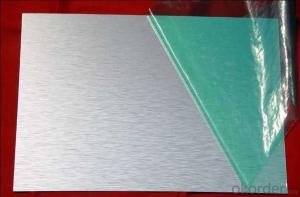

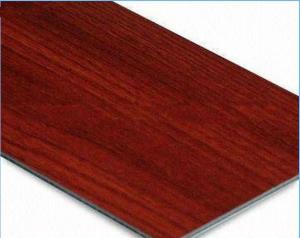

Composite panel / good decoration effec

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Model Number:FD-ACP-10

MOQ:300 Sheets

FOB Price: US$ 3 - US$ 18

FOB Port:China (Mainland)

Lead Time: 5 - 15 days

Payment Terms:Letter of Credit (LC, L/C)

Country of Origin:China (mainland)

Specifications:

Thicknesses: 1~8mm

Widths: 1,000~2,000mm

Guarantee: 10 years (PPG paint)

Core: Unbreakable and fireproof A2

CE, ISO, green leaf approvals

Materials:

Front: aluminum alloy sheet coated with pleochromatic PVDF paint on surface

Core: nontoxic low density polyethylene

Back: aluminum alloy sheet coated with polyester resin painting

- Q: OKorder Xingyi where to sell auspicious aluminum-plastic plate? Used in the bathroom decoration, recommended

- You can buy in Kunming manufacturers, the price cheaper than the other side of OKorder, a home called clouds like building materials

- Q: What are the materials for making aluminum-plastic panels?

- Aluminum-plastic composite panels are made of multi-layer composite material, the upper and lower layers of high-purity aluminum alloy plate, the middle of non-toxic low-density polyethylene (PE) core board, the front also paste a protective film. For outdoor, aluminum-plastic panels coated with fluorocarbon resin (PVDF) coating, for the interior, the front use of non-fluorocarbon resin coating.

- Q: About the introduction

- Aluminum-plastic composite panel referred to as aluminum-plastic plate, is made by the surface treatment and coated with aluminum paint as the surface, polyethylene plastic plate as the core layer, after a series of process processing complex made of new materials. The aluminum-plastic panels were first developed by the German company Aiusingen and later improved by Forken and Aloca. 90 years later, the product quality gradually stable, reached a high level. As the aluminum-plastic plate is composed of two different materials (metal and non-metallic), it retains the original composition of materials (metal aluminum, non-metallic polyethylene plastic) the main features, but also to overcome the lack of raw materials , And then get a lot of excellent material properties. Such as luxurious and beautiful, colorful decorative; weathering, corrosion resistance, impact resistance, fire, moisture, heat insulation, sound insulation, light resistance; light, easy processing, easy handling, quick construction and other characteristics. These properties for the aluminum-plastic plate opened up a broad application prospects. Aluminum-plastic panels Due to the many advantages of material properties, it is widely used in a variety of architectural decoration, such as ceilings, pillars, counters, furniture, telephone booths, elevators, stores, billboards, And so on, has become the representative of the three curtain walls (natural stone, glass curtain wall, metal curtain wall) metal curtain wall, in developed countries, aluminum-plastic panels are also used in the bus, the manufacture of train boxes, aircraft, Equipment, equipment, such as the outer box.

- Q: How is Allegro embossed aluminum-plastic plate is an aluminum-plastic plate, who can describe in detail?

- Athena embossed aluminum-plastic plate is the use of coated aluminum plate by a special fine process to suppress a variety of convex and convex pattern of aluminum.

- Q: Please provide more than two brands, Xianxie the.

- 200 yuan ah Find me cheap ah

- Q: What are the factors that affect the price of aluminum-plastic panels? Big gods help out

- The price of aluminum-plastic plate is determined by a number of factors, mainly by the aluminum series, aluminum-plastic plate specifications, aluminum-plastic surface coating, aluminum-plastic plate thickness, aluminum-plastic plate thick aluminum, core material and other factors Impact. For example, from the surface of aluminum-plastic plate coating classification, can be divided into polyester aluminum-plastic plate and fluorocarbon aluminum-plastic plate. Fluorocarbon aluminum plate because of its good weather resistance (fluorocarbon, also known as PVDF), can keep 15 years does not fade, used for outdoor decoration; polyester aluminum plate (polyester, also known as PE) is used for indoor. As the fluorocarbon aluminum plate of the weather resistance is better, the price is higher than the polyester aluminum plate. Of course, the greater the thickness of aluminum-plastic or aluminum, the higher the price, the other is no different.

- Q: Now sell a lot of aluminum-plastic plate, are OKorder auspicious aluminum-plastic plate, which is good?

- Yes ah, cloud like building materials is authentic

- Q: What is the plastic core material of aluminum-plastic plate, where there is to sell?

- Aluminum-plastic plate core material is granular, the use of high-temperature melting plastic particles pressed from, if you need not much, you can and open the aluminum plate factory friends take some.

- Q: Aluminum plate fire rating how to determine

- The determination of the fire level can be detailed GB8624-2006, there are grading indicators and instructions.

- Q: Aluminum-plastic plate universal flat-panel printer which is good, how much money?

- Aluminum-plastic plate universal printer is a kind of digital inkjet printer can print a lot of manufacturers concentrated in the coast, there are: Jintian, Han extension, and so on, manufacturers are more than one said, probably the price of tens of thousands to Twenty tens of thousands ranging from a penny goods, from the nozzle, configuration, after-sales service comparison.

Send your message to us

Composite panel / good decoration effec

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords