Electrolytic Tinplate of Prime Quality for Chemical Use 0.19mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate of Prime Quality for Chemical Use 0.19mm Thickness Description

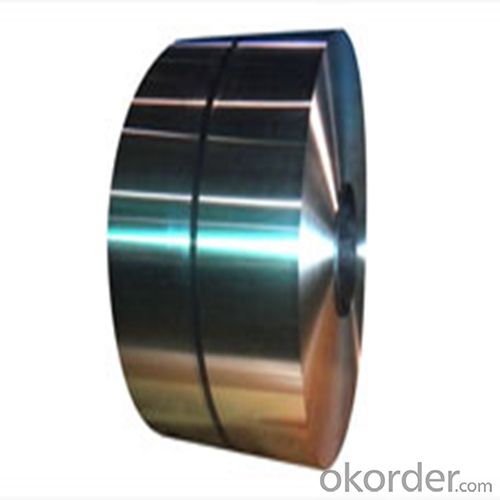

Electrolytic Tinplate is a thin steel sheet coated by tin. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

2.Main Features of the Electrolytic Tinplate of Prime Quality for Chemical Use 0.19mm Thickness

Electrolytic Tinplate undoubtedly enjoys the pride of place as a packaging medium especially for food. It owes its unique position to its "nine layer sandwich structure", each of which contributes to its eminence as a packing material. The steel base of electrolytic tinplate provides the necessary strength and formability for can fabrication. The tin-iron alloy layer provides the bond between the steel and free tin layer. The free tin layer is not only responsible for the attractive bright finish and ease of solderability but is also non-toxic- a factor of vital importance in food packaging!

3.Electrolytic Tinplate of Prime Quality for Chemical Use 0.19mm Thickness Images

4.Electrolytic Tinplate of Prime Quality for Chemical Use 0.19mm Thickness Specification

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR

Thickness:0.19mm

Width: 600mm

Temper: T3

Annealing: BA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish

5.FAQ of Electrolytic Tinplate of Prime Quality for Chemical Use 0.19mm Thickness

- How are the tinplates specified?

The tinplates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q: What are the common thicknesses of tinplate?

- The common thicknesses of tinplate range from 0.13mm to 0.49mm, with some variations depending on specific industry requirements.

- Q: What are the environmental benefits of using tinplate?

- The environmental benefits of using tinplate include its high recyclability rate, reducing waste and the need for new raw materials. Tinplate also provides an effective barrier against oxygen and moisture, helping to extend the shelf life of products and reduce food waste. Additionally, tinplate is lightweight, making it more energy efficient to transport and reducing carbon emissions.

- Q: Can tinplate be shielded?

- With the production of mobile phone shielding materials I know the ocean (Cupronickel), copper, tin phosphor bronze (TIN), these three kinds of material weldability are very good, because the surface of tin!

- Q: How is tinplate recycled?

- Tinplate is recycled through a process called steel recycling. The tin coating on the tinplate is first removed, usually through an acid bath. Then, the steel base is separated from the tin coating. The steel is melted down and used to make new steel products, while the tin coating can be reused for various applications, such as producing new tinplate or other tin-based products.

- Q: What are the benefits of using tinplate for electrical components?

- Using tinplate for electrical components offers several benefits. Firstly, tinplate is corrosion-resistant, which helps to protect the components from moisture and other environmental factors that could lead to damage or malfunction. Secondly, tinplate has excellent conductivity, ensuring efficient and effective electrical flow within the components. Additionally, tinplate is a lightweight and durable material, making it ideal for use in electrical applications. Furthermore, tinplate is easily recyclable, making it a sustainable choice for manufacturers. Overall, utilizing tinplate for electrical components enhances their performance, longevity, and environmental sustainability.

- Q: How is tinplate different from other types of steel?

- Tinplate is different from other types of steel due to its unique coating of tin, which provides superior corrosion resistance, excellent solderability, and enhanced aesthetic appeal.

- Q: How does tinplate compare to plastic packaging in terms of sustainability?

- Tinplate packaging generally has a better environmental sustainability profile compared to plastic packaging. Tinplate is highly recyclable and often contains a significant percentage of recycled content. It has a longer lifespan and can be reused multiple times before recycling. On the other hand, plastic packaging is often made from fossil fuels, non-biodegradable, and has a limited recycling rate. Additionally, plastic waste can persist in the environment for hundreds of years, contributing to pollution and harm to wildlife. Therefore, tinplate packaging is considered a more sustainable option in terms of reducing waste and minimizing environmental impact.

- Q: Can tinplate be used for energy storage applications?

- Yes, tinplate can be used for energy storage applications. Tinplate, which is a thin steel sheet coated with a layer of tin, offers good corrosion resistance and durability, making it suitable for various energy storage purposes. It can be used in the construction of batteries, capacitors, and other energy storage devices. Additionally, tinplate's ability to maintain airtightness and prevent moisture penetration makes it a reliable choice for storing and preserving energy.

- Q: How is tinplate affected by exposure to UV light?

- Tinplate is not significantly affected by exposure to UV light since it is a highly durable material with good resistance to sunlight.

- Q: What are the benefits of using tinplate for roofing?

- One of the main benefits of using tinplate for roofing is its durability and longevity. Tinplate is highly resistant to corrosion and can withstand harsh weather conditions, making it a reliable option for long-term use. Additionally, tinplate is lightweight, making installation easier and more efficient. It also provides excellent insulation, helping to regulate temperature and reduce energy costs. Furthermore, tinplate roofing is aesthetically pleasing, offering a sleek and modern look to any building.

Send your message to us

Electrolytic Tinplate of Prime Quality for Chemical Use 0.19mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords