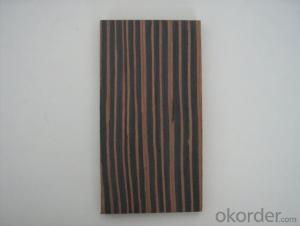

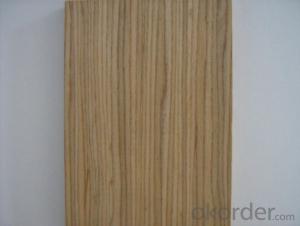

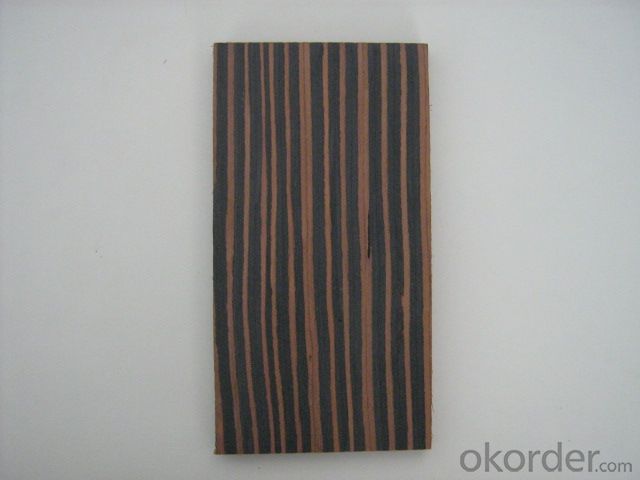

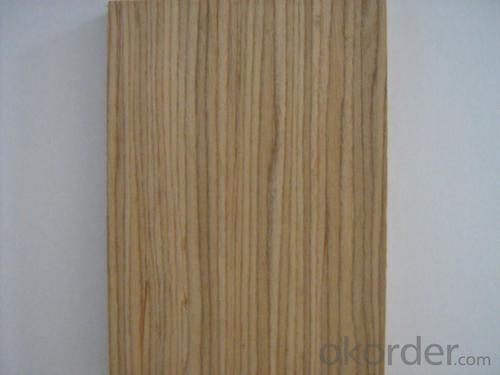

4/3 Plywood Engineered Wood Veneer EV Veneer and Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Engineered Veneer Wood:

Engineered Veneer Unreal Color Wood for Door Skins and Plywood

1.Thickness:0.3mm-0.6mm

2.Grade:furniture,door and panel grade

Specification of Engineered Veneer Wood:

(1)Regular Size: Width640mm*Thickness 0.30-0.6mm *Length 2500mm

(2)Application: Can be used in interior decoration,furniture and music equipments , plywood or MDF , door etc

(3)MOQ: 500m2

(4)Packing:Wood pallet covered with plastic and fixed by iron belt

(5)Terms of payment: TT, LC at sight

(6)Delivery date:within 7—10 days after order confirmed. Your special order is also welcome

Other Information of Engineered Veneer Wood:

Dimension | 2 x 8 feet/2.5mx64cm

| |

Thickness | 0.5mm/0.3mm | |

Grain | quarter cut/crown cut | |

Grade | Good quality | |

Moisture | To be 8%-10% at time of shipment. | |

Quality | Clear grain, uniformity color, no chew silk, no any defect | |

Usage | High grade Furniture, Restaurant and hotel decoration. Decoration board. Be pasted on MDF, Plywood. Other wood product, ect. | |

Package | Wooden pallet packing | |

Quanity fits in container | 20’GP | 35000m2 |

40’GP | 65000m2 | |

40’HQ | 75000m2 | |

MOQ | No requirements or can place a sample order to test our quality. | |

Delivery time | 5-15 days on receipt of deposit. | |

Price terms | EXW, FOB, CIF, CNF. | |

Payment terms | By T/T, 30% for depoait and 70% is paid before shipment or after goods' inspection | |

Process of Engineered Veneer Wood:

Log Selection

EV is generally produced from Chinese Poplar logs, grown locally either by local co-operatives,

or in registered plantation areas. The light natural colour and soft grain definition of Poplar makes it wellsuited to the production of EV. The process of converting timber into EV starts with the selection of logs, following which they are bought to the mill for processing. The timber is trimmed, sawn to length and debarked. The logs are now ready to be peeled.

Peeling of the Logs

The logs are mounted onto a giant lathe. Within minutes the logs are peeled into rotary veneers. This is achieved by pressing a rotating log towards a large blade, thinly peeling a continuous sheet of veneer off the log. The veneer is dried, stacked and then graded. It is now ready to be dyed.

Drying

EV veneers can be dryed to a consistent colour to suit the market requirement. The raw veneer leaves are stacked into a stainless steel cage. Once completely loaded, the stainless steel cage is immersed into a pressurized, heated vat that is filled with water soluble dry. This system ensures that each leaf is given the correct amount of time to allow the dry to completely penetrate each individual leaf of veneer. Once the desired colour has been achieved, the leaves are unloaded from the vat, dried and given a final inspection before going to the gluing stage.

Gluing

The gluing process is critical for the performance of the finished product. A layer of glue goes between each leaf of veneer, to bond the leave of veneer together. Once the stack has been laid up it is then put into a high pressure press to bond the leaves together, creating a large rectangular block.

Slicing of the Block

The block in now ready to be sliced into veneer leaves. Once the block has been produced, it is turned through 90 degrees, to present the end grain, then mounted to the slicing unit. The blade now runs across the end grain of the block, slicing thickness controlled leaves of veneer. The veneer leaves that are produced are approximately 0.4mm thick, and in 2440 x 1220 format. The veneer is now ready to be used as face veneer for Eucalyptus and Poplar core plywood products.

Packing of Engineered Veneer Wood:

- Q: The structure of the plywood at the same time meet two basic principles

- the front panel is called the panel, the back of the table is called the back plate; the core

- Q: Four levels: Principal, First, Second, Third. Commonly used for one, two, three and so on

- partition panel, the board formed by drilling a variety of patterns, the surface spraying a variety of coatings, decorative effect is better

- Q: Judging wood is the standard for plywood

- If you can identify the type of wood used by your own furniture, it will help you identify the true value of the furniture

- Q: How to use building plywood?

- Building plywood is mainly used in outdoor conditions, such as building decoration and concrete template

- Q: How is the current market outlook for plywood?

- Although China plywood has developed rapidly, but still encounter the EU and other importing countries of the anti-dumping complaints

- Q: Multilayer plywood with what method is fixed

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other

- Q: What are the defects of the plywood?

- dead dead knots formed by the dead branches of trees, knots surrounded by the surrounding wood together, or even only part of the length of its cross-section of the length of about 1/4 or less than 1/4 , Texture hard or soft, and sometimes fall off the formation of empty.

- Q: Class III resistant tide plywood class IV tonic resistant plywood

- It is usually made of odd-numbered veneers and The fibers of the adjacent veneers are perpendicularly bonded to each other

- Q: Why is the plywood commonly used in the singular layer

- This is a good understanding of the regardless of the plywood and plywood they are for the sake of their each of them are vertical lines of the

- Q: Decorative veneer veneer plywood features

- Decorative veneer is made of high quality wood by slicing or peeling processing made of thin wood chips.

Send your message to us

4/3 Plywood Engineered Wood Veneer EV Veneer and Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords