Construction Hoist New SC320 for Building

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of SC320 Construction Hoist Description

To serve the increasing demand for highrise construction, we developed the high speed VF hoist, with a max.lifting speed of 96 m/min.

It has the following structure:

1. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

2. Adopts open loop V/F control: the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoids slipping during downward stopping of hoist.

3. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the energy consumption and mitigates effects to on site electric equipments.

4. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack,pinion and the brake and prolongs the spare parts'life.

5. The VF system also has the over voltage protection, low voltage protection, overcurrent, overload and anti-stalling protection functions.

6. The System applies the special software for hoists developed by our company, making the operation more safe and reliable.

Main Features of SC320 Construction Hoist

1. The recomended cage dimension(L*W*H)(m): 2.0*1.0*2.5, 2.5*1.0*2.5, 2.5*1.3*2.5, 3.0*1.5*2,5, 3.2*1.5*2.5, 3.8*1.5*2.5, 4.0*1.5*2.5, 4.2*1.5*2.5 etc. We can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to yout requirements.

3. The mast section and the tie-in surface can adopt paint-spray, or hot galvanizing processing.

4. Both domestic and imported driving systems are available.

SC320 Construction Hoist Specifiction

SC series product also has special design, such as reinforced guide rail with cross-section of 800mm, inclined type, special for cooling tower, etc. All the double cage building hoist can be changed into single cage type,

| Type | Payload(kg) | Lifting Speed (m/min) | Motor Power(kw) | Safety Device | ||

| Single Cage Hoist | No Counterweight | SC100 | 1000 | 0~60 | 3*11 | SAJ30-1.4 |

| SC120 | 1200 | 0~60 | 3*11 | SAJ30-1.4 | ||

| SC160 | 1600 | 0~60 | 3*15 | SAJ30-1.4 | ||

| SC200 | 2000 | 0~60 | 3*15 | SAJ40-1.4 | ||

| SC250 | 2500 | 0~60 | 3*18.5 | SAJ50-1.4 | ||

| SC270 | 2700 | 0~60 | 3*18.5 | SAJ50-1.4 | ||

| SC300 | 3000 | 0~60 | 3*22 | SAJ50-1.4 | ||

| SC320 | 3200 | 0~60 | 3*22 | SAJ50-1.4 | ||

| With Counterweight | SCD200 | 2000 | 0~60 | 2*15 | SAJ40-1.4 | |

| SCD250 | 2500 | 0~60 | 2*18.5 | SAJ50-1.4 | ||

| SCD270 | 2700 | 0~60 | 2*18.5 | SAJ50-1.4 | ||

| SCD300 | 3000 | 0~60 | 3*15 | SAJ50-1.4 | ||

| SCD320 | 3200 | 0~60 | 3*15 | SAJ50-1.2 |

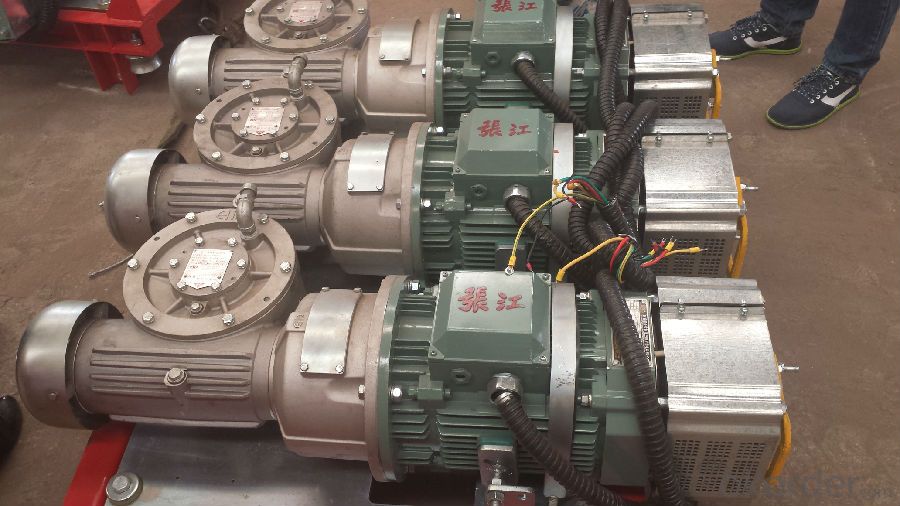

Images of SC320 Construction Hoist

FAQ of SC320 Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: This question asks if a building hoist can be utilized in both commercial and residential settings.

- <p>Yes, a building hoist can be used for both commercial and residential purposes. These hoists are designed to lift materials and workers to various levels of a building under construction. In commercial settings, they are often used in high-rise buildings, while in residential construction, they are used for multi-story homes or apartment complexes. However, the specific type and capacity of the hoist should be chosen based on the project's requirements and safety regulations must be strictly adhered to in both types of construction.</p>

- Q: Explain the differences between electric and electric-motor-driven building hoists in a few sentences.

- <p>Electric hoists are powered directly by electricity and use electric motors to lift and lower loads. They are typically smaller and more portable, suitable for lighter loads and indoor use. Electric-motor-driven hoists, on the other hand, use an electric motor to power a separate mechanism, often a winch or pulley system, to move loads. These are generally more robust, capable of handling heavier loads, and are often used in construction and industrial settings. The main differences lie in their power transmission methods, load capacity, and the environments in which they are used.</p>

- Q: How does the driver of the construction elevator do the search for a sudden power failure

- When the elevator is running in an abnormal condition, it should stop immediately and take effective measures to bring the ladders down to the ground floor. When the electric is out of control in operation, the stop button should be pressed immediately. The stop button is not allowed until the failure is ruled out.

- Q: Is it possible to use personal components to fix a malfunctioning building hoist?

- <p>While it might be tempting to use your own parts to repair a malfunctioning building hoist, it is generally not recommended. Building hoists are complex pieces of machinery that require specific components to function safely and efficiently. Using non-standard parts can lead to further damage, safety hazards, and may void any warranty on the hoist. It's crucial to use parts that meet the manufacturer's specifications to ensure the hoist operates correctly and safely. Always consult with a professional or the manufacturer for repair advice and parts.</p>

- Q: This question asks about the typical issues encountered when constructing a building hoist and the methods to address these problems.

- <p>Common problems in building hoists include mechanical failure, safety hazards, and improper installation. Solutions involve regular maintenance to prevent mechanical issues, strict adherence to safety protocols to mitigate hazards, and professional installation to ensure the hoist is correctly set up. Additionally, using modern technology for monitoring and control can help to identify and rectify problems early. Ensuring proper training for operators is also crucial for the safe and efficient operation of building hoists.</p>

- Q: This question asks whether a building hoist can be utilized in construction or demolition activities.

- <p>Yes, a building hoist can be used for both construction and demolition work. In construction, hoists are essential for transporting materials and personnel vertically within a building under construction. They are designed to handle heavy loads and operate safely at significant heights. In demolition, hoists can be used to remove debris and transport workers to different levels of a structure being dismantled. However, it's crucial to ensure that the hoist is suitable for the specific task and that all safety protocols are followed to prevent accidents.</p>

- Q: What precautions should be taken when using manual lifting equipment to ensure safety?

- <p>Safety measures for using manual lifting devices include inspecting equipment for damage before use, ensuring the load is within the device's weight capacity, using proper lifting techniques, maintaining a clear path for lifting, and securing the load to prevent shifting. Always wear appropriate personal protective equipment, such as gloves and safety shoes. Never exceed the rated capacity of the lifting device, and avoid sudden or jerky movements that could cause loss of control. Regular maintenance and training on safe lifting practices are also crucial to prevent accidents.</p>

- Q: How many meters is the wall of the construction elevator?

- The height is greater than 60 meters every six meters.

- Q: This question asks if a building hoist can be utilized in both commercial and residential settings.

- <p>Yes, a building hoist can be used for both commercial and residential purposes. These hoists are designed to lift materials and workers to various levels of construction sites. In commercial settings, they are often used in the construction of office buildings, shopping centers, and other large-scale projects. In residential construction, they are used for multi-story apartment buildings or private homes. It's important to note that the specific type and capacity of the hoist should be suitable for the scale and requirements of the project to ensure safety and efficiency.</p>

- Q: Is it possible for a hydraulic cylinder in a building hoist to experience leakage or failure?

- <p>Yes, a hydraulic cylinder in a building hoist can leak or break. Leaks can occur due to worn seals, damaged hoses, or corroded cylinder walls. Breakage may result from excessive pressure, manufacturing defects, or metal fatigue. Regular maintenance and inspection are crucial to detect and prevent such issues, ensuring the safety and efficiency of the hoist system.</p>

Send your message to us

Construction Hoist New SC320 for Building

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords