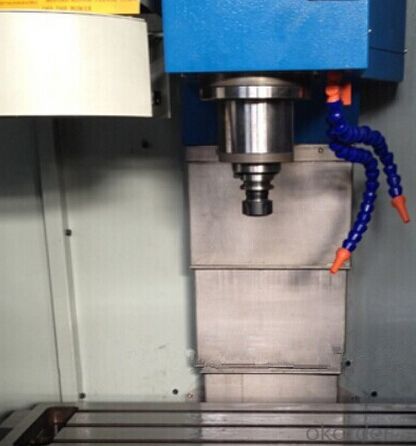

Multi-purpose Small Mini CNC Milling Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.the structure use the high toughness,high iron manufacturing2.three axis are installed linear guide rail

3.CE certificated

A. Features

1.Main structure of lathe bed and column adopt reasonable

Fabric reinforcement to enhance against earthquakes.

2. Can not be out of shape and chip removal is fluent..

3. Three axis are installed linear guide rail,to maintain high precision

under highspeed operation for a long time.Fast moving shortens the

positioning time and increase productivity.

4.The structure of a precision pressure equipment is connected with the

automatic lubrication device,use the special bearings which are used for ball

screw,ensure that the positioning accuracy and the contour control accuracy

and mobile shaft rigidity.

5.Three axis are servo feed axis,spindle servo spindle with rigid tapping function,

to improve the machining accuracy,to reduce processing time and improve productivity.

6.You can choose the CNC controler system for the machine

B. Product Overview

1,The overall structure use the high toughness, high iron manufacturing,and after a

highly efficient annealing heat treatment,it effectively eliminate material internal stress,

to ensure the precision of the best stability and durability.

2,Stand column design is big span, it has high rigidity and high stability. It connected to

a strong, stable large casting lathe bed,to ensure the accuracy of the machined part and precision.

3,Counterweight system behind the stand column, and it has biaxial oriented, so the spindle

box cutting move more smoothly,effectively restrain the negative effects of vibration,to ensure

the requirement of accuracy.

4,Three axis use the P3 precision ball screw,cooperate with double nuts washers preloaded,

eliminate back lash in advance,to achieve high stability of positioning accuracy and repeat precision.

5,Three axis machine tool are installed high precision linear rolling guide,to ensure the high

precision of processing, meanwhile increased the speed of fast forward.

6,Three axis feed driven use servo motor and screw straight league,transmitting stable, and

no back lash.And it has good rigidity and damping performance,greatly improved the dynamic

rigidity of transmission system

7,Precision highspeed spindle unit and AC servo motor connected through the synchronous belt ,

low noise, little vibration, low calorific value.Available for milling, drilling, reaming, boring, ream,

tapping and other processing.

8.Column Z axis has large travel (up to 500 mm), so that the processing of high workpiece no

need to be on large machine tools, and at the same time leaving enough space for adding 4th

axis etc.

9.Sheet metal integration design, comprehensive protection, good integrity, high impermeability.

Open sliding door design, more convenient for loading and unloading workpieces.

C.Specification

Model | M400 |

Table size (mm) | 760×210 |

T-Slot | 14×3×63 |

Max load (kg) | 200 |

Travel of X axis (mm) | 400 |

Travel of Y axis (mm) | 230 |

Travel of Z axis (mm) | 500 |

Distance from spindle nose to table (mm) | 110-610 |

Distance from spindle center to column (mm) | 320 |

Spindle Taper | ISO30 |

Spindle speed(rpm) | 6000/8000/10000 |

Mpa | 0.6 |

Spindle servo motor power(kw) | 2.2 |

Spindle motor torque (Nm) | 27 |

X/Y/Z axis servo motor torque (mm) | 4 |

X/Y/Z axis Max feeding speed (mm/min) | 5000 |

X/Y/Z axis Max fast moving speed (mm/min) | 12000 |

Coolant pump power (w) | 120 |

Rated flow (L/min) | 25 |

CNC Controller | SIEMENS 808D |

Positioning accuracy (mm) | ±0.012 |

Repeating accuracy (mm) | ±0.006 |

Net weight/ Gross weight(kg) | 1150/1250 |

Packing size (mm) | 1460×1940×2180mm |

D.Standard configuration

Security locks, lubricating system, cooling tank and dust pans, operation indicator light (red,

yellow, green), working lamp, air gun, toolbox 1 set , instructions 1 set , a set of eight knife.

Optional configuration

Vertical milling cutter bar BT30, quickchange drill collet BT30, spring collet milling cutter

bar BT30, Taper-shank reduction sleeve BT30,

Facemilling cutting rod BT30, Pneumatic rivet, precision mold clamp, suit spring collet CNC

dividing head (four axis)

Whirling samples show:

- Q: What is the meaning of a motor

- This structure is easy to disassemble, each control panel is highly integrated, so that the reliability is greatly improved, and easy to repair, replace.

- Q: How does the CNC lathe front knife and rear turret programming differ

- Y positive direction to the negative direction to determine the positive direction of the X axis, and then in the XZ plane to determine the direction of G02 and G03 on it, the front tool holder Y-axis direction down, rear knife Y-axis positive direction

- Q: What is the top degree of the lathe?

- Front of the front of the lathe can be directly installed in the lathe spindle cone hole, the front tip and the workpiece with the rotation, no relative movement, so no need to quench. The lathes can sometimes be clamped with a three-jaw self-center chuck with a self-made steel with a 60 degree taper angle. In order to prevent the rotation of the axial force in the role of the top displacement

- Q: What is the lathe

- The lathe is mainly used for machining shafts, plates, sleeves and other workpieces with slewing surfaces, and is the most widely used machine in machinery manufacturing and repair plants.

- Q: What is the cause of a round trip in a CNC lathe?

- CNC lathe round beating reasons:

- Q: Lathe X Y Z-axis How to distinguish between positive and negative directions (attention to detail)

- , The direction perpendicular to the workpiece mounting surface is taken as the direction of the Z-axis.

- Q: What is 50 lathes

- That is, 20 indicates that the maximum turning diameter on the lathe is 20 * 10 = 200 mm

- Q: How the first lathe is made in China

- This ancient method evolved into a rope on the pulley around the rope, the rope frame in the curved arched elastic rod, push back and forth so that the processing object rotation to turn, this is the "bow lathe."

- Q: In the NC lathe fixture once a workpiece, processing multiple parts, the program how to write?

- There are two ways, one is the first time to the outer hole inside the car and then cut off with m98, m99 tone subroutine, but on the two words more than once again.

- Q: How the number of machining parts of CNC lathe is cleared

- Now the new CNC machine fanuc 0i above the system can be in the location of the screen, while pressing "N" and "delete" can be zero.

Send your message to us

Multi-purpose Small Mini CNC Milling Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords