Tamperproof Double Sided Tissue Tape 100 Micron SGS & ISO9001

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

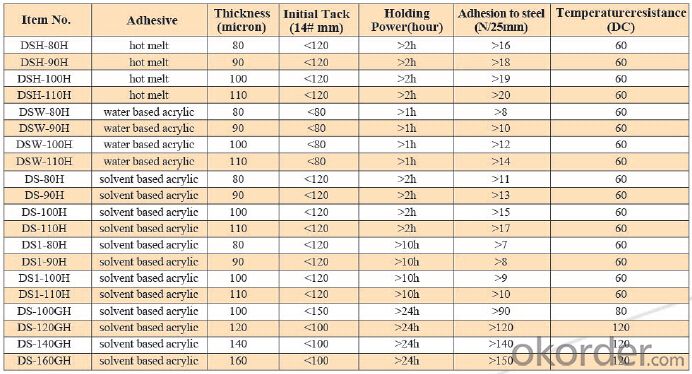

Typical Physical Reports of Double Sided Tissue Tape

Description

The Double Sided Tissue Tape is of tissue as the carrier, coating with hot melt adhesive, water based acrylic, solvent based acrylic. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

Application

General purpose of Double Sided Tissue Tape: widely used for bonding, fixing for leather, foam, sponge, garment, shoe, luggage, plastic, paper splicing and stationery.

Packaging & Delivery

Packaging Detail:

Log Roll: Length 1000mm; width: 1050mm, 1260mm, 1040mm..

Cut Roll: As per customer’s requirements

Delivery Detail: within 7-15 working days after receiving your deposit

Service

Sample of Double Sided Tissue Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service

Well-trained & experienced sales representative are ready to answer you.

About us

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Welcome to contact us and visit the factory!

- Q: Can packaging tape be used for sealing cloth or fabric items?

- Packaging tape has the capability of sealing cloth or fabric items. Its design ensures strength and adhesive properties, making it efficient for securing and sealing different materials, such as cloth and fabric. When it comes to packages containing cloth or fabric items, packaging tape becomes particularly handy as it ensures a secure closure that prevents any potential damage or loss during transportation or storage. Furthermore, the transparency of packaging tape allows for effortless identification of the contents while maintaining the overall appearance of the cloth or fabric item intact.

- Q: Is packaging tape suitable for sealing heavy boxes?

- Yes, packaging tape is suitable for sealing heavy boxes. Packaging tape is designed to provide a strong and secure seal for boxes of various sizes and weights. It is made from durable materials such as polypropylene or reinforced paper, which adds strength to the tape and ensures that it can handle the weight and pressure of heavy boxes. Additionally, packaging tape usually has a strong adhesive that bonds well with cardboard surfaces, ensuring a tight seal that can withstand the rigors of transportation and handling. However, it is recommended to use multiple strips of tape to reinforce the seal on heavy boxes for added security.

- Q: Can packaging tape be used for sealing cardboard boxes?

- Yes, packaging tape is commonly used for sealing cardboard boxes as it provides a strong and secure bond.

- Q: What course of packing and cartons do we use for our company?

- The raw material accounts for all the materials in the inventory of the enterprise, including the planned costs and actual costs of raw materials and main materials, auxiliary materials, purchased semi-finished products, repair parts, packaging materials, fuels, etc..

- Q: How do I prevent packaging tape from becoming brittle?

- In order to avoid packaging tape from becoming brittle, there are several steps that can be taken: 1. Proper storage is key. Ensure that the packaging tape is stored in a cool and dry location, away from direct sunlight. Extreme temperature fluctuations can lead to tape brittleness, so it is important to maintain a consistent environment to prolong its lifespan. 2. Excessive tension should be avoided when applying the tape. It is best not to stretch the tape too tightly or apply excessive pressure, as this can strain the adhesive and cause it to lose flexibility, resulting in brittleness. 3. Selecting the appropriate tape is essential. Different types of packaging tapes have varying levels of durability. Depending on your specific needs, choose a tape that is specifically designed for heavy-duty or long-term use. These tapes often have stronger adhesives and materials that are less prone to becoming brittle. 4. Handle the tape with care during use. It is important to handle the tape gently to avoid unnecessary stress. Pulling or tugging forcefully on the tape can weaken its structure and lead to brittleness. 5. Replace old tape when necessary. If you notice that your packaging tape has started to become brittle or lose its adhesive strength, it is best to replace it with fresh tape. Using old and brittle tape may compromise the security of your packaging, increasing the risk of it breaking or coming undone during transit. By following these preventive measures, you can help maintain the flexibility and durability of your packaging tape, ensuring it remains reliable for your packaging needs.

- Q: Can packaging tape be used for sealing industrial or manufacturing goods?

- Yes, packaging tape can be used for sealing industrial or manufacturing goods. Packaging tape is designed to secure and seal packages, boxes, and cartons, making it suitable for a wide range of applications. It is commonly used in various industries, including manufacturing, to ensure the safe transportation and storage of goods. Packaging tape provides a strong and durable seal, preventing the contents from spilling, getting damaged, or being exposed to external factors such as moisture or dust. Additionally, it offers easy application and removal, making it convenient for sealing large quantities of industrial or manufacturing goods efficiently.

- Q: How does packaging tape perform when exposed to chemicals or solvents?

- The performance of packaging tape can vary depending on the type of tape and the chemicals or solvents it is exposed to. Generally, packaging tapes are designed to resist common household chemicals like cleaning agents, oils, and water-based solvents. These tapes are typically made from materials with excellent chemical resistance properties, such as polypropylene or PVC. As a result, they can maintain their adhesion and integrity even when exposed to moderate amounts of chemicals or solvents. However, it is important to be aware that certain aggressive chemicals or solvents, like strong acids or organic solvents, may have a negative impact on the tape's performance. These highly corrosive substances can cause the tape to degrade, lose its adhesive properties, or dissolve completely. To ensure optimal performance, it is recommended to consult the manufacturer's information on chemical resistance properties for the specific packaging tape being used. They can provide guidance on whether the tape is suitable for different types of chemicals or solvents. Additionally, conducting small-scale tests or trials to assess the tape's performance when exposed to specific chemicals or solvents before using it for critical packaging applications is advisable. In conclusion, packaging tape generally performs well when exposed to common household chemicals or solvents. However, its performance may be compromised when exposed to aggressive or corrosive substances. It is important to refer to the manufacturer's guidelines and conduct tests, if necessary, to ensure that the tape is suitable for the specific chemical or solvent it will be exposed to.

- Q: Are there any eco-friendly options for packaging tape?

- In today's market, there are various eco-friendly options for packaging tape. Typically, traditional packaging tapes are made from plastic materials like polypropylene or PVC, which are harmful to the environment and not biodegradable. However, there have been developments in creating eco-friendly alternatives to tackle this issue. Some of these options include: 1. Packaging tape made from paper: These tapes are crafted from renewable resources like paper and natural adhesives. They are both biodegradable and compostable, making them a sustainable choice for packaging requirements. 2. Gummed paper tape, also known as water-activated tape: This type of tape is made from paper and requires water to activate the adhesive. It forms a strong bond when applied to boxes and provides tamper-proof sealing. Additionally, water-activated tape is biodegradable and can be recycled along with the packaging it is used on. 3. Biodegradable and compostable tape: These tapes are manufactured using plant-based materials such as cellulose or polylactic acid (PLA). They are designed to naturally break down over time, minimizing their impact on the environment. Some options are certified as compostable, meaning they can be added to compost piles or sent to composting facilities. 4. Recycled plastic tape: Although traditional plastic tapes are not environmentally friendly, there are recycled plastic tape options available in the market. These tapes are produced using recycled plastic materials, reducing the demand for new plastic and promoting a circular economy. When searching for eco-friendly packaging tape, it is crucial to consider certifications such as the Forest Stewardship Council (FSC) for paper-based tapes or the Biodegradable Products Institute (BPI) certification for compostable tapes. By opting for these alternatives, individuals and businesses can minimize their environmental impact and contribute to a more sustainable future.

- Q: Can packaging tape be used for sealing plastic or poly bags?

- Certainly! Packaging tape is capable of sealing plastic or poly bags. Its design is focused on creating a strong and secure seal on different surfaces, such as plastic and poly bags. By utilizing an adhesive backing, the tape effectively sticks to the plastic material, guaranteeing a tightly sealed bag. Nevertheless, it is crucial to consider that there are various types of packaging tape accessible. To achieve optimal performance and a durable seal, it is advisable to select a tape that is explicitly designed for sealing plastic or poly bags.

- Q: Is the insulating tape waterproof?

- There are special waterproof adhesive tape and insulating tape. It's not the same.General electrician work when two are used.Black wove feeling is insulated

Send your message to us

Tamperproof Double Sided Tissue Tape 100 Micron SGS & ISO9001

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords