DR Temper Tinplate for Metal Can Making, Top Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Usage

Tinplate is widely used for making all types of containers, containing industrial usage such as paint can, oil can, aerosol cans etc., and food cans like milk powder cans, tomato paste can, dry food cans etc.

2. Quality

As a state owned company and a large tinplate supplier in China, our tinplate quality ranks 1st level in China, similar to Bao Steel, Posco etc.

3. Specification

Standard | GB/T2520, JIS G3303, DIN EN10202 |

Material | MR /SPCC |

Thickness available | 0.16-0.50MM |

Width available | 600~1050MM |

Temper grade | T1 – DR8 |

Tin coating | ordinary 2.8g/2.8g, 5.6g/5.6g and others |

Package | sea worthy export package |

Applications | Tin can for chemicals & paint cans, industrial cans, food cans |

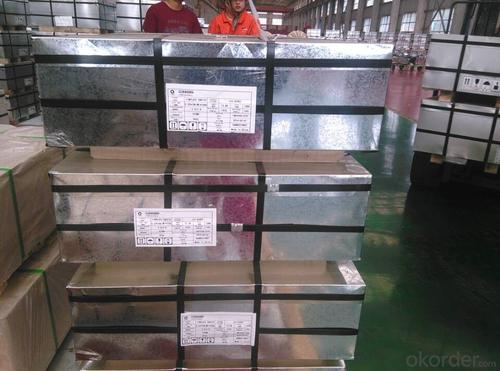

4. Our factory photo & equipments

5. Our Overseas Wareouses:

Furthermore, in the year 2014, we have more than 10 overseas warehouses all over the word, located in KSA, UAE, Oman, Russia, Kuwait, Qatar, Oman, Chile, Brazil etc.

6. FAQ

a. What’s the price difference between SPCC & MR?

Our MR is about usd 15~20/mt higher than SPCC; b. What’s the difference between SPCC & MR

They have difference element content, MR is better than SPCC in anti-rust and deep drawing.

Steel | C | Si | Mn | P | S | Cu | Others |

MR | ≤0.09 | ≤0.03 | ≤0.35 | ≤0.02 | ≤0.025 | ≤0.1 | ≤0.35 |

SPCC | ≤0.12 | ≤0.5 | ≤0.035 | ≤0.025 |

c. What production standards you accept?

We could accept production standards upon our customer request, such as JISG 3303, DIN EN10202, GB/T2520 etc. Our tinplate could meet these standards.

d. If we want to place order, is there any requirement about the booking time?

We need to purchase raw material in advance. Around date 20 per month our production plan will be finalized. So it’s better if customer could place order before date 20 per month, otherwise the delivery time will delay one month.

- Q: What are the main properties of tinplate?

- Tinplate is a type of steel coated with a thin layer of tin, providing it with several key properties. It is highly corrosion-resistant, making it suitable for packaging food and beverages. It also has excellent solderability, allowing for easy joining and sealing of tinplate cans. Additionally, tinplate has good formability, enabling it to be shaped into various container forms. Lastly, its aesthetic appeal and the ability to print on its surface make it an ideal choice for attractive packaging designs.

- Q: What are the main applications of tinplate in the toy industry?

- One of the main applications of tinplate in the toy industry is for creating durable and visually appealing packaging. Tinplate is commonly used to make toy boxes and containers that not only protect the toys but also enhance their overall presentation. Additionally, tinplate is also utilized in manufacturing toy parts and accessories, providing a sturdy and reliable material for various components of toys.

- Q: Tin can bake oven electrical electromagnetic induction principle

- If the bottle seal, then you might be in the vacuum pressure in the bottle the bottle burst, even if there is no heating effect, pressure by the iron pot after heating of the electromagnetic wave will be more and more, the bottle will burst.

- Q: Can tinplate be used for paint cans?

- Yes, tinplate can be used for paint cans. Tinplate is a commonly used material for manufacturing paint cans due to its durability, corrosion resistance, and ability to preserve the quality of the paint inside. It also provides a smooth surface for labeling and branding purposes.

- Q: How does tinplate compare to other packaging materials in terms of brand recognition?

- Tinplate stands out among other packaging materials in terms of brand recognition due to its unique and timeless appeal. Its classic metallic appearance and durability evoke a sense of quality and nostalgia, making it highly recognizable and associated with premium brands. Additionally, tinplate allows for intricate and vibrant designs, ensuring that brands can effectively showcase their logos and visuals, further enhancing brand recognition.

- Q: How can tinplate be identified?

- The quality of tinplate is related to the final use.

- Q: What are the key factors to consider when choosing tinplate for packaging?

- When choosing tinplate for packaging, there are several key factors to consider. These include the quality and durability of the tinplate, its corrosion resistance properties, its compatibility with the packaged product, the desired aesthetic appeal, the cost-effectiveness, and the environmental sustainability of the material. Additionally, factors like the ease of printing, forming, and sealing should also be taken into account to ensure the tinplate meets the specific packaging requirements.

- Q: How is tinplate coated for pharmaceutical packaging?

- Tinplate is commonly coated for pharmaceutical packaging through a process called electrolytic tin coating.

- Q: Can tinplate packaging be used for pharmaceutical products?

- Yes, tinplate packaging can be used for pharmaceutical products. Tinplate is a type of metal packaging that provides excellent protection against moisture, light, and oxygen, making it suitable for preserving the quality and stability of pharmaceutical products. Additionally, tinplate is resistant to corrosion and has high barrier properties, which can help prevent contamination and extend the shelf life of pharmaceutical products.

- Q: How is tinplate made?

- Tinplate is made by coating thin sheets of steel with a layer of tin through a process called electroplating. The steel sheets are first cleaned and prepared, then immersed in an electrolyte bath containing tin salts. When an electric current is passed through the bath, tin ions are attracted to the steel, forming a thin layer of tin on the surface. This tin coating enhances the steel's resistance to corrosion and provides a shiny and attractive finish.

Send your message to us

DR Temper Tinplate for Metal Can Making, Top Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords