Electrolytic Tinplate Sheets for 0.18 Thickness MR Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate Sheets for 0.18 Thickness MR Sheets Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc.

2. Main Features of Electrolytic Tinplate Sheets for 0.18Thickness MR Sheets

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

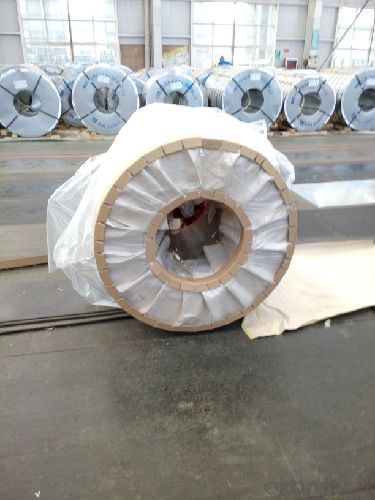

3.Electrolytic Tinplate Sheets for 0.18 Thickness MR Sheets Images

4. Electrolytic Tinplate Sheets for 0.18 Thickness MR Sheets Specification

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.18

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

5.FAQ of Electrolytic Tinplate Sheets for 0.18 Thickness MR Sheets

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

C. What quantity is the minimum order of tinplate?

Usually, the minimum quantity is 25MT. For special case, consult with us.

D. Can it make to be BA or CA for annealing?

Yes, both can do with.

- Q: How is tinplate coated for promotional items?

- Tinplate is typically coated for promotional items using a process called electrolytic tin plating. This involves immersing the tinplate in an electrolyte bath and passing an electric current through it. The electric current causes tin ions to disperse onto the surface of the tinplate, creating a thin layer of tin coating. This coating provides protection against corrosion and enhances the aesthetics of the promotional items.

- Q: What are the main challenges in tinplate warehousing?

- One of the main challenges in tinplate warehousing is the fragile nature of the product. Tinplate is susceptible to scratching, denting, and corrosion, so careful handling and storage procedures are necessary to prevent damage. Additionally, due to its relatively low melting point, tinplate requires proper temperature and humidity control to avoid deformation or discoloration. Lastly, tinplate is often packaged in large and heavy rolls, making logistics and space utilization critical challenges in warehousing operations.

- Q: Can tinplate be welded or soldered?

- Yes, tinplate can be both welded and soldered. Welding involves fusing two pieces of metal together using heat, while soldering involves joining metal components using a lower melting point filler material called solder. Tinplate, which is a thin sheet of steel coated with a layer of tin, can undergo these processes with appropriate techniques and materials.

- Q: How is tinplate protected during transportation and storage?

- Tinplate is protected during transportation and storage through various measures such as applying protective coatings, using packaging materials like wooden crates or pallets, and ensuring proper handling and storage conditions to prevent damage from moisture, corrosion, and physical impact.

- Q: Can tinplate be used for promotional and gift items?

- Yes, tinplate can be used for promotional and gift items. It is a versatile material that can be easily customized and printed on, making it ideal for creating unique and eye-catching promotional merchandise or personalized gifts. Tinplate items such as tin boxes, tin cans, or tin signs can be branded with logos, messages, or designs, making them an excellent choice for promotional and gift purposes.

- Q: Can tinplate be used for packaging household cleaning products?

- Yes, tinplate can be used for packaging household cleaning products. Tinplate is a durable and corrosion-resistant material that provides excellent protection and preservation for various types of products, including household cleaning solutions. It is commonly used in the manufacturing of cans and containers for packaging cleaning products due to its strength, versatility, and ability to maintain product quality.

- Q: What are the safety regulations for tinplate packaging?

- The safety regulations for tinplate packaging vary depending on the specific product being packaged. However, in general, tinplate packaging must meet standards set by regulatory bodies such as the Food and Drug Administration (FDA) or the European Food Safety Authority (EFSA). These regulations typically cover aspects such as the use of safe materials, proper labeling, and ensuring the packaging does not contaminate the product. Additionally, tinplate packaging must often undergo testing for factors such as durability, resistance to corrosion, and overall safety during handling and transportation.

- Q: Can tinplate be used for jewelry and accessories?

- Yes, tinplate can be used for jewelry and accessories. Tinplate is a versatile material that can be easily shaped, engraved, and decorated, making it suitable for creating various types of jewelry and accessories. It is durable, lightweight, and has a metallic appearance, making it an attractive choice for designers and consumers alike. Additionally, tinplate is affordable and readily available, making it a viable option for jewelry and accessory manufacturers.

- Q: What are the main challenges in tinplate coating thickness control?

- The main challenges in tinplate coating thickness control include achieving uniform coating thickness across the entire surface, ensuring consistent adhesion of the coating, minimizing defects such as pinholes or streaks, and dealing with variations in the tinplate surface and composition. Additionally, maintaining precise control over the coating process parameters, such as temperature and speed, is crucial to achieving accurate and desired coating thickness.

- Q: How does tinplate perform in terms of tamper resistance?

- Tinplate performs well in terms of tamper resistance. Its strong and durable nature makes it difficult to tamper with or manipulate without leaving visible signs of tampering. Additionally, tinplate can be sealed tightly, making it hard for unauthorized individuals to access the contents without clear evidence of tampering.

Send your message to us

Electrolytic Tinplate Sheets for 0.18 Thickness MR Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords