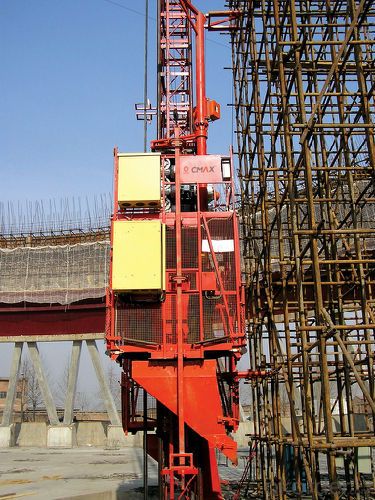

Construction Hoist Single Cage SCD200 for sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Construction Hoist Description

The building hoist can be widely used in industrial and civilian construction, bridge, under well, big chimney as well as shipping industry to carry people and materials. As permanent or semi-permanent equipment, elevator can be used in different sites such as warehouse, high tower, etc.

With the advantages of reliable performance, safety, easy carrying, high adaptability, it can reduce operators’ work intensity.

With many advanced technology integrity, strict control on each making process, high ratio of price and quality, Bona building hoist has become a symbol of lifter with high quality and excellent after-sales service.

Packaging & Delivery of Construction Hoist

Packaging Detail: Nude package Delivery Detail: 25-30days

Main Parts of Construction Hoist

● The gearing adopts imported bearing, enameled cable, and oil seal.

● The electric parts adopt products from world renowned manufactures such as Schneider, Siemens, and LG.

● The racks and pinion adopts special material and heat-treatment technique, which prolong the life of these parts.

● The steel structure uses quality steel from famous domestic manufactures.

● The surface of the structure can apply paint-spray, parkerozing baking finish or hot galvanizing processing according

to users requirements,

● The cage can be produced and decorated by aluminum molded board, punched-plate or figured aluminm board.

Construction Hoist Specifiction

Single cage High speed

Model | Speed(m/min) | Deadweight(kg) | Motor(KW) | Counterweight | Specification(L×W×H)(m) |

SC100G | 96 | 1000 | 3×22 | No | 2.5×1.3×2.5 |

SC120G | 96 | 1200 | 3×22 | NO | 3.0×1.3×2.5 |

SCD200G | 96 | 2000 | 3×15 | Have | 3.2×1.5×2.5 |

SC200G | 96 | 2250 | 3×22 | No | 3.2×1.5×2.5 |

SC270GS | 96 | 2700 | 3×22 | No | 3.8×1.5×2.5 |

SCD270G | 96 | 2700 | 3×18.5 | Have | 3.8×1.5×2.5 |

SCD300G | 96 | 3000 | 3×22 | Have | 4.0×1.5×2.5 |

SCD320GS | 96 | 3200 | 3×22 | Have | 4.2×1.5×2.5 |

Single cage Medium speed

SC100GZ | 63 | 1000 | 3×15 | No | 2.5×1.3×2.5 |

SC120GZ | 63 | 1200 | 3×15 | No | 3.0×1.3×2.5 |

SCD200GZ | 63 | 2000 | 2×15 | Have | 3.0×1.3×2.5 |

SC200GZ | 63 | 2000 | 3×18.5 | No | 3.0×1.3×2.5 |

SC225GZ | 63 | 2250 | 2×18.5 | No | 3.2×1.5×2.5 |

SC225GZ | 63 | 2250 | 3×18.5 | Have | 3.6×1.5×2.5 |

SCD250GZ | 63 | 2500 | 2×18.5 | Have | 3.6×1.5×2.5 |

SC250GZ | 63 | 2500 | 3×18.5 | Have | 3.8×1.5×2.5 |

SCD270GZ | 63 | 2700 | 2×18.5 | Have | 3.8×1.5×2.5 |

SC270GZ | 63 | 2700 | 3×22 | NO | 4.0×1.5×2.5 |

SCD300GZ | 63 | 3000 | 3×15 | Have | 4.0×1.5×2.5 |

SCD320GZ | 63 | 3200 | 3×15 | Have | 4.2×1.5×2.5 |

Single cage standard speed

SC100TD | 36 | 1000 | 2×11 | NO | 2.5×1.3×2.5 |

SC120TD | 36 | 1200 | 2×11 | NO | 3.0×1.3×2.5 |

SC200TD | 36 | 2000 | 3×11 | NO | 3.0×1.3×2.5 |

SCD200TD | 36 | 2000 | 2×11 | Have | 3.2×1.5×2.5 |

SC270TD | 36 | 2700 | 3×15 | NO | 3.6×1.5×2.5 |

SCD270TD | 36 | 2700 | 2×11 | Have | 3.8×1.5×2.5 |

SC320TD | 36 | 3200 | 3×18.5 | NO | 4.0×1.5×2.5 |

SCD320TD | 36 | 3200 | 2×11 | Have | 4.2×1.5×2.5 |

FAQ of Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: Describe the routine maintenance and inspection procedures for a building hoist.

- <p>The maintenance and inspection process for a building hoist involves several key steps to ensure safety and functionality. Regular visual inspections should be conducted to check for any visible damage or wear. Monthly inspections should include testing the emergency stop and limit switches, as well as lubricating moving parts. Quarterly inspections may involve checking the electrical connections and verifying the correct operation of safety devices. Annual inspections typically require a thorough examination by a qualified person, including testing the load-bearing capacity and ensuring all safety features are in good working order. Additionally, records of all inspections and maintenance should be kept for reference and compliance with safety regulations.</p>

- Q: This question asks whether a building hoist can be utilized in both indoor and outdoor environments for lifting objects.

- <p>Yes, a building hoist can be used both indoors and outdoors for lifting objects. These hoists are designed to handle heavy materials and are often used in construction settings. However, their use is subject to specific conditions and safety requirements. Outdoor use may require additional considerations such as weatherproofing and stability in various weather conditions, while indoor use must adhere to space limitations and structural integrity of the building. Always ensure that the hoist is suitable for the environment and that all safety protocols are followed to prevent accidents.</p>

- Q: Can a building hoist be utilized for the transportation of objects within and between buildings?

- <p>Yes, building hoists are specifically designed to move objects vertically within buildings. They are commonly used in construction to lift materials and equipment to different floors. Additionally, they can be employed to transport objects into and out of buildings, especially when access is limited or when heavy loads need to be moved over short vertical distances. However, it's important to adhere to safety guidelines and regulations when operating a building hoist to ensure the secure and efficient movement of objects.</p>

- Q: This question asks for the method to determine the maximum load that a single-rope lift can handle.

- <p>To calculate the load capacity of a single-rope lift, you need to consider several factors including the strength of the rope, the diameter of the rope, the angle of the lift, and the safety factor. The basic formula involves determining the maximum load the rope can bear based on its material properties and construction, which is then adjusted by the safety factor to account for dynamic loads and potential wear. The formula might look something like this: Load Capacity = (Tensile Strength of Rope 脳 Area of Rope Cross-Section 脳 Safety Factor) / (Cosine of Angle of Incline). It's important to consult with engineering standards and the lift manufacturer's specifications for precise calculations.</p>

- Q: Is it possible for a building hoist to simultaneously lift and lower various materials?

- <p>Yes, a building hoist can be used to raise and lower different materials at the same time, provided it has the necessary capacity and the materials are properly secured. This is often done by using multiple hooks or platforms, each designated for different materials. It's crucial to ensure that the combined weight does not exceed the hoist's load limit and that safety protocols are strictly followed to prevent accidents.</p>

- Q: Is it possible to use personal components to fix a malfunctioning building hoist?

- <p>While it might be tempting to use your own parts to repair a malfunctioning building hoist, it is generally not recommended. Building hoists are complex pieces of machinery that require specific components to function safely and efficiently. Using non-standard parts can lead to further damage, safety hazards, and may void any warranty on the hoist. It's crucial to use parts that meet the manufacturer's specifications to ensure the hoist operates correctly and safely. Always consult with a professional or the manufacturer for repair advice and parts.</p>

- Q: This question asks for the criteria or factors to consider when selecting a building hoist for a particular construction task.

- <p>Choosing a suitable building hoist involves considering several factors: the weight capacity required for the materials you need to lift, the height of the building or structure, the frequency of use, and the available space for installation. Ensure the hoist complies with safety standards and regulations. Consider the hoist's speed and efficiency, as well as the ease of maintenance and operation. Consult with hoist manufacturers or experts to assess your specific needs and select the most appropriate model for your construction project.</p>

- Q: The question asks about the typical duration a building hoist can function before needing replacement or significant repair.

- <p>The lifespan of a building hoist can vary significantly based on factors such as usage frequency, maintenance, and the quality of the hoist itself. Generally, with proper care and regular maintenance, a building hoist can last anywhere from 10 to 20 years. However, heavy usage and inadequate maintenance can shorten this lifespan, while some high-quality hoists may exceed the average lifespan with fewer issues.</p>

- Q: This question asks if building hoists can be utilized both indoors and outdoors, and if they can operate under windy or rainy weather conditions.

- <p>Building hoists can be used both indoors and outdoors, but their operation in windy or rainy conditions depends on specific safety guidelines and the hoist's design. Outdoor hoists must be designed to withstand weather conditions and should be equipped with weatherproof covers to protect against rain and wind. In windy conditions, hoists may have operational limits based on wind speed to ensure safety. It's crucial to follow the manufacturer's guidelines and local regulations regarding weather conditions to prevent accidents and ensure the hoist's safe operation.</p>

- Q: Construction site construction elevator and tower crane, which unit security check and acceptance?

- Different but most likely is the construction elevator

Send your message to us

Construction Hoist Single Cage SCD200 for sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords