DIN Flanged Ball Valve Carbon Steel in good price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 45 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

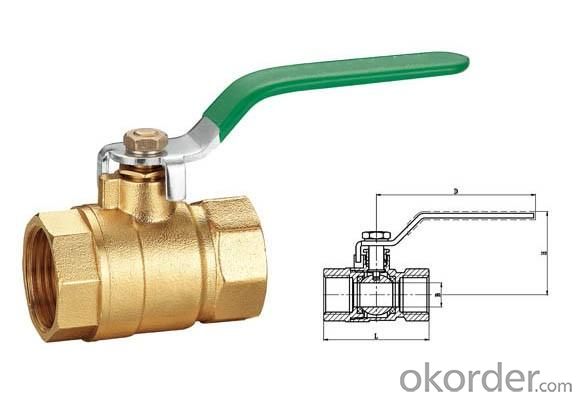

DIN Flanged Ball Valve Stainless Steel & Carbon Steel PN16

1.Investment Casting

2.Medium:Water, Oil ,Gas

3. Seal:PTFE&PPL

DIN Flanged Ball Valve Stainless Steel & Carbon Steel PN16

1. Working pressure: PN16,PN25

2.ISO-5211 Mounting pad for easy automation.

3.Anti-static device.Fire safe design available,

4. Blow-out proof Stem.

5.Suitable media: water, oil, Gas and some corrosive liquids.

6.Investment Casting.

7. Inspection & Testing: API 598.

8.Manual,Gear.Worm wheel, Pneumatic operated avaible.

9.Pneumatic actuator: double action &single action is available.

Manufacturing Process

(01)Mould warehouse-----(02)Wax-----(03)Repaire mould line ----(04)Wax polish ----(05) Tuple trees ----(06)Cast molding----(07)Dry-----(08) Dewaxing ----(09)Wax equipement ----(10) Smelting

- Q: Electric ball valve installation need to pay attention to what?

- 3, valve installation should be detailed understanding of its performance and features; 4, valve installation space to ensure the ease of use, maintenance and repair simple. 5, in order to avoid loose screws, bolts of leakage, before use each fastening screws; 6, in the use of the process should pay attention to the use of medium pressure valve, such as temperature, so as to avoid damage to the valve; 7, such as the valve opening and closing in, should identify the reasons, troubleshooting, no knock, smashing etc. method of forced opening and closing.

- Q: Ball valve specifications 1/2 inches corresponding to DN?

- I know that. 1/2 stands for DN15. 3/4 stands for DN20. Ha ha, unfortunately no points

- Q: The hot water pipe ball valve what brand alone?

- Angle valve is mainly suitable for heating pipes. Usually a connecting point between the hose and the wall that is attached to the wall and attached to the faucet above.

- Q: 1 piece, 2 piece, 3 piece ball valve, which places are used in large quantities?

- Structural features of two piece ball valve:1, opening and closing without friction. This function completely solve the traditional valve because of the friction between the sealing surface and affect the sealing problem.2, top structure. The valve installed on the pipeline can be directly checked and maintained, which can effectively reduce the device parking and reduce the cost.3, single seat design. The utility model eliminates the problem that the medium of the valve in the valve is influenced by the abnormal voltage increase.4 、 low torque design. Special structural design of the valve stem, with only a small hand, the valve can easily open and close.5 wedge sealing structure. Valve is provided by the mechanical force of the valve stem, the ball wedge to the seat and seal, so that the valve sealing is not affected by changes in pipe pressure, in a variety of conditions, sealing performance has a reliable guarantee.6. Self-cleaning structure of sealing surface. When the ball roll off the seat when the fluid in the pipeline along the sealing surface of the sphere into 360 degrees evenly through, not only eliminates the high speed fluid on the seat of local scour, also washed away the sediment on the sealing face, achieve the purpose of cleaning.

- Q: One stainless steel ball, two pieces, three pieces of difference, use

- Structural features of two piece ball valve:1, opening and closing without friction. This function completely solve the traditional valve because of the friction between the sealing surface and affect the sealing problem.2, top structure. The valve installed on the pipeline can be directly checked and maintained, which can effectively reduce the device parking and reduce the cost.3, single seat design. The utility model eliminates the problem that the medium of the valve in the valve is influenced by the abnormal voltage increase.4 、 low torque design. Special structural design of the valve stem, with only a small hand, the valve can easily open and close.5 wedge sealing structure. Valve is provided by the mechanical force of the valve stem, the ball wedge to the seat and seal, so that the valve sealing is not affected by changes in pipe pressure, in a variety of conditions, sealing performance has a reliable guarantee.6. Self-cleaning structure of sealing surface. When the ball roll off the seat when the fluid in the pipeline along the sealing surface of the sphere into 360 degrees evenly through, not only eliminates the high speed fluid on the seat of local scour, also washed away the sediment on the sealing face, achieve the purpose of cleaning.

- Q: The valve nominal 1/2, 3/4 is how much?

- 1/2 equivalent to the national standard of 15mm, 3/4 equivalent to GB 20mm. That is, DN15 and DN20

- Q: Ball valve? I require the valve to control both sides of the liquid, one side with liquid flow, and the other side closed!

- I don't know. Solid geometry will happen. God knows me. Suddenly, barriers and French goods

- Q: Three electric ball valve type T and type L what is the difference?

- Electric three way ball valve is a kind of valve, can be divided into L and T type.The T type can cause three orthogonal pipes to connect with each other and cut off third channels, thus diverting and merging the channels.Two pipeline L three ball type valve can only be connected mutually orthogonal, communicating with each other while maintaining the third pipeline, only as a distribution function.Type T and L type reversing diagrams are as follows:Turn left and turn right |

- Q: I've seen a lot of hot water projects. Why do most of them use globe valves, and ball valves are seldom used?.Globe valves have those benefits compared to ball valves (because the cut-off valve is more expensive, I think it is more expensive and more useful. It must have some advantages in that respect.)Is the stop valve more durable than the ball valve?What are the specific differences between the two PPR valves?

- The PPR valve is plug shaped valve, sealing surface flat or cone, fluid along the centerline of the valve for linear motion. Stem movement in the form of lifting rod (stem lifting, hand wheel not lifting), but also lifting, rotating rod type (hand wheel with the valve stem to rotate up and down, nut on the valve body). Valve is only applicable to fully open and fully closed, does not allow for adjustment and throttle.Ball valve has compact structure, reliable sealing, simple structure, easy maintenance, sealing surface and spherical often in the closed state, the media can not easily be eroded, easy operation and maintenance for water, solvents, acids, and natural gas general working media, but also applies to poor working conditions of media, such as oxygen, hydrogen peroxide methane and ethylene, etc., are widely used in various industries. Ball valve body can be integrated, or can be combination.

Send your message to us

DIN Flanged Ball Valve Carbon Steel in good price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 45 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches