Ductile iron gate valve ductile iron best quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 111 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

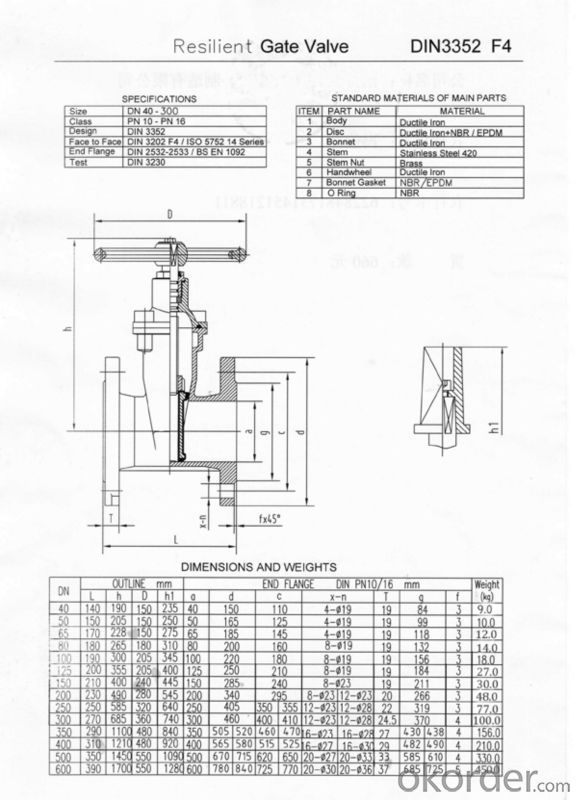

| Standard or Nonstandard: | Standard | Structure: | Gate | Pressure: | Medium Pressure,PN10/PN16/PN25 |

| Power: | Hydraulic | Material: | Casting | Temperature of Media: | Normal Temperature |

| Media: | Gas | Port Size: | DN100 | Place of Origin: | Zhejiang China (Mainland) |

| Model Number: | Z45X | Brand Name: | Kejia | materials: | ductile iron |

Packaging & Delivery

| Packaging Detail: | gate valve packed in plywood cast |

| Delivery Detail: | within 30 days after received the first payment |

Specifications

ductile iron valve ,gate valve,air valve

1.High Quality

2.low Price

3.Fast Delivery.

Ductile iron valve ,gate valve

Summarize

As the traditional valve products is easy to leak and rust, our enterprise has introduced advanced technology

and producted resilient sealing gate valve which can overcome the disadvantages including poor sealing

property, elastic fatigue, easy to rust etc. The resilient gate valve is the updating product, it can reach

favourable sealing effect by using of the compensation effect of micro-transformation, this valve can be

widely used in tap water, sewage, construction, food industry, electric power, pharmacy, metallurgy, light textile,energy system and so on.

Advantages

Flat bottom design

The traditional valve can not be tightly closed if there exists sediment in the valve bottom grooves, our seat

sealing valve owns the flat bottom design which is the same as water pipe line, so there will be no sediment and

no leak any more.

Overall packaged with glue

The valve adopts high-quality rubber coating with inside and outside of the valve, using the domestic first-class rubber vulcanization technology to ensure the accurate size of the vulcanized valve disc, the solid

connection of rubber and ductile iron valve disc provide a good elastic memory.

Corrosion resistant

The valve body is coated with epoxy power to prevent corrosion and rusting of the body, and can be used for

the sewage system.

Ductile cast iron material

All the valve body and valve cover are made of ductile cast iron which improve its strength and hardness

greatly.

Three O-ring sealing

The three O-ring sealing washer (as the shaft sealing)greatly reduced the resistance and leaking.

The precision casting body

The body uses the precision casting which can guarantee the sealing of the valve.

Embedded copper nuts

The nuts and resilient valve are combined closely by embedded connection, so the valve may not be loose or

damaged by vibration caused by water flow.

Suitable for drinking

The inside and outside of the valve is electrostatic sprayed with epoxy which can stop the corrosion and rust, so

the valve can be used in both sewage system and drinking water pipe line.

Light weight

The ductile iron reduce the body weight by 20% to 30%, as it’s lighter than traditional gate valve, it’s easier for

installation and maintenance.

- Q: Which industries need valves?

- Valve application industryValve users in a wide range of industries, can be divided into petroleum, petrochemical, chemical, metallurgy, electricity, water conservancy, urban construction, machinery, coal, food and other. Among them, the machinery and chemical industry users are most concerned about the valve market, and their requirements for the valve is also higher. The largest users of valves are the petrochemical industry, the power sector, the metallurgical sector, the chemical industry and the urban construction sector.Valve application typeIn the application of the types of valves, machinery, metallurgy, petrochemical, chemical, urban construction and other industries, the application of the valve classification of the most. Especially in the machinery industry, all kinds of valves are basically applied. In addition to the mechanical industry, the safety valve is mainly used in chemical industry; butterfly valve is mainly used in petrochemical and metallurgy; diaphragm valve is mainly used in metallurgy, electric power and chemical industry; check valve is mainly used in metallurgy, chemical and petrochemical; valve mainly used in petroleum and chemical industry; the cut-off valve is mainly used in metallurgy, petrochemical, chemical and power sewage; valve is mainly used in petrochemical and chemical industry; the ball valve is mainly used in petroleum, chemical and metallurgy; valve is mainly used in chemical industry, electricity and construction; the valve is mainly used in chemical, metallurgical, power and food; used in petrochemical and metallurgy main plunger valve; plug valves are mainly used in chemical and metallurgical valve; mainly used in petrochemical, chemical and metallurgy; steam traps are mainly used in chemical and petrochemical.

- Q: So how does the valve turn on?

- The handle of the valve is opened along the pipe and perpendicular to the pipe

- Q: Ketem valve relative to other valve companies in the industry what are the advantages?

- The electric actuator built-in servo system, no need to add servo amplifier, input 4-20mA signal and 220V AC power supply can control the operation. Compared with the ordinary electric ball valve, the utility model has the advantages of compact structure, small size, light weight, close distance between the valve seat and the end face flange, less material retention, superior sealing performance, etc..

- Q: How do I open the gas valve?

- 1, the natural gas valve "Shun" pipeline is open, "horizontal" as "off". The following is to open the valve diagram?Turn left and turn right |?2. Attachment: the function of the main facilities of natural gas is:Valve well: a device for installing a valve to control an underground gas pipeline. The building regulation boxes or regional station: the device will be adjusted to the user requirements of medium pressure natural gas pressure. The riser valve: General in the first floor of the building, the kitchen are arranged on the pipe, the vertical pipe used to control all users. Indoor main valve: also known as meter front valve, is the home gas main switch, placed in front of the gas meter, used for natural gas on-off. This valve "opens" the pipe to be opened, "cross" is the pass. Gas meter: IC card intelligent gas meter and user gas consumption measuring device. The front of the stove valve: located in the table, the control valve of gas stove, gas should be closed after the end of time. The IC card is convenient for users to purchase gas use.

- Q: How do you understand the valve Z41X-16?

- This is a standard set, the landlord himself to check the JB/T308 standard, Baidu library, some, and is free to download:JB/T 308-2004 valve type method of preparation clear EditionZ = gate valve4 = connection: flange1 = structural form: open rod single gateX = sealing surface material: Rubber16 = nominal pressure: 1.6MPa16 there is no letter behind it indicates that the body is made of cast iron

- Q: What do you mean by the 16 bit coding of the valve type?

- What kind of coding do you mean? Valve type? Stress? Do you have these?Profit ZF43Y-250C-DN50.. Do you mean this one? ZF43Y valve type. Flat gate valve250C. Refers to the 250 pressure, C is carbon steel, DN50 refers to the caliber of the valve specificationsI hope you mean this one

- Q: What's the sewage treatment valve with?

- Sewage treatment system valve requirements are not high, the use of butterfly valve is one of the most cost-effective.

- Q: How to better maintain the valve?

- We should keep the valve cleanWe should regularly check and maintain the integrity of the valve the other components. As a fixed hand wheel nut fell off, to be filled and can not manage, otherwise it will grind the valve stem upper garden square, gradually lost with the reliability, and even can not startWe do not rely on the valve support other heavy objects, do not stand in the valveThe stem, especially the threaded part, to regular cleaning, the dust has been soiled should be replaced with a new lubricant, because the dust contains hard debris, easy to wear thread and stem surface, affect the service life

- Q: What kind of valves are best used for sand drain valves?

- Looking at the domestic sand discharge conditions, the more commonly used plate valve and butterfly valve these two, but generally reflect the service life is not long, it will not be long before the sand leakage, the need for regular maintenance, low efficiency, affecting production. In recent years, the industry has also appeared in various kinds of new type of valve, take little effect, but also has a valve using the excellent response, talent shows itself, long service life, no maintenance, model for the special valve industry Yu powder FQD672 and FQD643,It is understood that the valve industry has been to focus on Yu powder (sand) on body condition, especially the delivery of viscous pneumatic conveying system, special valve type FQD672 and type FQD643 powder successfully developed specifically for the design of sand material conditions, erosion resistant, anti adhesive seal design, automatic compensation, to ensure zero leakage absolutely, efficient and longevity, is applied to the resin sand casting industry (coarse sand) sand core shape of the high-speed exhaust conditions, you can try to understand Baidu......

- Q: What's the valve as a unit?

- Business now there are many valve manufacturers, with the rapid expansion of SMEs, SMEs are more ~!

Send your message to us

Ductile iron gate valve ductile iron best quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 111 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords