CMAX High -temprature-resistant Flexitank

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 7000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

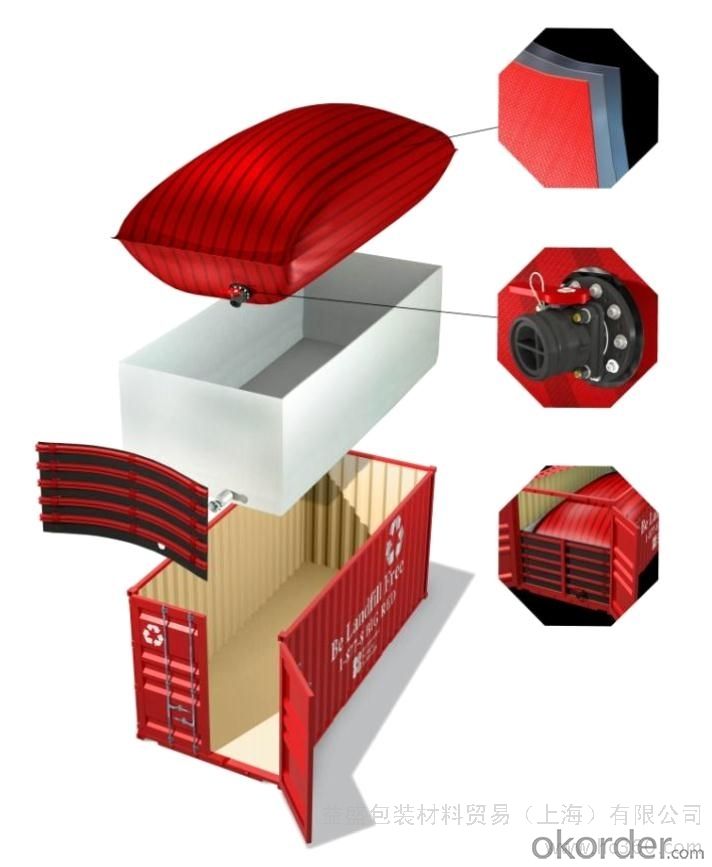

1、CMAX High -temprature-resistant Flexitank Product Description:

High -temprature-resistant Flexitank is a flexitank with CMAX new heat-resistant material technology, is specially designed bulk liquid cargo with high filling temperature like liquid bitumen/asphalt; it is suitable for all kinds of liquid road bitumen, liquid chemicals with high filling temperature.

2、Features and Benefits:

uCompared with general-purpose flexitank, CMAX high-temprature-resistant lexitank could withstand 60-90℃ filling temprature, high pressure resistant,strong and durable.

uLoad 30% more than with drums per 20ft container

uSave 50%+ package positioning cost than with drums per 20ft container

uThe inner bag could be melted into bitumen, no damage to bitumen quality, environment friendly and convenient for operation.

3、Application:

Suitable for all kinds of liquid road bitumen,chemicals with high filling temperature.

4、Features and Benefits:

u More convenient, simple, and economical compared to the conventional tank packaging

u Foldable with strong impermeability, no leakage, anticorrosive, and cleaning-cost saving

u Increase loading capacity, shorten transport time, and improve the efficiency of transport

- Q: Is it really safe to change containers to liquid containers?

- That is, including containers in the lining of the container lining, the door has a full set of baffle products.

- Q: What reason is the container loaded?

- General cargo loading will appear this kind of circumstance, such as steel, if both sides of the wall without box wood pad, finished goods or packing process, it is easy to cause the box wall on both sides of the outer drum.

- Q: What kind of containers do you have for transporting petrochemical products?

- Then fill the bag directly with liquid

- Q: The company shipped the goods in container liquid bags, and the liquid bag manufacturers suggest that we buy Marine Insurance to cover the losses caused by the accident during the transportation, and all risks?

- How much is the cost? You should ask the insurance company directly. The premium is based on your value.We can't figure it out.Only formula, generally speakingAll risks premium rate = 0.4%, war risk premium rate = 0.03%The rate for FPA and WPA is 0.1%Take a computer and count it yourself. It's not difficult, you know it once.

- Q: Why do manufacturers still use drums instead of container bags?

- Since the shipment of cans and packaging barrels is the traditional main mode of transport of bulk liquid, but shipping cans and packaging barrels of high return and purchase, maintenance and cleaning expenses often makes the enterprise logistics cost is high, but also adversely affect the country's resource utilization and environmental protection.

- Q: What is the container fluid bag? What's the use of it?

- It has been widely used in various fields such as chemical industry, petroleum, food, feed, agricultural products and so on. The tank, can replace the expensive in non hazardous liquid transportation on drums and other traditional packaging. All container companies are available.

- Q: Which container is a good container?

- LAF is committed to becoming a trusted, sustainable logistics package provider. In the industry, product quality, customer service and business services, the overall brand reputation is one of the best, we do not own, we talk with the fact, the current LAF customers are well-known listed companies, or 500 companies, Coca-Cola, ADM, petroleum, petrochemical and so on

- Q: Brief introduction of container liquid bag

- Compared to the traditional tank, the liquid bag can carry more goods and can load more than 40% of the original container, so the number of containers needed can be reduced, thus saving the capital.(3) BULKHEAD can be installed in the liquid bag, equal to a heat sink, and its maximum temperature is 80 degrees. This liquid, which has a temperature requirement, is very good. It can heat up these special liquids. This is a traditional pot can not do.(4) the operation of the liquid bag is very simple. It takes only a few people and a few tubes to complete the operation, while the traditional IBC and the tank require dozens of workers to put the things in order. Second, its handling is also very simple. The liquid can be loaded from the top valve through the pipe and then released from the bottom valve through the pipe when it is released.(5) besides the benefits of cost savings mentioned above, the biggest advantage of liquid bags is that they are inexpensive. The price is nearly half that of the traditional method. Leakage: very responsible to say, liquid bag soft packaging material, leakage inevitable. Is also the biggest obstacle to the use of liquid bags. There are many reasons for leakage, which are divided into: liquid bag design defects; liquid bag production quality defects; improper use (including foreign bodies, scratches, fierce collisions, etc.).What can be done now is to improve design, strictly monitor quality, and strengthen customer guidance, thereby reducing the risk of leakage. Through rapid network response, reasonable insurance claims can further cover possible risks.Strengthen customer guidance, rational use of liquid bags; at the same time to strengthen communication and transportation enterprises, reasonable operation of container fluid bags, thereby reducing the risk generated.

- Q: How is the container liquid bag unloading process carried out?

- Is to open the liquid bag top and safe, and will transport pipeline joint and liquid bag valve connection and buckle, and then check whether it is safe and stable. Thus, the information of the container liquid bag is ensured to have good safety effect. Then, we must fix the hose with the external connection, so that we can work efficiently and effectively correct our ability. The fourth is to begin unloading the cargo until the discharge is completed and the whole must be guarded.

- Q: What kind of general chemicals can be packed in container bags?

- Food categoryWine, edible oil, concentrated juice, food additives, sorbitol, palm oil, soy sauce, Yellow Wine, mineral water, malt extract, syrup, etc.

Send your message to us

CMAX High -temprature-resistant Flexitank

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 7000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords