DC920 Model Folio Two Color Sheet-fed Offset Press

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of DC920 Model Folio Two Color Sheet-fed Offset Press:

DC920 Two color Sheet-fed Offset Perfector, which is four times productivity of single color Sheet-fed Offset Press, is the main equipment for book printing in the country. The printing process is fully automatic and two colors on both sides of the sheet can be printed simultaneously, thus it is the twice productivity of the common two color sheet fed offset press. This press is suitable for printing books and magazines of two or four colors, especially for printing of multi-varieties and small volume. With its compact structure, the press takes less floor area and can be operated and adjusted conveniently. A sheet transfer cylinder is equipped in the printing unit to tension the sheet so as to prevent the sheet from double printing and scratching to ensure high and accurate printing.

2. Main Features of DC920 Model Folio Two Color Sheet-fed Offset Press:

Adopted swing delivery of paper and constant force spring in the shaft for delivery grippers make less change in the extension length of the spring to ensure smooth and steady operation..

Upper blanket cylinder (with gripper) and lower blanket cylinder make dots appear originally what they are. Precise double paralleled conical roller bearings are adopted in all delivery cylinders make delivery of paper steady and ensure the precision of registrations in printing.

Each printing unit, upper and lower form cylinders are equipped with quick clamping plate, plating with positioned pins, plate tension systems, non-stop axial and circumferential positioning system shown in the meter that shorten the time of plating.

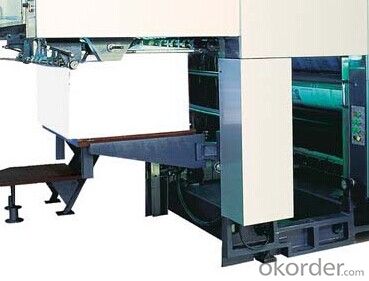

3.DC920 Model Folio Two Color Sheet-fed Offset Press Images:

4.DC920 Model Folio Two Color Sheet-fed Offset Press Specification:

Number Of Colors2

Max.Printing Speed(sph)9,000

Max.Sheet Size(mm2)650×920

Min.Sheet Size(mm2)393×546

Thickness Of Sheet(mm)0.04~0.2Max.

Printing Area(mm2)638×920

Plate Size(mm3)950×810×0.3(0.5)

Upper Blanket Size(mm3)960×850×1.95

Lower Blanket Size(mm3)960×850×1.95

Feeder Pile Height(mm)1300

Delivery Pile Height(mm)910

Total Motor Power(Kw)11Overall

Dimension(mm3)6070×2910×2460

Net weight(approx)(Kg)19,000

5.FAQ of DC920 Model Folio Two Color Sheet-fed Offset Press:

We have organized several common questions for our clients,may help you sincerely:

1)How about your company?

A world class manufacturer & supplier can supply you good products for all worlds customer with high quality and competitive price

2)How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3)How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What is the design basis of automated packaging?! Just for today!

- 1. each manipulator is controlled by a single computer. A packaging machine for the completion of complex packaging operations, the need to be completed by a number of robot hand. When the package is completed, the information is monitored and controlled by the computer controlled camera, and the manipulator completes the required actions according to the instructions of the computer program to ensure the quality of the packaging.2. high resolution of material and thickness. In the packaging process, the thickness and material change in packaging materials is not easy for the human eye to identify changes in the design of packaging machinery is often used by the computer control of the camera and the detector to identify the thickness of packing material and material. The camera has now been developed to automatically check and identify pictures of the camera and display it on the screen. At present, the machine in the processing speed can not be changed, the future should be based on the change of the material through discrimination can change the speed, so as to control the work in the optimal state, complete the packaging process in the shortest time, and realize the automatic cleaning, automatic sterilization and automatic cleaning

- Q: Bread packing machine Product features

- Product features1. double frequency control, bag length is cut, no need to adjust the empty walk, one step in place, save time and save the film.2. man-machine interface, parameter setting is convenient and quick.3. fault diagnosis function, clear failure display.

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is suggested that displacement or velocity should be detected on the transport path of the membrane. Is a more reliable control signal. Of course, you can also detect the angular speed of the recovery drum, such as a code dial and other simple institutions.

- Q: What kind of reducer is commonly used in packaging machinery?

- Generally speaking, gear reducer, planetary gear reducer, and the most common one, these equipment power is relatively small, and some need to take the brakes of the motor reducer

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine packaging production, simple operation and high degree of automation, high efficiency, low packing cost, save labor, reduce the damage and the characteristics of two pollution, by tableware shrink packaging is widely used in all kinds of, is a very mature model

- Q: What is the delay time of the packer's cross sealing?

- You can debug it yourself, set up a parameter, such as a delay of 1 second or a few seconds, look at the action of sealing, you know what time it is.

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- There are PLC control ah, if it is fully automatic, then ask the quality of sealing ah, it is best to let manufacturers give you a live demonstration, the soft power depends on the size of the factory, ah, after-sales service ah!

- Q: What are the packaging machines that use temperature control watches?

- A lot of heating machines have to use thermostat

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Personal advice:In this respect, I suggest you look for the factory in Dongguan, Tangxia, which is the base of vacuum bag production. By logistics or express delivery, the goods will be delivered soon!!

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- This standard specifies the terms and definitions, models, types and basic parameters, technical requirements, test methods, inspection rules and signs, packaging, transportation and storage requirements of the three-dimensional packaging machine for transparent film.

Send your message to us

DC920 Model Folio Two Color Sheet-fed Offset Press

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords