Construction Hoist Single Cage Coated Galvanize

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Building Hoist Description

Condition: New

Application: Construction

Payload(kg):2500

Lifting Speed(m/min):0~60

Motor Power(kw): 3*18.5

Safety Device: SAJ50-1.4

Cage: Single

Counterweight: No

Certification: CE,ISO

Place of Origin: China(Mainland)

Model Number: Type:SC250

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package

Delivery Detail: 25-30days

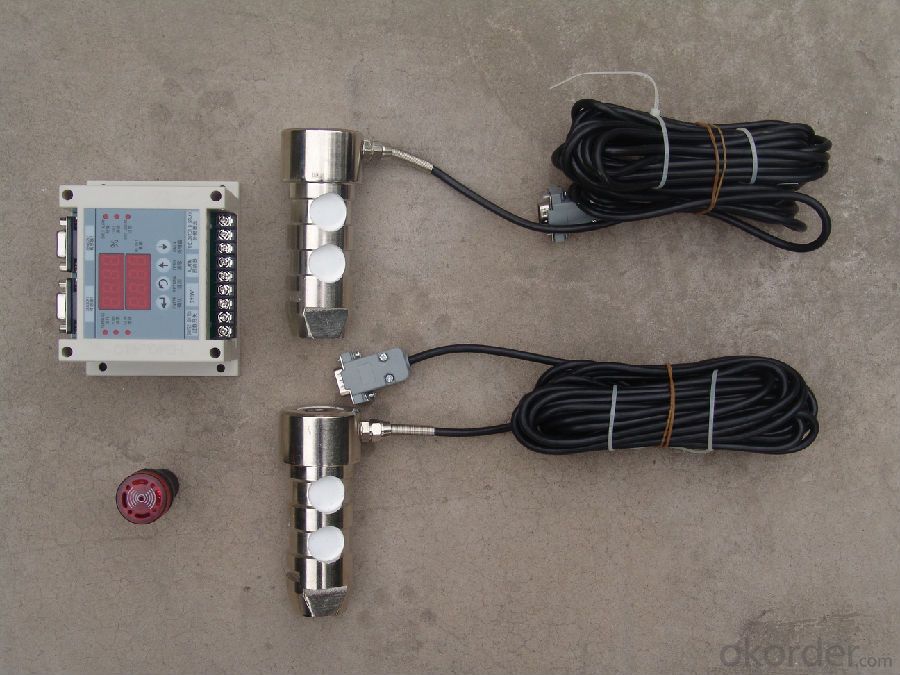

Building Hoist Images

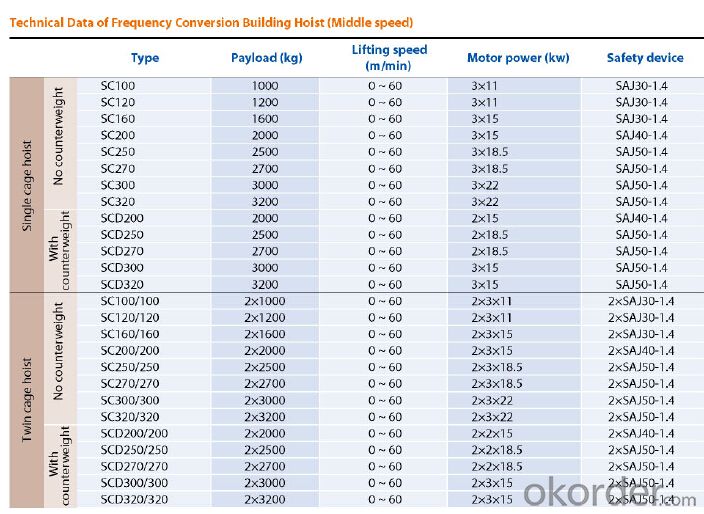

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: What about the energy efficiency of the escalator

- Variable frequency construction elevator energy saving effect general. Frequency conversion is not energy efficient. The difference between the frequency and the common machine is the smoothness and speed of the operation. Frequency conversion speeds up to 90m / 1 minutes and the average is only 35m / 1 min Frequency conversion when parking is slow down and stop Ordinary is directly stop delay parking and adjustment made door light who bow Angle decyl with brush spring connection will be better. The frequency conversion requires the site voltage to be strictly a little bit looser than the voltage requirement Energy consumption is: according to the elevator drive mechanism for general three transmission two kinds of the elevator are three 11 kw motor, that their energy consumption are 3 x 11 = 33 kw is hours each hanging basket consumes electricity 33 degrees, the actual power consumption will be bigger.

- Q: Is it possible to utilize building hoists in environments with high altitudes?

- <p>Yes, building hoists can be used in high-altitude environments, but their performance may be affected. At high altitudes, reduced air density can lead to decreased efficiency in hoist operations, particularly those powered by combustion engines. It's crucial to select hoists designed for high-altitude use, which may include features such as high-altitude ignition systems and special lubricants. Additionally, regular maintenance and adjustments to the hoist's operation parameters are necessary to ensure safety and optimal performance.</p>

- Q: This question asks for a comparison between electric and hydraulic building hoists, highlighting their main differences.

- <p>Electric building hoists are powered by electricity and use electric motors to lift and lower loads. They are generally quieter, require less maintenance, and can be more energy-efficient. Hydraulic building hoists, on the other hand, use hydraulic pressure to move loads. They tend to be more powerful and can lift heavier loads, but they may require more maintenance and are not as energy-efficient. Electric hoists are often preferred for lighter loads and indoor use, while hydraulic hoists are chosen for heavy-duty applications and outdoor use where power is not readily available.</p>

- Q: Why do you ask the construction elevator to be a certain distance from the structure? Is very close to if not you can not bother to do delivery channel security protection or something, out of the elevator out directly, and attachment should be able to get more easily, to solve. Thank you very much!!

- The country stipulates that the distance between the moving parts of the elevator and the building and the fixed construction equipment should not be less than 0.25 meters. It's mainly about safety.

- Q: The question asks about the typical duration a building hoist can function before needing replacement or significant repair.

- <p>The lifespan of a building hoist can vary significantly based on factors such as usage frequency, maintenance, and the quality of the hoist itself. Generally, with proper care and regular maintenance, a building hoist can last anywhere from 10 to 20 years. However, heavy usage and inadequate maintenance can shorten this lifespan, while some high-quality hoists may exceed the average lifespan with fewer issues.</p>

- Q: Can a building hoist be utilized for lifting objects that exceed manual lifting capabilities?

- <p>Yes, building hoists are specifically designed to lift and transport objects that are too large or heavy for manual lifting. They are commonly used in construction to move materials and equipment to various levels of a building. Building hoists are equipped with safety features and can handle substantial weight, making them an essential tool in construction projects where heavy objects need to be moved efficiently and safely.</p>

- Q: This question asks for a comparison of vertical and horizontal lifting in the context of building hoists, highlighting their distinct characteristics.

- <p>Vertical lifting in a building hoist refers to the movement of materials directly up or down, which is essential for transporting goods between different floors or levels of a building under construction. Horizontal lifting, on the other hand, involves moving materials across a horizontal plane, which is useful for moving items along a floor or between different parts of a construction site. Vertical lifting is typically more common in hoists due to the nature of building construction, requiring frequent vertical transport. Horizontal lifting is less common but can be implemented with specialized equipment or by combining vertical and horizontal movements. The choice between vertical and horizontal lifting depends on the specific requirements of the construction project and the layout of the site.</p>

- Q: What is the need for the sc200/200 construction elevator cable?

- The company now USES 3X25 + 2x10 cables

- Q: For example, what records do you want to have a third party monitoring?

- Important parts replacement needs to be changed to the qualification, the procedure is like the new ladder, according to the new ladder standard test.

- Q: Whether the construction elevator is a dual-purpose elevator

- The vertical transportation machinery in construction is mainly the material elevator and construction elevator. Material hoist can slide can't manned, suitable for multilayer use, construction elevator is used only for the top, both manned and can slide, in general the construction elevator for dual-use goods of choose and employ persons outside the elevator.

Send your message to us

Construction Hoist Single Cage Coated Galvanize

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords