The number of needles in the 4 tendons is accounted for in these 4 parts,

- Q: Why the metal box door and the metal box must be made of braided copper wire

- Product introductionCopper wire, copper braid wire, copper wire, copper wire, stainless steel wire brush, metal wire mesh. Filter wire mesh, conductive tape, electrical soft copper connections, expansion joints, soft copper connections, copper braid soft connection, conductive busbar, copper aluminum transition soft connection, and can be manufactured according to user requirements.

- Q: HDMI line is woven nets play a role? Hope answer

- Ordinary woven wire is made of chemical fiber line, that is, to protect the inside of the wire bending and prevent external hard wire scratch. Followed by beauty.

- Q: Does anyone know how the red rope is woven? Thank you for your advice!!

- 3, after the good, to the short axis of the winding4, repeat 2, 3 steps, until the desired length5, then a double link or snake knot fixed, and then make a button the lift through the circle, tighten, the formation of a buckle; in addition, the local file will form a circle, take the long side when the stables, from the circle on the edge of tight, so again, be able to change the coding bracelet, their length adjustment, finally at the end of the long side of the head directly with wear in tighten it. Second: take the red rope, one end of the red rope circle into a circle, leaving a nod, picked up on the other side of the head through the circle, to wear more than two times, tighten, form a button, the button called Acacia buckle. Can squeeze a few more on the rope, have their own design, like a good.

- Q: How to protect the nylon sheath

- This material can only be in a certain period of time and conditions will have waterproof effect, and there is a certain relationship with the water temperature, and the properties of nylon sheath is better, there will be no problem. 2, the nylon sheath waterproofing agent treatment, after treatment, the nylon sheath increased some special features of the building used for longer periods of time by the number of brush, this function will be lost, this time to re processing, to ensure its performance.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1987 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Fiberglass Insect Screening Mesh 18*16/115g Factory Direct Sale

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 M2 m²

- Supply Capability:

- 20000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords