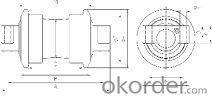

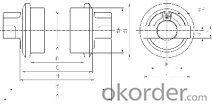

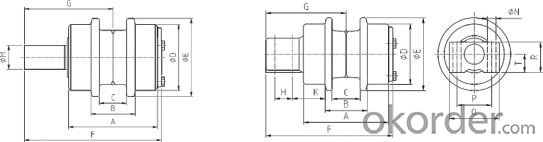

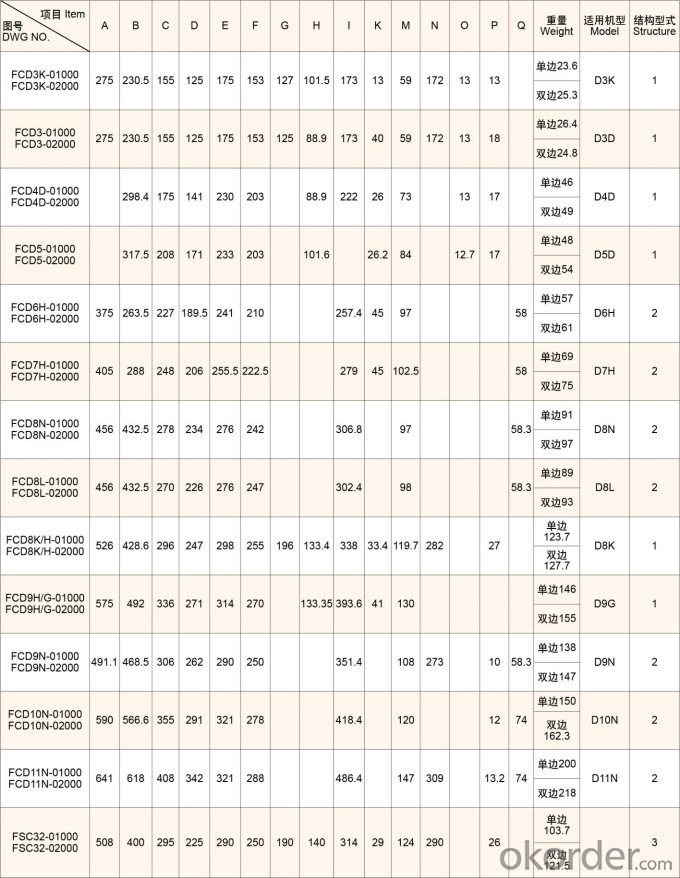

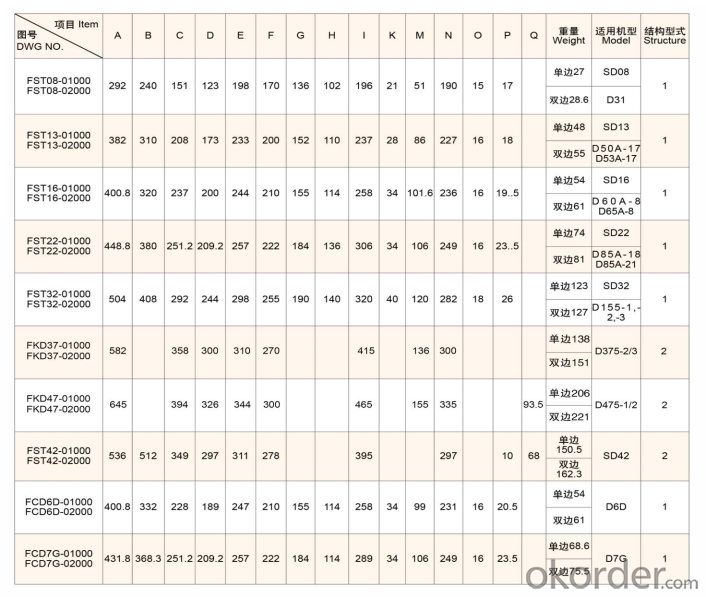

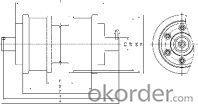

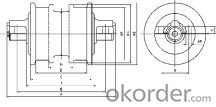

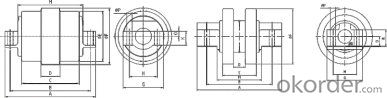

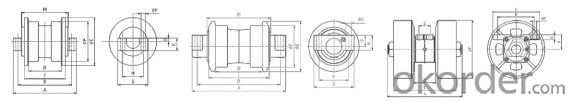

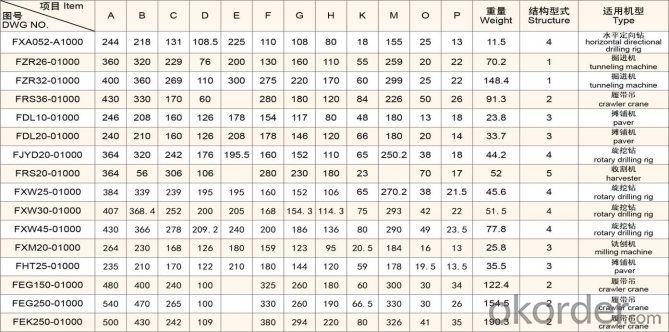

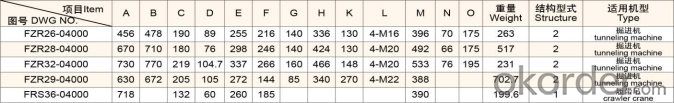

Crawler undrecarriage parts for internattional famous brand

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 88888 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

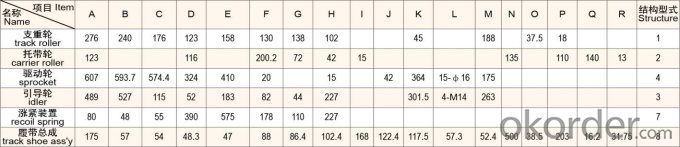

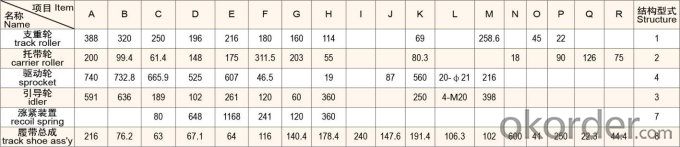

One stop solution for crawler undercarriage (parts) for Cat, Komatsu, Hitachi, Kato, Kobelco, Kubota, Volvo, Doosan, Liebherr, XCMG etc

CNBM heavy equipment specializes in producing crawler undercarriage parts. The total area of our company exceeds 30000 square and our capacity can up to 20000pcs per month. .

We have professional and perfect system from undercarriage parts research and development, quality control and manufacturing, to after-sale service. As well as adopting domestic and foreign advanced technology, seriously implements the IS09001 quality system, strict inspection is carried out for each section. And we always OEM for domestic and foreign manufacturers: XCMG, TZ, LOVOL, Kubota, KATOSCE and so on.

Our company adheres to the principle of quality first, the raw materials use the materials of domestic large steel mills; The processing equipment uses Taiwan famous brand CNC machine tools; In order to ensure the stable output of production process, our company added Multidirectional forging equipment and more than 30 KUKA mechanical arms in 2023. We have a professional physical and chemical laboratory, equipped with perfect inspection equipment: end quenching testing machine, tensile testing machine, impact testing machine, Metallographic microscope, spectrum Analyzer, three-coordinate measuring machine and all kinds of hardness testers, ----- adhere to "customers as the center, strive for the market by quality, seek development by innovation, make progress by improvement." ensures the product quality from raw materials to finished products, making the product quality always in the leading position in the industry.

With more than 10 years export experience, large quantities of products are exported to more than 30 countries and regions of Italy, Russia, Japan, Australia, Saudi Arabia, theUnited States, Canada, Brazil, Switzerland, United Arab Emirates.

- Q: What are the sectors of machine building and parts processing?

- Industry to classify, it is not very strict. For example, the insurance industry, mining, energy, food, hotels, real estate services industry, garment industry, advertising industry, aerospace, aviation, chemical, chemical, construction, health care, education, training, computer, metal smelting, fire, police, soldiers, accounting, beauty, body, media, publishing, wood, paper retail, wholesale, agriculture, tourism, justice, lawyers, sports, sports, arts, entertainment, medical, art, design, banking, finance, Internet, music, dance, postal, courier, transport, consulting services.

- Q: What are the main functions of construction equipment monitoring system?

- To date, the console has always been built into blocks, in terms of control functions and number of cameras. Can be assembled according to requirements. In addition, the character generator is also arranged in the total time and address on the console, the date and time, minutes and seconds are displayed by this device, and be put in place to monitor the address and name display. It can be recorded on the video recorder, so that it will be convenient for future reference.

- Q: What is equipment manufacturing and machinery manufacturing? What's the difference between them?

- Major technical equipment refers to the technical difficulty in equipment manufacturing, complete and strong, is of great significance, has a significant impact on the national economy need to be beneficial to the people's livelihood, complete sets of major technical equipment organizations across sectors, industries and regions to complete.

- Q: What are the principles, performances and uses of the commonly used construction machinery equipment?

- 2.: Principle: loader loader work, powered by a flywheel of the diesel engine to the hydraulic torque converter, the torque converter will drive to the gearbox, and before and after the output flange of the gearbox, the power output of the gearbox after the transmission shaft are respectively transmitted to the front and back drive axle to drive the wheels forward. Performance: 1) Central articulated frame, turning radius is small, flexible and convenient operation in narrow space; 2) using hydraulic mechanical transmission, according to the size of the external resistance and automatic stepless speed change, which can make full use of engine power, and improve the maneuverability, simplifies the loader operation. Is to protect the transmission parts and engine; 3) adopts full hydraulic steering, power shift transmission, hydraulic or flexible manipulation, portable and flexible machine; 4) stable and reliable operation; wide use of low-pressure off-road tires, rear axle swing, with good cross-country performance and through the performance by 5); gas cap oil disc brake system and brake foot up, emergency braking system, the braking performance is safe and reliable; 6) with advanced structure and bright cab. The air conditioning system operates more comfortably. Uses: loaders are mainly used for shovel, loading, unloading, transport of soil and stone a kind of bulk materials, rock and hard soil can also be slightly shovel operations.

- Q: How are the machine parts stacked?

- Then there is a point to note, that is, from there to get used, must be put back where, so that will be organized, all things are owned by you, it will not mess.

- Q: Construction machinery production need to deal with what documents?

- At all levels of production safety responsibility system, mainly refers to: the legal representative of the safe production responsibility system; the responsible person in charge of safety production safety responsibility system; the technical director (Chief Engineer) production safety responsibility system; the safety department (Department) Changan production responsibility system; responsibility for production safety, the project manager; specifically (and) post safety responsibility system for production safety; construction technician (technician), safety production responsibility system; 8 class (Group) Changan production responsibility system; workers, production safety responsibility system. Departments responsible for production safety system, mainly in accordance with the functions of enterprises set up departments, the corresponding formulation of the responsibility system for safety in production.

- Q: How are buildings, installations and materials divided?

- Equipment generally includes the following: (1) all kinds of equipment and the equipment with the arrival of accessories, spare parts and equipment attached to the body made of ladders, platforms, railings and pipes. (2) various gauges, instruments and automatic control devices, experimental instruments, instruments and meters in the main part of the equipment. (3) components of equipment, such as oils, chemicals, etc. attached to the equipment body.

- Q: Where does Heilongjiang do the most construction machinery?

- Construction machinery is an important component of equipment industry. To sum up, all mechanical equipment necessary for comprehensive mechanical construction projects, such as earthwork construction, pavement construction and maintenance, mobile lifting, loading and unloading operation, and various construction projects, are called construction machinery

- Q: Mechanical bearings, all types? Roughly

- The separable bearing is composed of a raceway and a needle roller and cage assembly that can be arbitrarily assembled with a punched thin raceway (W) or a machined thick raceway (WS). A non separable bearing is an integral bearing consisting of a precision machined raceway and a needle and cage assembly. This type of bearing can bear one-way axial load. With small space, it is beneficial to the compact design of machinery. Most of them only use needle roller and cage assembly, and the installation surface of shaft and shell is used as raceway surface.

- Q: What functions should be achieved in mechanical structure design?

- Mechanical structure design plays an important role in mechanical design. This chapter mainly discusses the characteristics, steps and mode of thinking of mechanical structure design. The working principle and design requirements of the machine assembly is a major factor in determining the structure and shape of the parts, followed by the selection of materials, manufacturing process requirements, which has the advantages of good manufacturability (processing and assembly). In addition, the perfection of the structure and shape of the parts has a great influence on the strength and stiffness.

Send your message to us

Crawler undrecarriage parts for internattional famous brand

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 88888 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords