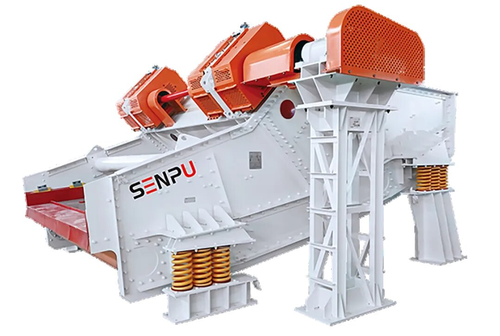

DMS-VB/MDMS-VB linear vibrating screenDMS-VB/MDMS-VB linear vibrating screen

- Supplier:

TANGSHAN ZHONGQING MACHINERY CO.,LTD

TANGSHAN ZHONGQING MACHINERY CO.,LTD

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

The screen is suitable for the dewatering, deintermediation

and classification of lump coal, fine coal or other similar

materials. It offers a series of advantages, including high

capacity, low vibrating noise, screen boxes free maintenance, easy replacement and overhaul of screen plates, satisfactor y vibration reduction, power consumption less than domestic screen with the specifications. It has been granted 2 national patents. Now, 40 sizes ranging from DMS1836-VB/ MDMS1836-VB to DMS 4373-VB/MDMS4373-VB are available.

- Q: How many screens of vibrating screen is better?

- This depends on the requirements of your screening materials, if it is to remove impurities, and with a layer of screen can be, and that is the best, if it is used for grading, it depends on how many points you have,

- Q: How much is the amount of the vibrating screen to be calculated?

- The characteristics of the vibration motor is the lower the speed, the amplitude of the higher vibration motor each turn, the material in the sieve surface was thrown up once, along the parabolic fixed path forward or jump up and down, so that the materials are screening or tap processing. This is also the core technology of vibration screening equipment.Vibration motor models are: JZO, YZU, VB, XVM, YZO, YZS, YZD, TZD, TZDC and so on.

- Q: Selection is good or sub ballast drum sieve shaker.

- Because the material rolls and rolls in the drum, the material stuck in the sieve can be ejected to prevent the screen from clogging. The principle and structure of roller screen sand machine, drum screen and roller screen are almost the same.

- Q: How does the mine vibration sieve do not do?

- The gangue can be rolled several times or rolled for a longer time and can be screened. In addition, the amount of screening is reduced and the slag can be fully shaken and screened on a vibrating screen

- Q: What is the difference between vibrating screen and linear vibrating screen? Should I choose vibrating screen or linear vibrating screen?

- The circular vibrating screen has the advantages of simple structure, convenient disassembly and replacement of the screen surface, and less energy consumed by screening each ton of material.

- Q: What are the requirements for the use of ultrasonic vibrating screens?

- Ultrasonic vibration screen should pay attention to the power supply positive and negative pole, maximum current, screen mesh, screen frame, ultrasonic system installation, material characteristics

- Q: What are the reasons for the small amount of circular vibrating screen?

- Check the wiring mode, whether the line meets the reverse

- Q: What are the damping springs on the vibrating screen?

- There are four kinds of vibration damping springs. Steel wire compression spring, rubber spring, composite spring and rubber air spring.1 、 steel wire compression springCompressed by steel wire, most of which are round, usually equal pitch, steel wire coil and ring in the middle of a certain gap, compression by external force will shrink.2. Rubber springThe rubber spring is made of natural rubber and is a high elastic body. The utility model has the advantages of waterproof, www.zhendong-shai , high temperature resistance, low noise, electric insulation, long service life, low cost, high resilience, etc..3, compound springThe composite spring combines the characteristics of the rubber spring and the steel spiral spring, and the material is also an elastomer combined with the two. Set the advantages of both as one, and also improve the shortcomings of both. The utility model has the advantages of good stability, high load capacity, vibration isolation, noise reduction and the like. The utility model is more suitable for large-scale vibrating equipment in mines, coal, metallurgy and other industries.4 rubber air springRubber air spring, commonly known as rubber air bag. The air is filled in the middle of the inner and outer rubber layers, and the elasticity of the spring is achieved by the compressibility of the air. This spring is seldom used on vibrating equipment.

- Q: How to adjust the amplitude of vibrating screen?Two axle excitation

- In the same way, the frequency converter can also be adjusted (within the allowable range of motors);

- Q: How to use the drilling fluid vibrating screen and how to operate it?

- Amplitude adjustment: first open the hood, a special six angle wrench to loosen the eccentric block fixing bolt, the two ends of the motor with eccentric block angle adjustment, 60%~80% is appropriate, and then fixed bolt.

Send your message to us

DMS-VB/MDMS-VB linear vibrating screenDMS-VB/MDMS-VB linear vibrating screen

- Supplier:

TANGSHAN ZHONGQING MACHINERY CO.,LTD

TANGSHAN ZHONGQING MACHINERY CO.,LTD

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products