DIN7985 DIN965 Machine Screws Cross Recessed ,Pozi Recessed in M3,M4.M5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Product Description of DIN7985 DIN965 Machine Screws Cross Recessed ,Pozi Recessed in M3,M4.M5

we offer DIN7985 ,DIN965 machine screws,Cross or Pozi Flat head machine screw and the matrial we can do is stainess steel , carton steel. it is available for : metal, wood, mdf board, chipboard, Sooter, Skates, Toy, Bicycle, Sporting equipment, building, furniture, automotive, home application and so on.

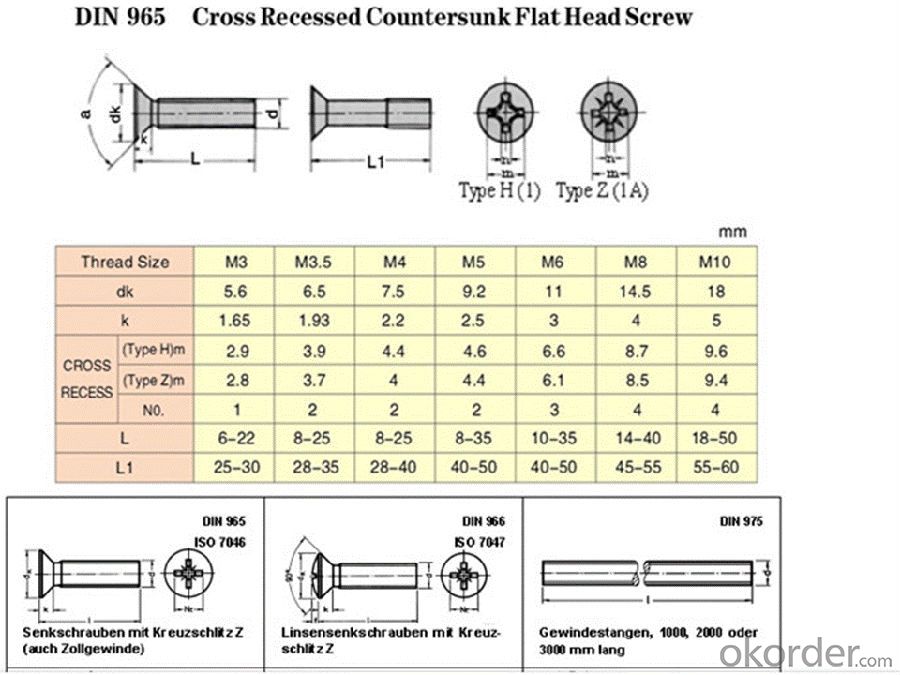

2,The Specification of the DIN7985 DIN965 Machine Screws Cross Recessed ,Pozi Recessed in M3,M4.M5

Brand name | DIN7985 DIN965 Machine Screws Cross Recessed ,Pozi Recessed in M3,M4,M5 |

| Material | carbon steel,stainless steel, |

| Finish | zinc,Nickel plated,black oxide,HDG,dacromet ,etc |

| Standard | ISO,GB,ANSI,BS,DIN or non standard as customize |

| Delivery | within 10 working days upon receipt of 50% deposit |

| Packing | general packing or as your requirment |

| Payment | L/C,T/T,Western Union,Paypal |

| MOQ | 500 pcs |

| Application | mechanical equipment, electronics , furniture home appliances, refrigerating installations,hardware etc |

3, Products Show of DIN7985 DIN965 Machine Screws Cross Recessed ,Pozi Recessed in M3,M4,M5

4,Our products advantages of DIN7985 DIN965 Machine Screws Cross Recessed ,Pozi Recessed in M3,M4.M5 :

1)More than 10 years’export experience in various fasteners

2)The best after-sales service

3)competitive price and high quality

4)short shippment time

5)small order acceptable

6)both standard and non-standard parts are welcome

5,Company information

China National Building Material Group Corporation. CNBM Group ranks 267th of the Globe Fortune top 500 enterprises. Stainless Steel is one of the main products of CNBM. We are specialized in stand and nonstandard fasteners. our products include: bolt,nut,screw,stud,pin,washer .our materials are stainless steel,titanium,steel Zinc,high strength steel,brass ,plastic.Our factory has been built for ten years. Our products are being exported to America, Europe and Asia and ISO90001 quality certification approved.

- Q: Screw hole slip wire how to do?

- The thin copper or cloth wrapped in a screw, and then spin into (emergency, reliability can not be guaranteed)

- Q: What is the meaning of the 8.8 on the screw

- 8.8 is a high-strength screw! 6.8 is the strength of 4.8 is the national standard screws the highest high-strength screws is 12.9 I have seen the best and most exquisite

- Q: Screws are not slopes.

- Yes, the inclination of the object can be seen as a slope This can be seen as a slide, the slide is a slope. The slope is a simple machine. The screw is screwed into a cylindrical slope, the thread on the screw is like the pattern formed in Figure (A), the length of a circle of threads is equivalent to the length of the slope.

- Q: A tightened screwdriver has been damaged, that is, the cross into a round mouth, and now I need to get it out for a new one, is there any way to take it out?

- Screw nail head in the outside with a saw saw a word and then a word screwdriver out ,,, in the inside, with a drill to him to drill

- Q: I would like to know the specifications of the two types of screws models, including length, diameter, diameter and pitch, etc.

- M3 means that the large diameter (external thread is the outer diameter) is 3. Of course with M3 nut, the length of a move does not include the nut. Thread section length is also another specification. M6 indicates a nominal diameter of 6 mm and indicates that it is a standard pitch coarse thread.

- Q: Why a screwdriver can suck the screw

- Because the top of the screwdriver with magnetic junior high school there

- Q: What is the effect of the screw?

- The set screw is mainly used to hold the relative position between the two parts. We call the "head screw", the role of the equivalent of the role of positioning pin.

- Q: This screw ye use, and how to use next to the cover

- This is also the expansion screw. First make a hole, put the plastic into, and then on the top of the screw

- Q: How is the screw produced

- Annealing: the wire heated to the appropriate temperature, to maintain a certain time, and then slowly cooling to adjust the crystal structure, reduce hardness, improve the room temperature processing. Pickling: Remove the oxide film on the surface of the wire and form a layer of phosphate film on the metal surface to reduce the wire drawing and cold pier or forming process. To the required diameter. Practical for some products can be divided into coarse pumping (shelling) and fine pumping two stages. Molding: The wire is forged by cold forging (or hot forging) to achieve the shape and length (or thickness) of the finished product. The finished semi - finished product is rolled or tapped to achieve the desired thread. Practical for the bolt (screw) known as the rolling teeth, teeth known as the rolling teeth, nuts called tapping. Heat treatment: according to the object and the purpose of different different heat treatment can be used. Quenched and tempered steel: quenched high temperature tempering (500-650 ℃) spring steel: quenched after tempering temperature (420-520 ℃) ??carburizing steel: carburizing after quenching and then low temperature tempering (150-250 ℃) low carbon and In the carbon (alloy) steel quenched into martensite, with the tempered temperature rise, the general rule is the strength decreased, while the plasticity, toughness rise. Surface treatment: surface treatment that is through a certain method in the workpiece surface coating process, the purpose is to give the product surface appearance, anti-corrosion effect.

- Q: How did the screw twist?

- maintenance personnel with a large number of screwdriver three five in addition to get the two, he told me that the screwdriver should be used by the small model to the large model too, of course, I did not let you frequently change the screwdriver, but began to have too large Easy to spend, began to use a small easy to spend. Large screwdriver only after the screw has been spent on the stage.

Send your message to us

DIN7985 DIN965 Machine Screws Cross Recessed ,Pozi Recessed in M3,M4.M5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords