Famous Tinplate For Bottle Caps, DR, MR Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Usage

Tinplate is widely used for making all types of containers, containing industrial usage such as paint can, oil can, aerosol cans etc., and food cans like milk powder cans, tomato paste can, dry food cans etc.

2. Quality

As a state owned company and a large tinplate supplier in China, our tinplate quality ranks 1st level in China, similar to Bao Steel, Posco etc.

3. Specification

standard: GB/T2520, JIS G3303, DIN EN10202

Material: MR /SPCC

Thickness available: 0.16-0.50MM

Width available: 600~1050MM

Temper grade: T1 – DR8

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g and others

Package: sea worthy export package.

Applications: Tin can for chemicals & paint cans, industrial cans, food cans

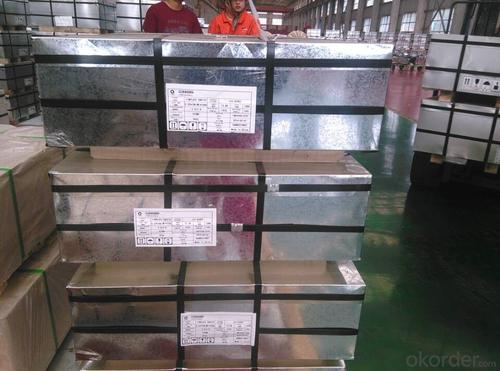

4. Our factory photo & equipments

5. Our Markets:

now our tinplate has been sold to more than 50 countries, including Europe country, Gulf Area, South American, South Afric etc.

6. Our Overseas Wareouses:

Furthermore, in the year 2014, we have more than 10 overseas warehouses all over the word, located in KSA, UAE, Oman, Russia, Kuwait, Qatar, Oman, Chile, Brazil etc.

7. FAQ

a. what's the annual output?

about 500,000 tons per year.

b. where's the raw matrial from?

our hot rolled coil is purchased from Capital Steel and other state owned mill, with quite good quality.

c. how long is the delivery time?

normally for SPCC about 45~55 days, while 65~75 days for MR material

d. how to control the quality during production process?

inside our workshop, we have MES syestem. It realizes the optimization of the production procedure in the workshop. It could record each step of the whole production procedures, and if some problem appears, factory could easily found and take action, it’s quite helpful to monitor and control the quality.

- Q: What are the different ways to open tinplate cans?

- There are several different ways to open tinplate cans. The most common method is to use a can opener, which is a handheld device specifically designed for this purpose. Another option is to use a knife or a pair of scissors to carefully pierce and cut open the lid. In some cases, cans may have pull tabs or easy-open lids that can be peeled back without the need for any tools. Additionally, there are electric can openers available that automate the process for convenience.

- Q: What are the different methods of joining tinplate components together?

- There are several methods for joining tinplate components together. Some common techniques include soldering, spot welding, adhesive bonding, and mechanical fastening. Each method has its advantages and is chosen based on factors such as the complexity of the assembly, desired strength and durability, and cost considerations.

- Q: What are the main applications of tinplate in the pharmaceutical industry?

- Tinplate is primarily used in the pharmaceutical industry for packaging purposes. Its main applications include the production of tinplate cans, containers, and closures. These tinplate packaging solutions provide a reliable and durable barrier against moisture, light, and oxygen, ensuring the protection and preservation of pharmaceutical products. Additionally, tinplate is also used for labeling and promotional purposes due to its excellent printability and aesthetic appeal.

- Q: The difference between a matte tin plate and a bright tin plate

- Tin ma:Rough processing refers to electroplating in the original plate after passivation, not by tin matte soft melting process. It has a unique and elegant silver gray surface, and it has high adhesiveness after coating. It is used in bottle caps and printing cans.

- Q: What are the main applications of tinplate in the furniture industry?

- Tinplate is primarily used in the furniture industry for the production of decorative metal trims and accents. It is commonly used for creating ornamental elements on furniture pieces such as drawer handles, cabinet knobs, and decorative trimmings. Tinplate's corrosion resistance and malleability make it a suitable material for adding intricate and elegant details to furniture designs while also providing durability and protection against wear and tear.

- Q: What are the main trends in the tinplate industry?

- The main trends in the tinplate industry include a growing demand for sustainable packaging solutions, increased focus on product innovation and customization, the adoption of advanced technology for production efficiency, and a shift towards lightweight and cost-effective packaging materials. Additionally, there is a rising preference for tinplate packaging in the food and beverage sector due to its durability, versatility, and ability to maintain product quality and freshness.

- Q: How many kinds of tinplate are there? What is the code number?

- Tinplate, also known as tin plated iron, is the common name for tin plated steel sheet. The English abbreviation is SPTE. It is a cold-rolled low carbon steel sheet or strip coated with commercially pure tin on both sides. Tin plays a major role in preventing corrosion and rusting. It will be the steel strength and formability and corrosion resistance of tin soldering, and beautiful appearance with a material, corrosion resistant, non-toxic, high strength and good ductility properties.

- Q: What are the common closure options for tinplate containers?

- Some common closure options for tinplate containers include screw caps, press-on lids, twist-off lids, and pull-tab lids.

- Q: What are the different types of tinplate surface treatments?

- There are several different types of tinplate surface treatments, including electrolytic tinplate (ETP), blackplate, tin-free steel (TFS), and lacquered tinplate.

- Q: Tin cans in what way sterilization good ah

- Meat and pepper 1KG or so is tinplate packaging, it is best to use water bath sterilization pot, water bath spinning the best.

Send your message to us

Famous Tinplate For Bottle Caps, DR, MR Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords