Double-pillar Heavy-duty Construction Hoist /Material Hoist /Industrial Hoist

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

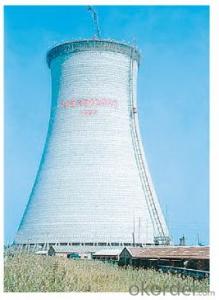

Our SC Construction Hoist is an industrial engineering elevator driven with pinion and rack, used for vertical transportation of materials, people and other heavy items, applicable to highrise building construction, storehouse, port, dock, tower, chimney and so on. The construction hoist is made up of either one or two cars (cages) which travel vertically along stacked mast tower sections. The mast sections are attached to the structure or building every certain distance for added stability. For precisely controlled travel along the mast sections, they use a motorized rack-and-pinion system that climbs the mast sections at various speeds.

This building hoist occupies small space and can transport large and heavy goods; used in department stores, hospitals and parking lots.

Features:

Our construction hoist has many dvantages:

1. Our own systems of production engineering.

2. Production design from the concept to the engineering details.

3. Technical experts with great experience in the sector.

4. Continuous development of new solutions and products adapted to the requirements of our clients.

5. Methodology and project procedure administration in compliance with current guidelines.

6. Extensive worldwide commercial network

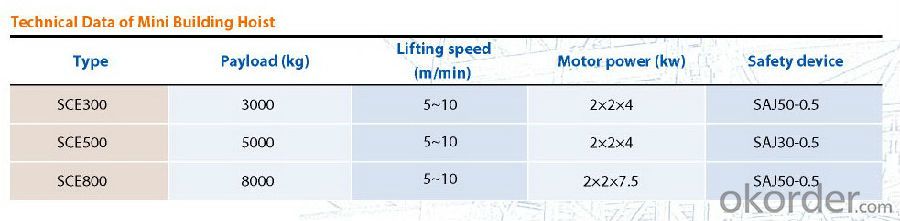

Specifications:

Remark:

1. Recommended cage dimension (LXWXH): 3.0X2.5X5, 5X4X3.2, 3X3X2.4 etc, we can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to your requirements.

3. The mast and the tie-in surface can adopt paint-spray, or hot galvanizeing processing.

- Q: Can a building hoist be utilized to lift more than one object simultaneously?

- <p>Yes, a building hoist can be used to lift multiple objects at once, provided that the combined weight of the objects does not exceed the hoist's maximum load capacity. This is often done by securing all objects to a single lifting point or using a pallet or platform to hold the objects together. It's crucial to ensure that the hoist is rated for the total weight and that the objects are evenly distributed to maintain balance during lifting. Always follow safety guidelines and manufacturer's instructions to prevent accidents.</p>

- Q: This question asks for criteria or factors to consider when selecting the appropriate type of building hoist for a specific construction project.

- <p>Choosing a suitable type of building hoist involves considering several factors: the weight and size of materials to be lifted, the frequency of hoisting, the height of the building, and safety requirements. Assess the load capacity needed, as hoists vary in their lifting capabilities. Consider the hoist's speed and efficiency to ensure it meets the project's timeline. The hoist's size and maneuverability are crucial for fitting within the construction space. Safety features and certifications should be verified to ensure compliance with industry standards. Consulting with hoist manufacturers or rental companies can provide insights into the most suitable hoist for your specific application.</p>

- Q: How long does the construction elevator do a crash test

- For the safety of the crane, the anti-drop safety device must be certified every 1-2 years.

- Q: What are the necessary maintenance tasks and considerations for ensuring the safe and efficient operation of a building hoist?

- <p>The maintenance requirements for a building hoist include regular inspections, lubrication, and checks on all mechanical components. It is crucial to inspect the hoist's cables, pulleys, and brackets for wear and tear. The drive mechanism and safety devices should be tested for proper functioning. Lubrication of moving parts is essential to reduce friction and prevent overheating. Additionally, the electrical system should be checked for any faults or damage. It's important to keep the hoist clean and free of debris to prevent any operational issues. Following the manufacturer's guidelines for maintenance intervals and procedures is vital to ensure the hoist remains safe and efficient.</p>

- Q: The construction of more than many floors must be used for construction elevators

- Elevator drivers must be trained in special safety technology, qualified for examination, and will be on duty. Strict drunken work. The driver must be familiar with the performance, construction, maintenance and maintenance of the elevator, and fill in the mechanical resume and the required reports in time. No inflammable, flammable goods and other sundries shall be piled up in the vicinity of 5m in the construction elevator, and no ditch, pits, or groove shall be dug in this area. The floor feed of the elevator should be set up for protection. When the cage is repaired, if the parts are removed and the weight of the ladder is below the weight, the ladder cage must be locked in the rail. It is strictly forbidden to use the shaft of the construction elevator to support the cable line and other items not related to the elevator. A tower crane or other lifting machine that is built on the same site shall be more than 5m above the elevator and should be properly protected against collision. After the construction elevator is installed, it must be checked and approved by the relevant personnel.

- Q: Is it possible to store lifting equipment in a residential setting such as a home or garage?

- <p>Yes, you can store your lifting equipment in your home or garage, but there are several considerations to keep in mind. Ensure that the space is dry, well-ventilated, and free from extreme temperatures to prevent rust or damage. Store equipment on stable, level surfaces to prevent tipping. Keep equipment away from children and pets for safety. Regularly inspect equipment for wear and tear, and store it properly when not in use to maintain its condition. Always follow the manufacturer's guidelines for storage to ensure the longevity and safety of your equipment.</p>

- Q: This question asks for an explanation of the functioning of hydraulic cylinders in lifting equipment.

- <p>Hydraulic cylinders in lifting equipment operate by converting hydraulic pressure into linear mechanical motion. They consist of a cylinder barrel, a piston, and a piston rod. When pressurized fluid is introduced into the cylinder, it pushes the piston, which in turn moves the piston rod. This movement is what lifts or moves the load. The force exerted by the piston is proportional to the pressure of the fluid and the area of the piston. The cylinder's design allows for controlled and precise lifting, making it ideal for heavy-duty applications where power and control are required.</p>

- Q: Is it possible to utilize building hoists for the transportation of materials and equipment within construction sites?

- <p>Yes, building hoists are commonly used in construction sites to move materials and equipment. They are designed to lift and lower heavy loads vertically, making them ideal for transporting construction materials, tools, and equipment between different floors or levels of a building under construction. This equipment significantly enhances efficiency and safety on construction sites by reducing manual labor and the risk of accidents associated with manual handling of heavy items.</p>

- Q: Is it possible to replace a motor in a building hoist with a hydraulic cylinder?

- <p>While a hydraulic cylinder can provide linear motion and force, it is not a direct substitute for a motor in a building hoist. Hydraulic cylinders are used for lifting and pushing applications, but they lack the variable speed and control that a motor provides. Motors, especially electric ones, offer precise control, variable speed, and efficiency which are critical for hoisting operations. A hydraulic system would require additional components like pumps and valves for control, making it more complex and less energy-efficient compared to an electric motor system. Therefore, a hydraulic cylinder alone is not suitable as a direct replacement for a motor in a building hoist.</p>

- Q: Is it safe to use a lifting device with someone who has no experience with it?

- <p>It is generally not advisable to use a lifting device with someone who is not familiar with it. Lifting devices require proper training and understanding of their operation to ensure safety. Using such equipment without proper knowledge can lead to accidents and injuries. It is crucial to ensure that anyone operating a lifting device has received the necessary training and is familiar with the specific device's safety protocols and operation procedures.</p>

Send your message to us

Double-pillar Heavy-duty Construction Hoist /Material Hoist /Industrial Hoist

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords